In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications

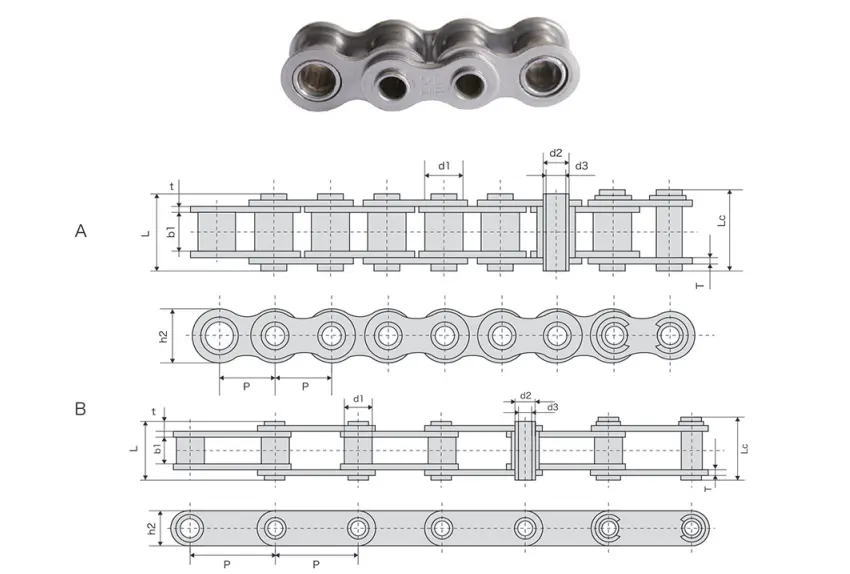

The 60HPSS Stainless Steel Hollow Pin Chain features the following specifications:

- Material: Stainless Steel

- Type: Hollow Pin Chain

- Strength: 60HPSS

| Chain No |

Pitch | Bush? diameter | Width between inner plates |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Breaking Load |

Ağırlık per meter |

Type |

| P | d1 | bl | d2 | d3 | L | LC | h2 | T | Q | q | ||

| max | min | max | min | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

giriiş

The 60HPSS Stainless Steel Hollow Pin Chain is a high-quality, durable chain that is designed for use in a variety of industrial applications. This chain is made from high-grade stainless steel, which ensures that it is resistant to corrosion and can withstand harsh environments. It is also designed with hollow pins, which helps to reduce its weight and make it easier to handle.

Features and Benefits

1. Corrosion Resistance

One of the key features of the 60HPSS Stainless Steel Hollow Pin Chain is its resistance to corrosion. The high-grade stainless steel used in its construction ensures that it can withstand exposure to harsh chemicals and environments without rusting or deteriorating over time. This makes it an ideal choice for use in applications where corrosion resistance is critical.

2. Hollow Pin Design

The hollow pin design of this chain is another key feature. By using hollow pins instead of solid ones, the weight of the chain is reduced while maintaining its strength. This makes it easier to handle and transport, which can help to reduce the risk of worker injury and improve efficiency in industrial applications.

3. Durability

The 60HPSS Stainless Steel Hollow Pin Chain is also highly durable. Its construction from high-grade stainless steel ensures that it can withstand heavy loads and constant use without breaking or deteriorating. This makes it a reliable choice for use in demanding industrial applications.

4. Versatility

One of the key benefits of this chain is its versatility. It is suitable for use in a wide range of industrial applications, from conveying systems to material handling equipment. Its strength, durability, and corrosion resistance make it an ideal choice for use in harsh environments where other types of chain may not be suitable.

5. Easy to Maintain

Finally, the 60HPSS Stainless Steel Hollow Pin Chain is easy to maintain. Its simple design and high-quality construction ensure that it can be cleaned and lubricated easily, which helps to extend its lifespan and reduce the risk of downtime due to maintenance issues.

Conclusion

The 60HPSS Stainless Steel Hollow Pin Chain is a high-quality, durable chain that is designed for use in a wide range of industrial applications. Its corrosion resistance, hollow pin design, durability, versatility, and ease of maintenance make it an ideal choice for use in demanding environments where other types of chain may not be suitable. If you are looking for a reliable, high-quality chain for your industrial application, the 60HPSS Stainless Steel Hollow Pin Chain is an excellent choice.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the sales agent of Ever-power Group in the Netherlands. We take pride in offering the exceptional 60HPSS Stainless Steel Hollow Pin Chain, which showcases our unique selling points. Our stainless steel roller chains are renowned for their outstanding quality, superior service, and exceptional durability. With our robust production capabilities, we ensure that each chain meets the highest standards. In addition to the 60HPSS chain, we also provide a wide range of other stainless steel roller chains to cater to diverse needs. Choose us for reliable and top-notch roller chains that will exceed your expectations.

Sprockets for Sale

When it comes to finding the perfect match for your 60HPSS Stainless Steel Hollow Pin Chain, our company offers a wide range of different types of sprockets for sale. Whether you need a standard roller chain sprocket, double pitch sprocket, or a custom-designed sprocket, we have the solution for you.

Our sprockets are made from high-quality materials to ensure durability and performance. They are precision-engineered to provide a reliable and efficient power transmission system. With our extensive inventory, you can find the right size, tooth count, and bore size to meet your specific requirements.

By choosing our sprockets, you can expect smooth and precise chain engagement, reducing wear and extending the lifespan of your chain. Our sprockets are designed to withstand demanding applications, including heavy-duty industrial machinery, conveyor systems, and agricultural equipment.

Take a look at our selection of sprockets below:

Ek Bilgiler

| Editor | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...