In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications

- Product Name: 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain

- Chain Size: 24BSS-2

- Chain Type: Duplex

- Pitch: Short Pitch

- Material: Stainless Steel

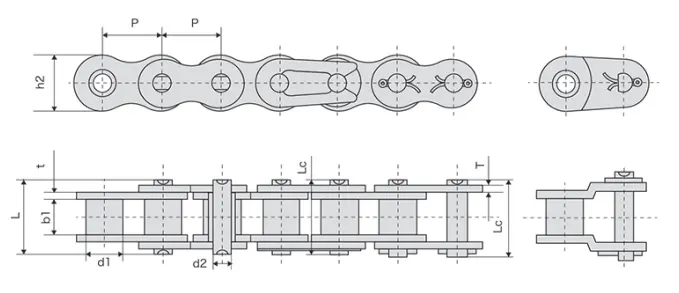

| simplex Stainless Steel Roller Chains | |||||||||||

| DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | t/T(max) | Q(min) | Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | |

| 05BSS-1 | 8 | 5 | 3 | 2.31 | 8.2 | 8.9 | 7.1 | 0.8 | 3 | 3.54 | 0.2 |

| *06BSS-1 | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.1 | 8.2 | 1.3 | 5.4 | 6.24 | 0.41 |

| 08BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 1.6 | 10.8 | 11.64 | 0.69 |

| 10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 1.7 | 13.44 | 16.5 | 0.93 |

| 12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 1.85 | 17.4 | 19.3 | 1.15 |

| 16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 4.15/3.1 | 3.6 | 43.68 | 2.71 |

| 20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 41.3 | 45 | 26.4 | 1.5/3.5 | 57 | 64.02 | 3.7 |

| 24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 57.8 | 33.2 | 6.0/4.8 | 96 | 106.8 | 7.1 |

| 28BSS-1 | 44.45 | 27.94 | 30.99 | 15.9 | 65.1 | 69.5 | 36.7 | 7.5/6.0 | 120 | 133.2 | 8.5 |

| 32BSS-1 | 50.8 | 29.21 | 30.99 | 17.81 | 66 | 71 | 42 | 7.0/6.0 | 150 | 166.5 | 10.25 |

| 40BSS-1 | 63.5 | 39.37 | 38.1 | 22.89 | 82.2 | 89.2 | 52.96 | 8.5/8.0 | 213 | 236.4 | 16.35 |

| 48BSS-1 | 76.2 | 48.26 | 45.72 | 29.24 | 99.1 | 107 | 63.8 | 12.0/10.0 | 336 | 372.96 | 25 |

|

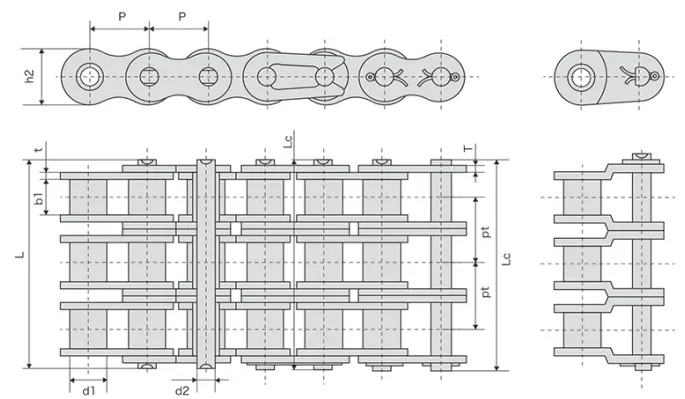

|||||||||||||||||||||||||

| DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | ||||||||||||||

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | t/T(max) | Pt | Q(min) | Q0 | q | ||||||||||||||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||||||||||||||

| 05BSS-2 | 8 | 5 | 3 | 2.31 | 13.9 | 14.5 | 7.1 | 0.8 | 5.64 | 4.68 | 6.1 | 0.33 | |||||||||||||

| *06BSS-2 | 9.525 | 6.35 | 5.72 | 3.28 | 23.4 | 24.4 | 8.2 | 1.3 | 10.24 | 10.14 | 11.22 | 0.77 | |||||||||||||

| 08BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31.2 | 32.2 | 11.8 | 1.6 | 13.92 | 19.2 | 23.22 | 1.34 | |||||||||||||

