In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

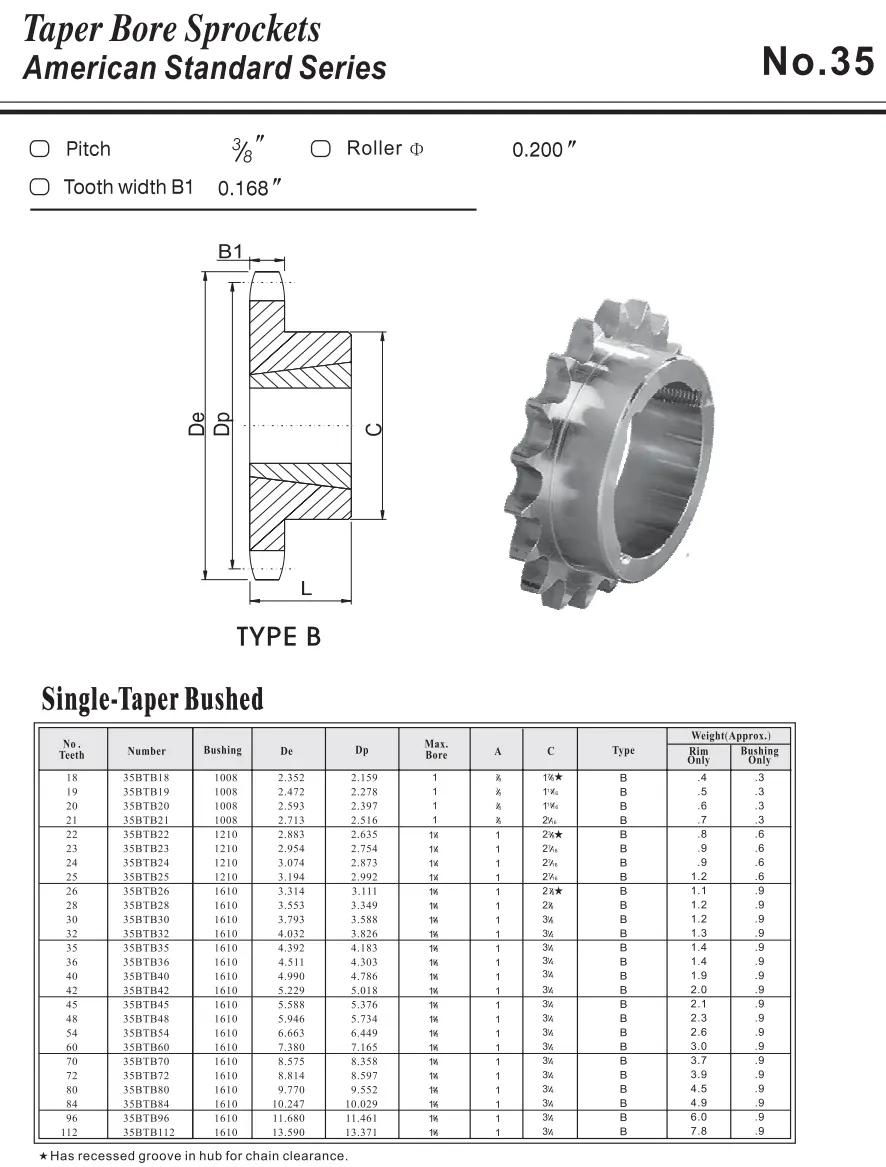

#35 3/8″ Taper Bore Sprocket

The #35 3/8″ Taper Bore Sprocket is designed for durability and efficient power transmission in various applications. Constructed from high-quality materials, it ensures reliable performance and longevity. Its tapered bore allows for easy installation on shafts, making it an ideal choice for machinery requiring precision and dependability in motion. Perfect for industrial use.

