In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Helical Gearmotors for Wheel Brushes in Automatic Car Washing Machine

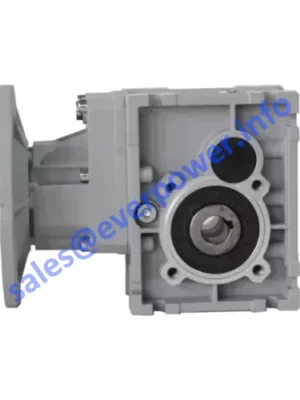

The EPRGV040 Series Helical Gear Reducer is designed primarily for use in the wheel brush of car washers. Featuring a two-stage helical gear structure, it offers higher transmission efficiency, a more compact design, and a wider range of ratio options compared to traditional worm reducers. Additionally, its simple construction ensures greater durability and reliability.

Helical Gearmotors for Wheel Brushes in Automatic Car Washing Equipment

Helical gearmotors are a type of gear motor used in various mechanical applications, including automatic car washing machines. These gearmotors are essentially a combination of a helical gearbox and an electric motor. They are designed to transmit power and motion to the wheels of an automatic car washing machine.

Specifications of EPRGV040 Automatic Car Washer Helical Gearbox

| Type | Ratio | Flange | Power |

| EPRGV040 | 6.57-56.93 | 71B14 | 0.25kw,0.37kw,0.55kw |

| Type | i | n2/r/min | Mn2/Nm | sf | P1/kw |

| EPRGV040 | 6.57 | 213 | 11 | 6.4 | 0.25 |

| 213 | 16 | 4.4 | 0.37 | ||

| 213 | 23 | 2.9 | 0.55 | ||

| 9.78 | 143 | 16 | 5.1 | 0.25 | |

| 143 | 23 | 3.4 | 0.37 | ||

| 143 | 34 | 2.3 | 0.55 | ||

| 12.62 | 111 | 20 | 5.1 | 0.25 | |

| 111 | 30 | 3.5 | 0.37 | ||

| 111 | 45 | 2.3 | 0.55 | ||

| 15.44 | 91 | 25 | 5 | 0.25 | |

| 91 | 37 | 3.3 | 0.37 | ||

| 91 | 54 | 2.2 | 0.55 | ||

| 19.88 | 70 | 32 | 3.7 | 0.25 | |

| 70 | 47 | 2.5 | 0.37 | ||

| 70 | 70 | 1.7 | 0.55 | ||

| 23.99 | 58 | 38 | 3.1 | 0.25 | |

| 58 | 57 | 2.1 | 0.37 | ||

| 58 | 85 | 1.4 | 0.55 | ||

| 29.67 | 47 | 48 | 2.5 | 0.25 | |

| 47 | 70 | 1.7 | 0.37 | ||

| 47 | 105 | 1.1 | 0.55 | ||

| 35.75 | 39 | 57 | 2.1 | 0.25 | |

| 39 | 85 | 1.4 | 0.37 | ||

| 39 | 126 | 0.9 | 0.55 | ||

| 38.2 | 37 | 61 | 1.9 | 0.25 | |

| 37 | 91 | 1.3 | 0.37 | ||

| 44.22 | 32 | 71 | 1.6 | 0.25 | |

| 32 | 105 | 1.1 | 0.37 | ||

| 56.93 | 25 | 91 | 1.3 | 0.25 | |

| 25 | 135 | 0.9 | 0.37 |

EPRGV040 Automatic Car Washer Helical Reducer Features

- Modular flanges, shafts, and other components designed for universal installation compatibility.

- A wide selection of speed ratios, offering various options to choose from.

- The gear shaft is made of 20CrMnTi, with surface carburization and quenching. The gear hardness is HRC55-58, while the gear shaft hardness is HRC59-62.

- The compact structure allows for installation in diverse environments.

- Equipped with fully synthetic lubricating oil, ensuring a long service life.

- The stainless steel aluminum body, with a spray-coated surface, provides enhanced corrosion resistance.

- NOK oil seals protect both the input and output terminals.

- IP67 protection rating ensures excellent waterproofing, making it suitable for tough environments.

Why are Helical Gear Reducers Used in Car Wash Machines?

Helical gearmotors are typically used in car wash machines because of their ability to provide high torque and speed. They are also highly durable and can withstand frequent use, making them ideal for use in commercial car washes. Additionally, they are designed to be compact and easy to install, which is essential for car wash machines that are often limited in space.

Benefits of Using Helical Reduction Gearbox for Wheel Brushes in Automatic Car Washer

Yüksek Verimlilik

Helical gearmotors are designed to transmit power and motion efficiently, ensuring that the car wash machine operates at optimal performance levels. They are also highly reliable and require less maintenance, which makes them more cost-effective in the long run.

Quiet Operation

Helical gearmotors are also known for their quiet operation, which is essential in environments where noise pollution is a concern. The helical gears reduce noise and vibration, ensuring that the car wash machine operates smoothly and quietly.

Increased Durability

Helical gearmotors are highly durable and can withstand frequent use, making them ideal for use in commercial car washes. They are also designed to require less maintenance, which reduces downtime and increases productivity.

