The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Aerospace Actuation Systems

Worm gear in aerospace actuation systems is a critical component designed to facilitate precise movement and control in various aerospace applications. These gears are specifically engineered to meet the demanding requirements of aerospace actuators, providing high torque and efficiency. The use of a worm gear for aerospace actuators enables smooth operation in flight actuation systems, ensuring reliability and stability during critical maneuvers. High-precision worm gear for aerospace applications plays a vital role in enhancing performance and safety in aerospace control systems, making it an essential element of modern aviation technology.

Specifications of Worm Gear in Aerospace Actuation Systems

| Şartname | Details |

|---|---|

| Gear Ratio | 20:1 |

| Material | Aluminum Alloy |

| Load Capacity | 500 N |

| Efficiency | 85% |

| Operating Temperature | -40 to 100°C |

| Dimensions | 50mm x 50mm x 30mm |

Why Worm Gears are Suitable for Worm Gear in Aerospace Actuation Systems

- Worm gears in aerospace actuation systems provide high torque output while occupying minimal space, essential for compact actuator designs.

- The unique design of worm gear for aerospace actuators ensures smooth, precise motion control, crucial for high-precision worm gear for aerospace applications.

- Aerospace actuation worm gear uses are prevalent in flight actuation systems, where reliability and efficiency are paramount.

- Worm gear in aerospace control systems offers excellent self-locking capabilities, preventing back-driving and enhancing safety during operation.

How Worm Gears Work in Aerospace Actuation Systems

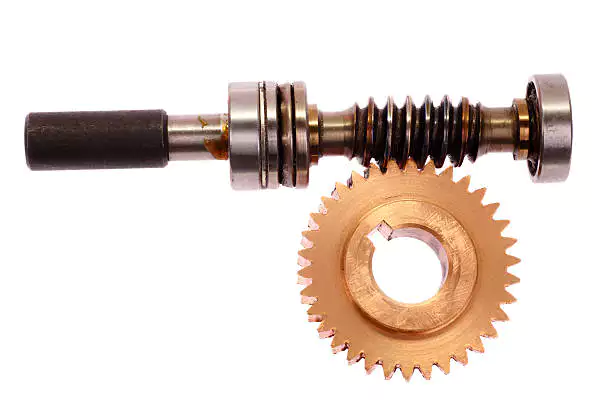

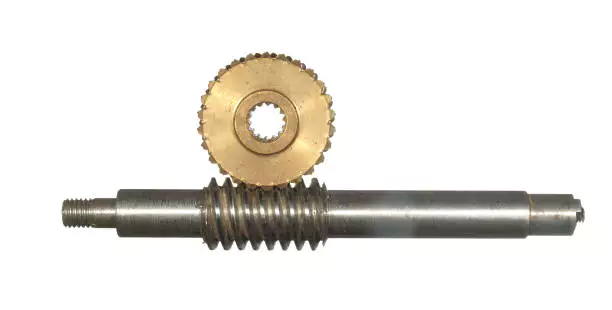

Worm gears play a crucial role in aerospace actuation systems by providing high torque and precise motion control. The worm gear in aerospace actuation systems allows for smooth operation with minimal backlash, essential for applications where precision is paramount. These gears enable aerospace actuators to perform critical functions, such as adjusting flight surfaces or landing gear. The aerospace actuation worm gear uses a unique thread design that converts rotational motion into linear motion effectively. High-precision worm gear for aerospace applications ensures reliability in demanding environments. Furthermore, the worm gear in flight actuation systems enhances the overall performance and safety of aircraft operations. Below is an illustration of a worm gear system used in aerospace control:

Manufacturing Process of Worm Gear in Aerospace Actuation Systems

- Material Selection: The manufacturing process of worm gear in aerospace actuation systems begins with the careful selection of high-quality materials. Typically, alloys with high strength-to-weight ratios, such as titanium or aerospace-grade aluminum, are preferred. These materials ensure the durability and reliability required in critical applications like aerospace actuators. The right material choice is essential for the performance of the worm gear for aerospace actuators, as it affects parameters like weight, strength, and resistance to environmental factors.

- Precision Machining: Following material selection, precision machining is employed to create the worm gear in flight actuation systems. Advanced CNC (Computer Numerical Control) machines are utilized to ensure accurate dimensions and tolerances. This stage is crucial, as high-precision worm gear for aerospace applications must meet stringent specifications to function effectively in demanding environments. The machining process often includes turning, milling, and grinding, which contribute to the ideal surface finish and gear profile necessary for optimal engagement and efficiency.

- Heat Treatment: After machining, the worm gear for aerospace actuators undergoes heat treatment to enhance its mechanical properties. This process involves controlled heating and cooling, which increases hardness and strength while reducing brittleness. The heat treatment is vital for the worm gear in aerospace control, ensuring that it can withstand the forces encountered during operation without failure. Different heat treatment methods like quenching and tempering may be applied depending on the material and desired characteristics.

- Surface Finishing: The final stages of manufacturing involve surface finishing techniques, which are critical for the performance and longevity of the worm gear in aerospace actuation systems. Processes such as shot peening, anodizing, or coating can be applied to improve wear resistance, reduce friction, and enhance corrosion protection. These treatments are essential for ensuring that the aerospace actuation worm gear uses meet safety and reliability standards, particularly in high-stress applications in flight actuation systems.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for the Ever-power Group in the Netherlands, and we are proud to be one of the top ten suppliers of worm gears in the country.

Our company specializes in worm gear solutions for aerospace actuation systems, ensuring high performance and reliability in critical applications. Here are some key highlights of our products:

- Top-notch quality and precision engineering, meeting stringent industry standards.

- Robust design tailored for aerospace applications, ensuring durability and efficiency.

- A strong commitment to customer service, providing personalized support and expert advice.

- Advanced manufacturing processes that guarantee consistency and performance in every product.

At RP Techniek BV, we leverage our expertise and resources to deliver exceptional worm gear solutions that meet the evolving needs of the aerospace sector.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...