#35 3/8" Taper Bore Sprocket Specifications

#35 3/8" Taper Bore Sprocket is an essential component commonly employed in power transmission systems. This specialized sprocket is distinguished by its tapered bore design, which allows for a secure and stable fit on the shaft using a set screw. The efficient design facilitates the effective transfer of power and motion between rotating shafts and chains, making it a vital part of various mechanical systems.

Features and Functions

- Easy to install: The innovative tapered bore design, along with the set screw mechanism, allows for straightforward installation onto a shaft without the need for a traditional keyway, which can complicate the process.

- High precision positioning: This sprocket guarantees accurate positioning, effectively preventing slippage during operation and ensuring consistent performance.

- Wide applicability: Taper Bore Sprockets are available in a variety of sizes, making them versatile and adaptable for numerous industrial applications.

- Güvenilirlik: The Taper Bore Sprocket is recognized for its reliability within power transmission systems, requiring minimal maintenance to function effectively.

- Low maintenance cost: With its low maintenance requirements, the Taper Bore Sprocket enables users to save both time and money, enhancing operational efficiency.

The key benefit of the Taper Bore Sprocket lies in its simple installation and disassembly process. The set screw securely tightens around the shaft, providing a firm fit while also allowing for easy removal without causing any damage to the shaft, which is crucial for maintenance and repair activities.

Installation and Disassembly Process

- Prepare tools and materials: Gather all necessary tools and materials for the installation process, including the Taper Bore Sprocket, bushing, set screws, and a torque wrench to ensure a proper fit.

- Clean the shaft and sprocket surface: Make sure that both the shaft and sprocket surfaces are thoroughly cleaned to remove any dirt, debris, or rust, which could hinder a smooth installation.

- Place the Taper Bore bushing: Carefully slide the Taper Bore bushing onto the shaft and secure it in place using the set screws to prevent any movement.

- Install the sprocket: Slide the Taper Bore Sprocket onto the bushing, ensuring it aligns correctly with the shaft. Subsequently, tighten the set screws to the specified torque level to achieve a secure fit.

- Tighten the locking nut: Utilize a torque wrench to tighten the locking nut according to the required torque specifications, ensuring everything is firmly in place.

Manufacturing Process

The manufacturing process of the Taper Bore Sprocket encompasses multiple stages to guarantee a high-quality final product. The key steps in this procedure include:

- Prepare raw materials: The materials used in the production of Taper Bore Sprockets typically involve carbon steel or alloy steel, which are known for their strength and durability.

- Cutting: The selected raw material is precisely cut into the desired shape and size, forming the initial structure of the sprocket.

- Forging or casting: The cut material is then forged or cast into the rough shape of the sprocket, providing the fundamental form needed for further processing.

- Machining: The sprocket undergoes machining to refine its dimensions, ensuring it meets the specified requirements for functionality.

- Teeth rolling: The teeth of the sprocket are rolled to achieve an accurate fit with the corresponding chain, which is essential for effective power transmission.

- Heat treatment: To enhance hardness and durability, the sprocket is subjected to heat treatment, improving overall performance and longevity.

- Surface treatment: A protective surface coating is applied to guard against rust and corrosion, extending the life of the sprocket in various environments.

- Quality inspection: Finally, the completed sprocket undergoes rigorous quality inspections to ensure it adheres to the necessary specifications and industry standards.

Sprockets Supplier in the Netherlands

RP Techniek BV acts as the sales agent for Ever-power Group in the Netherlands, offering high-quality sprockets and related products tailored to meet a diverse range of industrial needs. Our featured product is the #35 3/8" Taper Bore Sprocket, renowned for its durability and precision engineering. This sprocket is designed to integrate seamlessly with various chain types, ensuring optimal performance across machinery and equipment.

In addition to our standard offerings, we also specialize in custom solutions that cater to our clients' specific requirements. Our dedicated team is committed to providing high-quality, non-standard sprockets based on customer designs or samples. We warmly invite all clients to reach out with their unique customization needs.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...