In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

16B-1-2-3 1″ Taper Lock Sprocket

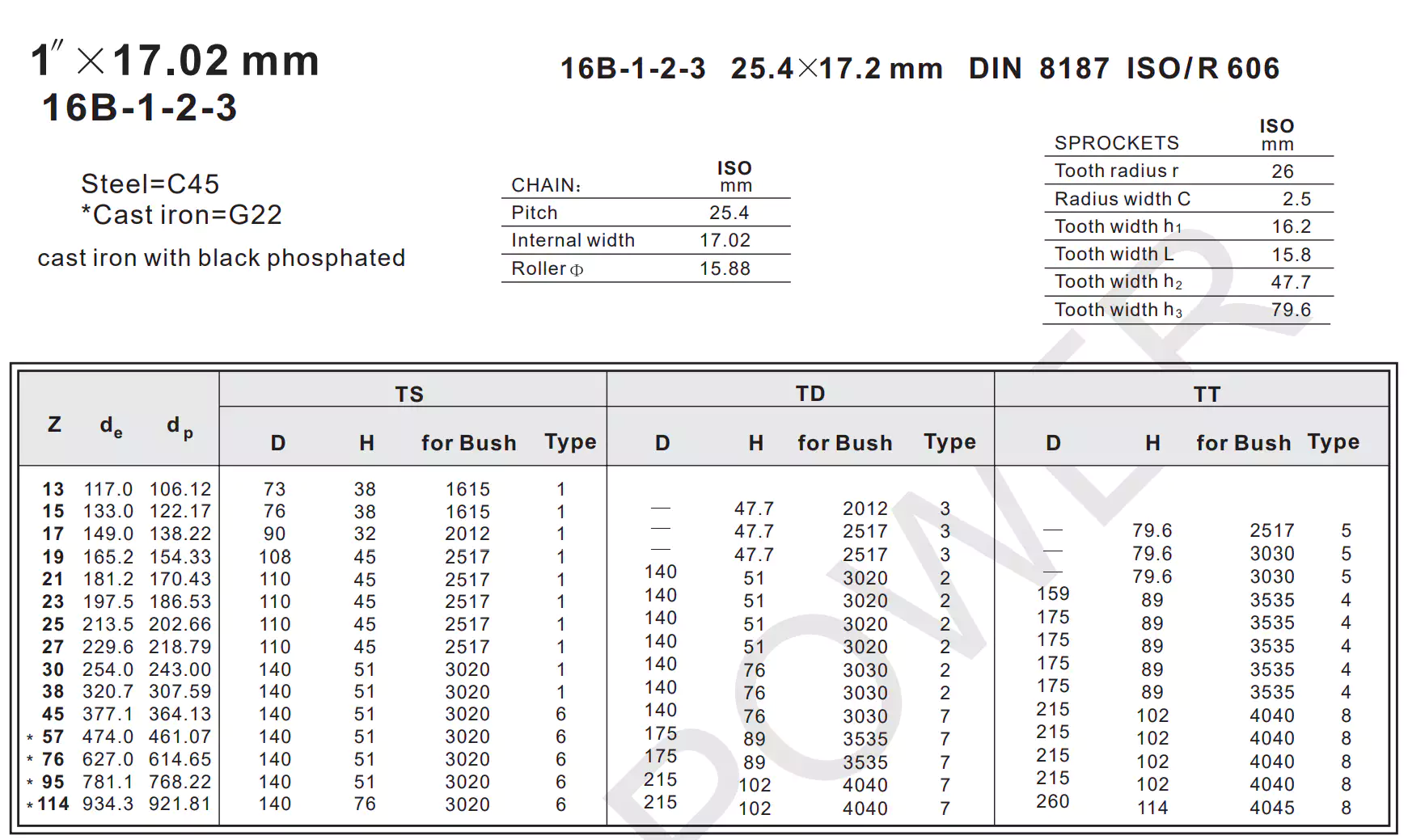

The 16B-1-2-3 1″ Taper Lock Sprocket is designed for efficient power transmission in various mechanical applications. Its taper lock mechanism ensures easy installation and removal, while providing a secure fit on shafts. Made from high-quality materials, this sprocket offers durability and reliable performance, making it ideal for industrial and agricultural use.

