The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear for Filling Machines

The worm gear for filling machines is a specialized mechanical component designed to efficiently transfer motion and torque in filling equipment. This worm gear in filling equipment plays a crucial role in ensuring smooth operation and precise control of the filling process. With applications in packaging filling systems, the filling machine worm gear uses its unique design to manage the movement of liquids effectively. Precision worm gear for filling enhances accuracy, making it indispensable in liquid filling machines, where reliability and efficiency are paramount.

Specifications of Worm Gear for Filling Machines

| Şartname | Details |

|---|---|

| Gear Ratio | 5:1 |

| Material | Aluminum Alloy |

| Load Capacity | 500 kg |

| Efficiency | 85% |

| Operating Temperature | -20°C to 100°C |

| Lubrication Type | Synthetic Oil |

Why Worm Gears are Suitable for Worm Gear for Filling Machines

Worm gears are ideal for filling machines due to their unique design and functionality. Here are some key reasons:

- Worm gear for filling machines provides excellent torque transmission, ensuring smooth operation.

- The compact design of worm gear in filling equipment saves space, making it suitable for various setups.

- Filling machine worm gear uses allow for precise control over the filling process, enhancing accuracy.

- Worm gear for packaging filling systems is known for its durability and reliability, essential for continuous operation.

- Precision worm gear for filling ensures consistent performance in liquid filling machines, promoting efficiency.

How Worm Gears Work in Filling Machines

Worm gears play a crucial role in the operation of filling machines, providing precision and efficiency. The worm gear for filling machines is designed to convert rotational motion into linear movement, making it essential for accurate filling processes. In worm gear in filling equipment, the unique shape allows for high torque transfer with minimal backlash, ensuring that filling machine worm gear uses can be optimized for various applications. These gears are particularly effective in worm gear for packaging filling systems, where reliability is paramount. The precision worm gear for filling ensures that liquids are dispensed accurately, enhancing the performance of worm gear in liquid filling machines.

Manufacturing Process of Worm Gear for Filling Machines

- Material Selection: The first step in the manufacturing process of the worm gear for filling machines involves selecting high-quality materials. The durability and performance of the worm gear in filling equipment depend significantly on the raw materials used. Typically, strong metals like stainless steel or hardened aluminum alloys are chosen for their resistance to wear and ability to withstand high torque. Using precision worm gears for filling applications ensures that they can handle the demands of various filling processes, enhancing the efficiency of packaging filling systems.

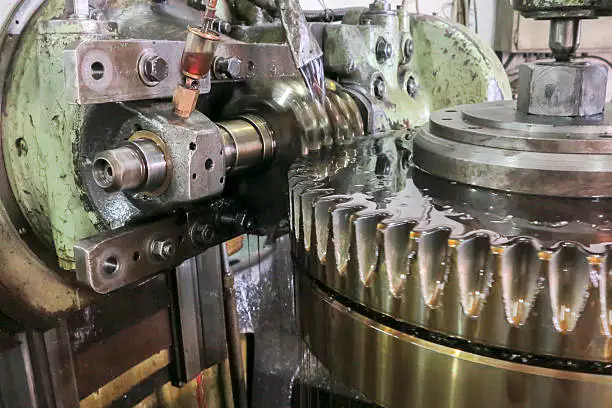

- Machining Process: Once the materials are selected, the next phase is machining. This involves cutting and shaping the raw materials into the required dimensions for the worm gear. Advanced CNC (Computer Numerical Control) machines are often used to achieve high precision in the manufacturing of the worm gear for packaging filling systems. This precision is crucial, as it affects the smooth operation of the filling machine worm gear, ensuring that the gears mesh perfectly for efficient performance in liquid filling machines.

- Heat Treatment: After machining, heat treatment is employed to enhance the mechanical properties of the worm gear for filling machines. This process involves heating the machined parts to high temperatures and then cooling them in a controlled manner. Heat treatment increases the hardness and strength of the worm gear, making it more resilient to wear and tear during operation. It is a vital step that helps in prolonging the lifespan of worm gears in filling equipment, ensuring consistent performance in packaging applications.

- Finishing Operations: The final stage of the manufacturing process includes finishing operations such as polishing and coating. These steps are essential for reducing friction and enhancing the efficiency of the worm gear in liquid filling machines. A smooth finish not only improves performance but also helps in preventing corrosion and extending the durability of the worm gear for filling machines. Additionally, these finishing touches are vital for maintaining hygiene standards in food and beverage packaging systems.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is proudly among the top ten worm gear suppliers in the Netherlands.

Our offerings include:

- High-Quality Products: We provide worm gears specifically designed for filling machines, ensuring precision and reliability in every application.

- Exceptional Standards: Our products adhere to rigorous quality standards, guaranteeing top-notch performance and durability.

- Strong Capabilities: With extensive experience in the industry, we possess the expertise to meet diverse customer needs effectively.

- Outstanding Service: Our dedicated team is committed to delivering exceptional customer service, providing support and guidance throughout the purchasing process.

Ek Bilgiler

| Edited | Zqq |

|---|

Bloglar Güncellendi

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...