Details

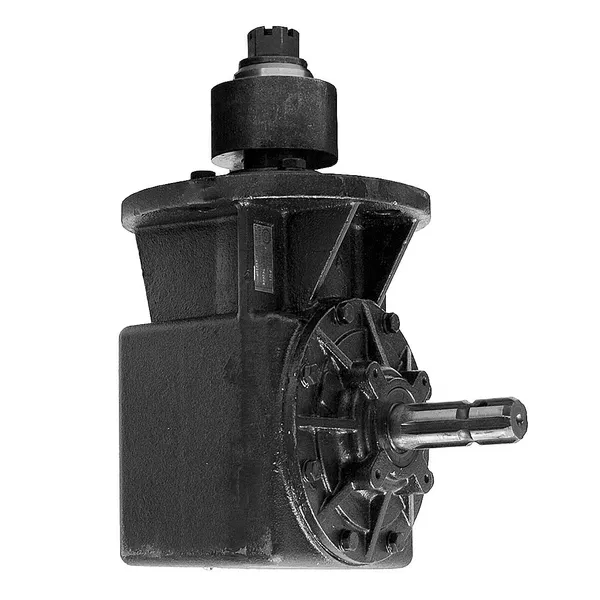

| Model | EPT-RC71 Rotary Cutter Gearbox |

| Torque | 4,083 – 9,683 lb.-in. (461 – 1,093 Nm.) |

| Ratios | 1.21:1, 1:1, 1:1.21, 1:1.46, 1:1.93 |

| Gear Type | Bevel |

| Seal Type | Triple Lip Spring Loaded |

| Bearing Type | Tapered Roller |

| Oil Capacity | 35 oz. (1.04 L) |

| Weight | 83 lbs. (37.7 kg.) |

Introduction to Rotary Cutter Gearboxes

In the world of agricultural machinery, rotary cutter gearboxes play a crucial role in ensuring efficient and effective cutting operations. These gearboxes are specifically designed to withstand the demanding conditions of heavy-duty cutting tasks, providing the necessary power and torque for smooth operation.

Understanding the Omni Code RC-71 Gearbox

The Omni Code RC-71 gearbox is a widely used model known for its reliability and durability. Featuring advanced engineering and precision manufacturing, this gearbox offers exceptional performance for rotary cutters. Its compact design and high torque capacity make it a popular choice among farmers and landscapers.

Key Features of the RC-71 Gearbox

The RC-71 gearbox boasts several features that set it apart from other models on the market:

- High torque capacity for heavy-duty cutting tasks

- Compact and space-saving design

- Precision gears for smooth and efficient operation

- Durable construction to withstand harsh conditions

- Easy maintenance and serviceability

Benefits of Upgrading to the RC-71 Gearbox

By replacing your existing gearbox with the Omni Code RC-71, you can enjoy numerous benefits:

- Improved cutting efficiency and performance

- Reduced downtime due to its robust construction

- Enhanced durability for long-term reliability

- Cost-effective solution for your cutting needs

- Compatibility with various rotary cutter models

Installation Process and Tips

Installing the RC-71 gearbox is a straightforward process, but it's essential to follow these steps for optimal results:

- Ensure the power source is disconnected before beginning the installation.

- Remove the old gearbox carefully, making sure to keep track of any necessary components.

- Clean the mounting area and inspect for any damage or wear.

- Attach the RC-71 gearbox firmly, following the manufacturer's guidelines.

- Reconnect the power source and test the gearbox for proper functionality.

For additional assistance or troubleshooting, consult the product manual or contact our technical support team.

The Rotary Cutter Gearboxes, specifically the Omni Code RC-71 Gearbox, offer a reliable and efficient solution for your cutting needs. With its advanced features, durability, and easy installation process, this gearbox is a top choice for professionals in the agriculture and landscaping industries. Upgrade to the RC-71 gearbox today and experience the difference in performance and reliability.

Why Choose Our Agricultural Gearboxes?

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. With our expertise and experience, we are proud to offer top-quality agricultural gearboxes to meet your needs. Our commitment to excellence sets us apart from the competition.

One of our exceptional products is the Rotary Cutter Gearboxes – Replacement of Omni Code RC-71 Gearbox. These gearboxes are designed to deliver superior performance and durability, ensuring optimal functioning of your machinery. We prioritize product quality and reliability to provide you with gearboxes that will withstand the toughest agricultural applications.

But our dedication to customer satisfaction doesn't end with our products. At RP Techniek BV, we strive to offer exceptional service. Our knowledgeable team is always ready to assist you in finding the right gearbox for your specific requirements. We provide prompt responses, technical support, and efficient after-sales service to ensure your complete satisfaction.

In addition to agricultural gearboxes, we also offer a wide range of other farm machinery parts and transmission components. With our extensive inventory, you can find everything you need to keep your agricultural equipment running smoothly.

Choose RP Techniek BV for reliable agricultural gearboxes and exceptional customer service. Contact us today to discuss your needs and experience the difference of working with a trusted partner in the industry.

PTO Shafts for Agricultural Gearboxes

When it comes to the relationship between PTO shafts and agricultural gearboxes, it is crucial to understand their interdependence. PTO shafts, or power take-off shafts, play a vital role in transferring power from the tractor to the agricultural gearbox. These shafts transmit the rotational energy, allowing the gearbox to harness that power for various agricultural applications.

At our company, we recognize the significance of reliable and efficient PTO shafts for agricultural gearboxes. That is why we offer a wide range of high-quality PTO shafts specifically designed for agricultural use. Our PTO shafts are carefully crafted to withstand the demanding conditions of the agricultural industry, ensuring optimal performance and longevity.

With our extensive selection of PTO shafts, customers can find the perfect fit for their specific agricultural gearbox requirements. Whether it's for replacing a worn-out shaft or upgrading to a more robust option, our PTO shafts provide the reliability and durability needed for seamless power transfer.