Details and Parameters of Taper Lock Sprocket 16B-1-2-3

The Taper Lock Sprocket 16B-1-2-3, adhering to European standards, is a crucial component used in various power transmission applications. Featuring a unique tapered bore design and a bushing, this sprocket can be easily mounted onto shafts without requiring additional keys or set screws. Its design promotes versatility, making it a popular choice across sectors such as mining, construction, agriculture, and manufacturing. The ease of installation and robust performance make this sprocket a valuable asset in many industrial setups.

Definition and Basic Structure of Taper Lock Sprocket

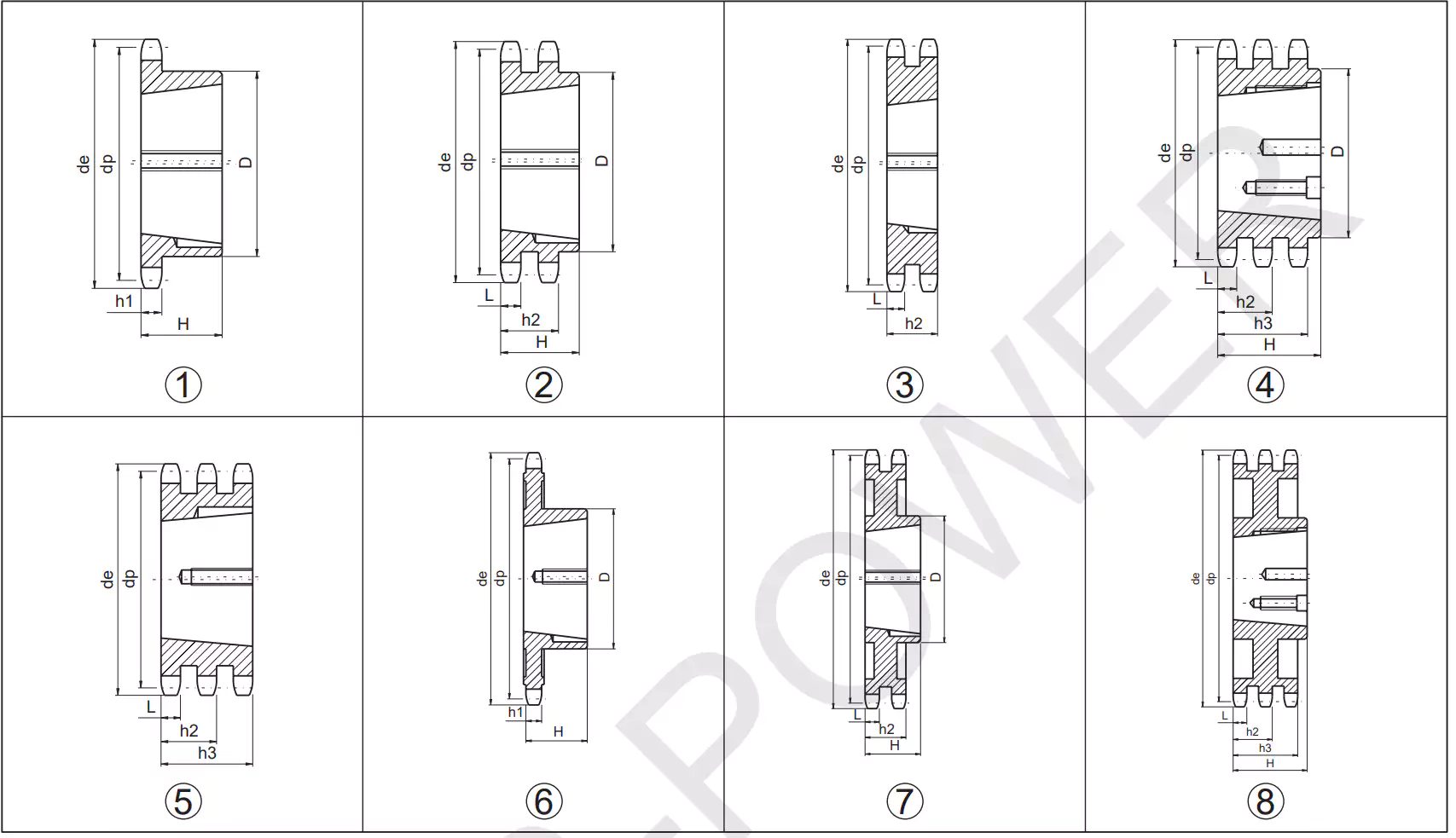

A Taper Lock Sprocket is defined by its tapered bore and an accompanying bushing. The tapered bore enables straightforward mounting on a shaft, eliminating the need for additional keys or set screws, thus streamlining installation. The bushing serves as a connector between the sprocket and the shaft, ensuring a secure and accurate fit. The primary structure of a taper lock sprocket comprises a hub, teeth, and a bore with a taper. The hub is the central component connecting to the bushing, while the teeth engage with the chain, facilitating power transmission.

Features and Benefits of Taper Lock Sprocket

- Easy to install: The Taper Lock Sprocket allows for quick and simple mounting on a shaft, streamlining the installation process without the need for extra keys or set screws.

- High precision positioning: Thanks to the tapered bore and bushing, it provides a secure fit, ensuring the sprocket is accurately positioned on the shaft for optimal performance.

- Wide applicability: This sprocket is ideal for a variety of applications across multiple industries, demonstrating its versatility.

- Güvenilirlik: Designed for durability, the Taper Lock Sprocket establishes a dependable connection between the sprocket and the shaft, ensuring long-lasting performance.

- Low maintenance cost: Its construction requires minimal maintenance, which contributes to lower overall maintenance expenses, making it an economically viable choice.

The Taper Lock Sprocket's main advantages lie in its straightforward installation and disassembly. To mount the sprocket on a shaft, follow these simple steps:

- Prepare tools and materials: Collect all required tools and materials before beginning the installation process to ensure efficiency.