| 10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 36.1 | 37.5 | 14.7 | 1.7 | 16.59 | 26.7 | 33.72 | 1.84 | |||||||||||||

| 12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 42 | 43.6 | 16 | 1.85 | 19.46 | 34.68 | 39.66 | 2.31 | |||||||||||||

| 16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 68 | 69.3 | 21 | 4.15/3.1 | 31.88 | 63.6 | 79.8 | 5.42 | |||||||||||||

| 20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.8 | 81.5 | 26.4 | 4.5/3.5 | 36.45 | 102 | 126.72 | 7.2 | |||||||||||||

| 24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.7 | 106.2 | 33.2 | 6.0/4.8 | 48.36 | 168 | 191.52 | 13.4 | |||||||||||||

| 28BSS-2 | 44.45 | 27.94 | 30.99 | 15.9 | 124.6 | 129.1 | 36.7 | 7.5/6.0 | 59.56 | 216 | 244.08 | 16.6 | |||||||||||||

| 32BSS-2 | 50.8 | 29.21 | 30.99 | 17.81 | 124.6 | 129.6 | 42 | 7.0/6.0 | 58.55 | 270 | 305.1 | 21 | |||||||||||||

| 40BSS-2 | 63.5 | 39.37 | 38.1 | 22.89 | 154.5 | 161.5 | 52.96 | 8.5/8.0 | 72.29 | 378 | 427.14 | 32 | |||||||||||||

| 48BSS-2 | 76.2 | 48.26 | 45.72 | 29.24 | 190.4 | 198.2 | 63.8 | 12.0/10.0 | 91.21 | 600 | 678 | 50 | |||||||||||||

| DIN/ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | t/T(max) | Pt | Q(min) | Q0 | Q0 | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | |

| 05BSS-3 | 8 | 5 | 3 | 2.31 | 19.5 | 20.2 | 7.1 | 0.8 | 5.64 | 6.66 | 8.28 | 0.48 |

| *06BSS-3 | 9.525 | 6.35 | 5.72 | 3.28 | 33.5 | 34.6 | 8.2 | 1.3 | 10.24 | 14.94 | 18.06 | 1.16 |

| 08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45.1 | 46.1 | 11.8 | 1.6 | 13.92 | 28.5 | 34.68 | 2.03 |

| 10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 54.1 | 14.7 | 1.7 | 16.59 | 40.02 | 50.7 | 2.77 |

| 12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 63.1 | 16 | 1.85 | 19.46 | 52.02 | 61.08 | 3.46 |

| 16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.8 | 101.2 | 21 | 4.15/3.1 | 31.88 | 96 | 122.22 | 8.13 |

| 20BSS-3 | 31.75 | 16.05 | 19.56 | 10.19 | 114.2 | 117.9 | 26.4 | 4.5/3.5 | 36.45 | 150 | 174 | 10.82 |

| 24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.1 | 154.6 | 33.2 | 6.0/4.8 | 48.36 | 255 | 295.8 | 20.1 |

| 28BSS-3 | 44.45 | 17.94 | 30.99 | 15.9 | 184.2 | 188.7 | 36.7 | 7.5/6.0 | 59.56 | 318 | 365.7 | 24.92 |

| 32BSS-3 | 50.8 | 29.21 | 30.99 | 17.81 | 183.2 | 188.2 | 42 | 7.0/6.0 | 58.55 | 402 | 462.3 | 31.56 |

| 40BSS-3 | 63.5 | 39.37 | 38.1 | 22.89 | 226.8 | 233.8 | 52.96 | 8.5/8.0 | 72.29 | 570 | 655.5 | 48.1 |

| 48BSS-3 | 76.2 | 48.26 | 45.72 | 29.24 | 281.6 | 189.4 | 63.8 | 12.0/10.0 | 91.21 | 900 | 979.5 | 75 |

1. Overview

The 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain is a high-quality and durable chain designed for various industrial applications. This roller chain offers superior performance and reliability, making it an ideal choice for demanding environments.

