In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications for H60 Mill Chain

- Material: Alloy Steel

- Pitch: 3 inches

- Diameter: 1.5 inches

- Breaking Load: 160,000 lbs

- Number of Links per 10 feet: 34

- Weight per Foot: 22.1 lbs

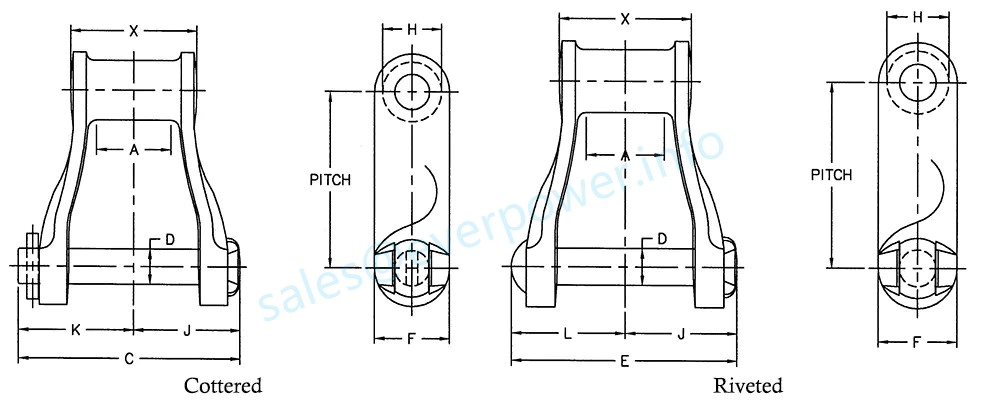

| CHAIN NO. | LINKS | PINS | PITCH IN INCHES | LINKS PER 10 FEET | WEIGHT PER FOOT LBS. | AVERAGE ULTIMATE STRENGTH LBS. | RECOMMENDED MAXIMUM WORKING LOAD LBS. | CHAIN CONSTRUCTION | AVAILABLE ATTACHMENTS | MAXIMUM ALLOWABLE SPROCKET FACE A | OVERALL WIDTH¡ª COTTERED C | DIAMETER OF PIN D | OVERALL WIDTH¡ª RIVETED E | HEIGHT OF SIDEBARS F | DIAMETER OF BARREL H | HEAD OF PIN TO CENTER LINE J | END OF PIN TO CENTER LINE¡ª COTTERED K | END OF PIN TO CENTER LINE¡ª RIVETED L | BEARING LENGTH X |

| H 60 | ALL NUMBERS A-L Primal |

ALL NUMBERS Carbon Steel, Heat-Treated | 2.308 | 52 | 2.1 | 9450 | 1560 | Riveted or Cottered | H2, K1 | 0.75 | 2.62 | 0.312 | 2.62 | 0.75 | 0.75 | 1.25 | 1.38 | 1.38 | 1.50 |

| H 74 | 2.609 | 46 | 3.0 | 13500 | 1850 | Riveted or Cottered | F4 | 1.00 | 3.12 | 0.375 | 2.88 | 1.00 | 0.88 | 1.50 | 1.62 | 1.62 | 1.66 | ||

| H 78 | 2.609 | 46 | 4.2 | 22200 | 2810 | Riveted or Cottered | A1, F4, F8, G19, H1, H2, K1, K2 | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 79 | 2.609 | 46 | 4.8 | 24300 | 2810 | Riveted or Cottered | None | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 82 | 3.075 | 39 | 5.5 | 27000 | 3580 | Riveted or Cottered | K2 | 1.25 | 3.88 | 0.562 | 3.88 | 1.25 | 1.22 | 1.88 | 2.00 | 2.00 | 2.12 | ||

| H 87 | 4.000 | 30 | 6.5 | 33750 | 4450 | Riveted or Cottered | None | 1.50 | 4.38 | 0.625 | 4.19 | 1.38 | 1.38 | 2.06 | 2.12 | 2.12 | 2.38 | ||

| H 124 | 4.000 | 30 | 8.8 | 40500 | 6180 | Riveted or Cottered | K2 | 1.62 | 4.88 | 0.750 | 4.75 | 1.56 | 1.44 | 2.25 | 2.50 | 2.50 | 2.75 |

giriiş

The H60 Mill Chain is a high-strength chain commonly used in heavy-duty applications such as lumber mills, paper mills, and grain elevators. It is known for its excellent durability and resistance to wear and tear, making it an ideal choice for applications that require a reliable and long-lasting chain.