Selection of Helical Gear Unit for Wheel Brushes in Automatic Car Washing Machine

Factors to Consider

- Motor power and speed requirements

- Gear ratio

- Environmental conditions

- Mounting options

- Budget

Installation of Helical Gearbox and Motor

The installation process for a helical gearbox and motor will depend on the specific model and manufacturer. However, generally, the installation process involves the following steps:

- Ensure that the gearbox and motor are compatible

- Mount the gearbox and motor onto the frame of the car wash machine

- Connect the motor to the gearbox using a coupling

- Connect the gearbox to the wheel brushes using a drive shaft

- Test the car wash machine to ensure that it's functioning efficiently

Common Problems with Gearboxes and Their Solutions

Like any mechanical component, gearboxes can experience problems over time. Some common problems include:

- Excessive noise and vibration

- Overheating

- Leaking oil

- Worn or damaged gears

To resolve these issues, it's essential to identify the underlying cause and take appropriate action. Some common solutions include:

- Tightening loose bolts and fasteners

- Replacing worn or damaged gears

- Changing the oil or lubrication

- Adjusting the gear alignment

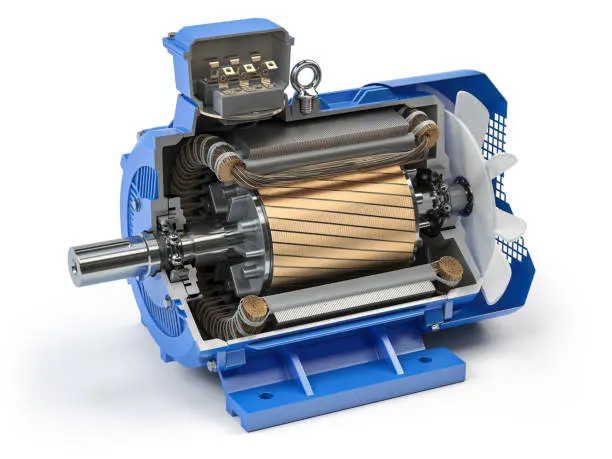

Motors for Car Wash Machine

The motor is a crucial component of a car wash machine, and it works in tandem with the helical gearmotor to provide the required power and motion to the wheels. Without a high-quality motor, the car wash machine will not function efficiently. At RP Techniek BV, we also offer a wide range of motors for car wash machines, ensuring that our customers have access to all the necessary components for their machines.

Hakkımızda

RP Techniek BV is the Netherlands sales agent for the Ever-power Group. We specialize in providing high-quality gearmotors and motors for various mechanical applications, including automatic car wash machines. RP Techniek BV is a leading supplier of helical gearmotors for wheel brushes in automatic car washing machines. We offer a wide range of high-quality gearmotors that are designed to meet the specific needs of car wash machines. Our gearmotors are highly efficient, reliable, and durable, making them ideal for use in commercial car washes. Our products are designed to meet the specific needs of our customers, and we offer the highest level of service and product quality at competitive prices.

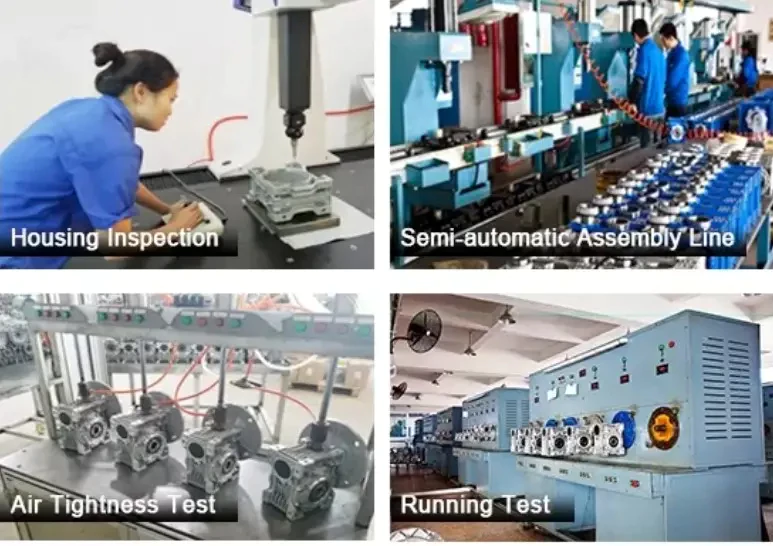

Our Manufacturing Capabilities

At RP Techniek BV, we have state-of-the-art manufacturing facilities that allow us to produce high-quality gearmotors and motors for the automobile industry. We use the latest technology and equipment to ensure that our products are of the highest quality.

Our Customers

Our customers are spread across Europe and the United States, and we have established a reputation for providing high-quality products and exceptional customer service. Our products, including our helical gearmotors and motors for car wash machines, are widely used in various industries, including the automobile industry.

Bize Ulaşın

If you're looking for high-quality helical gearmotors or motors for your automatic car wash machine, look no further than RP Techniek BV. Contact us today to learn more about our products and services and how we can help you take your business to the next level.

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...