2. Construction

The 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain is constructed using premium-grade stainless steel materials. This ensures excellent corrosion resistance, making the chain suitable for use in harsh conditions where exposure to moisture or chemicals is a concern.

2.1 Roller Design

The chain features specially designed rollers that offer smooth and efficient operation. These rollers are engineered to minimize friction and maximize load distribution, resulting in reduced wear and improved chain life.

2.2 Pin and Bushing System

The pin and bushing system of the 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain is precision-engineered to provide exceptional strength and durability. This system ensures smooth articulation between the chain components, minimizing noise and vibration during operation.

3. Performance

The 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain delivers outstanding performance in various applications. Its high tensile strength and excellent resistance to wear make it suitable for conveying heavy loads and operating under demanding conditions.

3.1 Load Capacity

With its robust construction and superior material quality, this roller chain has a high load-carrying capacity. It can reliably handle heavy loads without compromising performance or safety.

3.2 Wear Resistance

The 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain is designed to withstand prolonged use and resist wear. It features hardened components that minimize elongation and maintain dimensional stability, ensuring long-lasting performance.

4. Applications

The versatility of the 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain makes it suitable for a wide range of applications, including:

4.1 Food Processing

Due to its stainless steel construction, this roller chain is well-suited for use in food processing industries where hygiene and corrosion resistance are critical factors.

4.2 Packaging Machinery

The reliable performance and durability of this roller chain make it an ideal choice for packaging machinery, ensuring smooth and efficient operation in high-speed production lines.

4.3 Chemical Industry

Thanks to its corrosion-resistant properties, the 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain is suitable for use in the chemical industry, where exposure to corrosive substances is common.

5. Conclusion

The 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain is a premium-quality chain that offers exceptional performance, durability, and corrosion resistance. Its robust construction and reliable operation make it an excellent choice for various industrial applications. Whether you need a chain for food processing, packaging machinery, or the chemical industry, this roller chain delivers the reliability and performance you require.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. Our company specializes in providing high-quality stainless steel roller chains, including the 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain.

Our stainless steel roller chains are known for their durability and strength, making them suitable for use in various industries, including food processing, packaging, and pharmaceuticals. Our products are made from high-grade stainless steel and are designed to withstand heavy loads and harsh environments. We take pride in our commitment to quality and customer satisfaction, ensuring that our clients receive the best products and services.

Apart from the 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain, we also offer a wide range of other stainless steel roller chains for sale. Our products come in various sizes and designs to meet our clients' specific needs. We guarantee that all our products are made to the highest standards and undergo rigorous quality control checks before leaving our factory.

At RP Techniek BV, we have a team of experienced professionals who are committed to providing exceptional customer service. Our staff is knowledgeable in all aspects of stainless steel roller chains and can help you find the perfect product for your needs. We also offer custom solutions to meet our clients' unique requirements.

Please see the attached image for a quick overview of our manufacturing capabilities.

Sprockets for Sale

The 24BSS-2 Duplex Short Pitch Stainless Steel Roller Chain is perfectly complemented by our wide range of sprockets. We offer various types of sprockets to suit your needs. Whether you require standard, custom, or specialty sprockets, our company has got you covered.

Our sprockets are made from high-quality materials and are designed to provide optimal performance and durability. We understand the importance of reliable and efficient sprockets in ensuring smooth chain operation. That is why we offer a diverse selection of sprockets to meet the requirements of different industries and applications.

From standard single and double sprockets to taper lock and idler sprockets, we have a comprehensive range of options available. Our sprockets come in various sizes, tooth counts, and bore diameters to accommodate different chain specifications.

At our company, we prioritize customer satisfaction and aim to provide you with the best sprockets that meet your specific needs. Whether you need sprockets for industrial machinery, agricultural equipment, or any other application, our dedicated team is ready to assist you in finding the perfect match.

For more information and to explore our full range of sprockets, please visit our website or contact our sales team. Take a look at the image below for a glimpse of our sprocket collection:

We look forward to serving you and providing top-quality sprockets for your chain applications.

Ek Bilgiler

| Editor | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...