- Clean shaft and sprocket surface: Always check that the surfaces of both the shaft and sprocket are clean, eliminating any debris or contaminants that could interfere with the fit.

- Place taper lock bushing: Carefully insert the taper lock bushing into the bore of the sprocket, ensuring it fits snugly.

- Install sprocket: Slide the sprocket onto the shaft, making sure that the teeth properly engage with the chain for effective power transmission.

- Tighten locking nut: Complete the installation by securely tightening the locking nut, ensuring the sprocket remains in place during operation.

Manufacturing Process of Taper Lock Sprocket

The production of the Taper Lock Sprocket involves several essential steps:

- Prepare raw materials: Start with high-quality raw materials, such as steel or cast iron, that will form the basis of the sprocket.

- Cutting: Use various cutting tools to shape the raw materials to the desired dimensions and form.

- Forging or casting: The material is either forged or cast into a rough shape resembling the final sprocket.

- Machining: This step involves machining the sprocket to achieve the precise dimensions and contour required for optimal functionality.

- Rolling: The sprocket teeth are rolled to ensure they meet accuracy and precision standards.

- Heat treatment: Subject the sprocket to heat treatment processes to enhance its hardness and overall durability.

- Surface treatment: Apply a protective surface treatment, such as plating or painting, to guard against corrosion and extend the product's life.

- Quality inspection: Finally, conduct thorough inspections to verify the quality and accuracy of the sprocket before it is put into service.

Sprockets Supplier in Holland

RP Techniek BV serves as the Dutch sales representative for the Ever-power Group, a top manufacturer of power transmission products. We specialize in providing high-quality sprockets, including the 16B-1-2-3 1" Taper Bore Sprocket. This specific sprocket is designed for both durability and efficiency, making it suitable for a range of industrial applications. Our sprockets are crafted with precision engineering to guarantee an ideal fit and optimal operational performance.

In addition to our standard selection of sprockets, we also offer custom solutions tailored to meet specific customer requirements. We encourage customers to bring their designs or samples to us for personalized solutions that cater to their unique needs.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...