Construction

The H60 Mill Chain is made from high-quality alloy steel that is heat-treated for maximum strength and durability. The chain consists of a series of links that are connected by pins and bushings, which allow the chain to move smoothly and efficiently. The links are designed with a unique contour that reduces stress and wear on the chain, ensuring a longer service life.

Design Features

The H60 Mill Chain has several design features that make it an ideal choice for heavy-duty applications. These features include:

- High-strength construction: The H60 Mill Chain is made from high-quality alloy steel that is heat-treated for maximum strength and durability.

- Unique contour design: The links of the chain are designed with a unique contour that reduces stress and wear, ensuring a longer service life.

- Smooth operation: The chain consists of links that are connected by pins and bushings, allowing it to move smoothly and efficiently.

- Resistance to wear and tear: The H60 Mill Chain is highly resistant to wear and tear, making it an ideal choice for heavy-duty applications.

Uygulamalar

The H60 Mill Chain is commonly used in a variety of heavy-duty applications, including:

- Lumber mills: The H60 Mill Chain is ideal for lumber mills, where it is used to move logs and lumber through the production process.

- Paper mills: The chain is also used in paper mills, where it is used to transport paper through the production process.

- Grain elevators: The H60 Mill Chain is commonly used in grain elevators, where it is used to move grain from one location to another.

- Other heavy-duty applications: The chain is also used in a variety of other heavy-duty applications, including mining, construction, and manufacturing.

Maintenance

To ensure the maximum service life of the H60 Mill Chain, it is important to perform regular maintenance. This includes regular lubrication, inspection for wear and tear, and replacement of any damaged or worn components. By following a regular maintenance schedule, the H60 Mill Chain can continue to provide reliable and efficient service for many years to come.

Conclusion

The H60 Mill Chain is a high-strength, durable chain that is commonly used in a variety of heavy-duty applications. Its unique contour design, smooth operation, and resistance to wear and tear make it an ideal choice for applications that require a reliable and long-lasting chain. By following a regular maintenance schedule, the H60 Mill Chain can provide many years of reliable and efficient service.

Choose Our Malleable Casting Chains

RP Techniek BV is the Netherlands sales agent of Ever-power Group, a leading manufacturer and supplier of power transmission products. We take pride in offering high-quality malleable cast iron chains that are suitable for a broad range of applications.

Our H60 Mill Chain is one of our most popular products. It is made of high-grade malleable iron and can withstand heavy loads and harsh operating conditions. Our malleable casting chains are unique in that they are highly flexible and can be customized to meet specific customer requirements.

We stand out from our competitors in terms of product quality, customer service, and production capabilities. We use advanced manufacturing technologies and equipment to ensure that our products meet international standards and are of consistent quality. Our team of experienced engineers and technicians is always available to provide technical support and assistance to our customers.

In addition to our malleable casting chains, we offer a wide range of other types of casting chains for sale. These include alloy steel chains, stainless steel chains, and many other varieties. Whatever your needs may be, we have the expertise and resources to meet them.

Sprockets for Sale

When it comes to H60 mill chains, finding the right sprocket is essential. At our company, we offer a wide variety of sprockets that are perfectly suited for use with H60 mill chains. Our selection includes both finished bore and bushed bore sprockets, as well as double strand sprockets and idler sprockets.

Our sprockets are crafted from high-quality materials, ensuring that they are both durable and reliable. We also offer a range of tooth counts, so you can find the perfect sprocket to match the needs of your mill chain.

Whether you're looking for a standard, off-the-shelf sprocket or need something custom-made to fit your unique requirements, we have you covered. Our experienced team can help you find the perfect sprocket for your H60 mill chain.

Browse our selection of sprockets today to find the perfect fit for your mill chain needs.

Ek Bilgiler

| Editor | Zqq |

|---|

Bloglar Güncellendi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...