The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear for Manufacturing Equipment

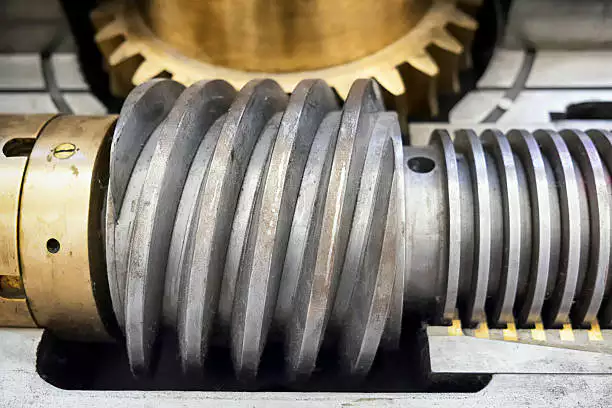

Worm gear for manufacturing equipment is a crucial component designed to transmit power and reduce speed in various applications. Often utilized in manufacturing worm gear uses, this type of gear provides high torque and precision, making it ideal for industrial worm gear for manufacturing. In factory machinery, the worm gear plays a vital role in ensuring smooth operation and efficiency. Its unique design allows for compact setups, making it an essential choice for worm gear in manufacturing machinery and production equipment.

Specifications of Worm Gear for Manufacturing Equipment

| Şartname | Details |

|---|---|

| Gear Ratio | 10:1 |

| Material | Bronze |

| Load Capacity | 5000 N |

| Efficiency | 85% |

| Operating Temperature | -20 to 100 °C |

| Lubrication Type | Grease |

Why Worm Gears are Suitable for Worm Gear for Manufacturing Equipment

- Worm gears for manufacturing equipment offer high torque transmission, making them ideal for heavy-duty applications.

- The compact design of a worm gear in manufacturing machinery allows for efficient space utilization, crucial in tight production environments.

- Manufacturing worm gear uses include conveyors and mixers, where smooth operation is essential.

- Worm gear for production equipment ensures low noise levels and minimal vibration, enhancing workplace comfort.

- Industrial worm gear for manufacturing provides excellent load capacity and durability under continuous operation.

- Worm gear in factory machinery improves reliability and reduces the need for frequent maintenance.

How Worm Gears Work in Manufacturing Equipment

Worm gears play a crucial role in manufacturing equipment, providing efficient power transmission. These gears consist of a worm, which is a screw-shaped component, and a worm wheel, allowing for high torque and compact design. In manufacturing machinery, the worm gear's ability to reduce speed while increasing torque makes it ideal for various applications. The manufacturing worm gear uses include conveyor systems and robotic arms. The worm gear for production equipment ensures smooth and precise movements, enhancing operational efficiency. Furthermore, the industrial worm gear for manufacturing is designed to withstand heavy loads and harsh conditions, making it a reliable choice for factory machinery.

Manufacturing Process of Worm Gear for Manufacturing Equipment

- Material Selection: The first step in producing a worm gear for manufacturing equipment is selecting the appropriate materials. Typically, high-strength steel or stainless steel is chosen for its durability and wear resistance. These materials are crucial for ensuring the longevity of the worm gear in manufacturing machinery. The selected material must be able to withstand the operational stress and environmental factors, which makes it suitable for various manufacturing worm gear uses.

- Design and Engineering: After material selection, the design phase begins, where engineers create detailed specifications for the worm gear for production equipment. Advanced CAD software is used to simulate the gear's performance under various conditions. This step is essential for optimizing the geometry of the worm gear to ensure maximum efficiency. Proper design also contributes to the overall effectiveness of industrial worm gear for manufacturing applications.

- Machining: The machining process involves cutting, shaping, and finishing the worm gear in factory machinery. This is achieved through various techniques like milling, turning, and grinding. Precision is key during this stage to ensure that the worm gear fits perfectly within manufacturing equipment. High-precision tools are utilized to guarantee that the dimensions and tolerances are met, resulting in a high-quality product that meets industry standards.

- Heat Treatment: Once machined, the worm gear undergoes heat treatment to enhance its mechanical properties. This process increases hardness and strength, making the worm gear more resilient to wear and tear during operation in manufacturing equipment. The heat treatment process is tailored to suit the specific requirements of the worm gear in manufacturing machinery, ensuring optimal performance under demanding conditions.

- Quality Control: The final step in the manufacturing process includes stringent quality control measures. Each worm gear is inspected for dimensional accuracy, surface finish, and overall functionality. Advanced testing methods such as non-destructive testing (NDT) may be employed to detect any potential flaws. This ensures that the industrial worm gear for manufacturing meets the required specifications and can perform reliably in production equipment.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands and is among the top ten worm gear suppliers in the country. Our commitment to providing high-quality worm gears for manufacturing equipment has established us as a trusted name in the industry.

- Top-Notch Quality: Our products are manufactured using advanced technology and premium materials, ensuring exceptional durability and performance.

- Superior Craftsmanship: Each worm gear is designed with precision, meeting the highest industry standards for reliability and efficiency.

- Strong Market Presence: With years of experience, we have built a solid reputation, serving a diverse range of industries effectively.

- Excellent Service: Our dedicated team provides comprehensive support, ensuring customer satisfaction and fostering long-term partnerships.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...