Wstęp

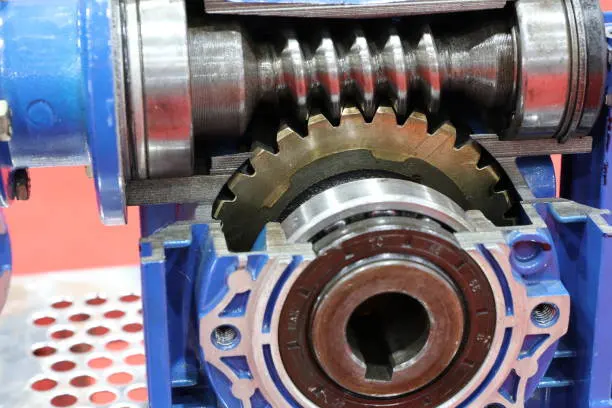

In this article, we will explore the various factors that influence the selection of lubricants for EPRV Series Small Worm Gearboxes. Lubricants play a crucial role in ensuring the smooth operation and longevity of these gearboxes. By understanding the key factors that impact lubricant selection, users can make informed decisions and optimize the performance of their gearboxes. Let's dive in!

1. Operating Temperature

The operating temperature of a gearbox is a critical factor to consider when selecting lubricants. Different lubricants have varying temperature ranges at which they perform optimally. It is essential to choose a lubricant that can withstand the specific operating temperature of the EPRV Series Small Worm Gearbox to ensure proper lubrication and prevent overheating.

2. Load Capacity

The load capacity of the gearbox is another crucial factor to consider when selecting lubricants. The lubricant should have excellent load-carrying properties to support the gearbox under different operating conditions. High-quality lubricants with extreme pressure additives can provide superior protection against wear and extend the gearbox's service life.

3. Speed Requirements

The speed at which the gearbox operates influences the selection of lubricants. Higher speeds require lubricants with excellent thermal stability and viscosity characteristics to maintain proper lubrication. Choosing the right lubricant ensures smooth and efficient gearbox operation, reducing the risk of premature failure.

4. Environmental Conditions

The environmental conditions in which the gearbox operates also impact lubricant selection. Factors such as humidity, dust, and contaminants can affect the lubricant's performance. It is crucial to select lubricants that provide effective protection against corrosion, oxidation, and contamination to maintain optimal gearbox performance.

5. Compatibility with Materials

Compatibility between the lubricant and the gearbox's materials is essential for long-term performance. Different gear materials and seals may require specific lubricants to ensure compatibility and prevent degradation or damage. It is crucial to consult the gearbox manufacturer's recommendations and select lubricants that are compatible with the gearbox's materials.

6. Maintenance Considerations

Maintenance requirements should also be taken into account when selecting lubricants. Some lubricants may require more frequent inspection and replacement, while others offer extended service intervals. Understanding the maintenance needs of the gearbox and selecting lubricants accordingly can help optimize maintenance schedules and reduce downtime.

7. Environmental Impact

Considering the environmental impact of lubricants is increasingly important in today's eco-conscious world. Choosing lubricants that are biodegradable, environmentally friendly, and comply with industry regulations can help minimize the gearbox's ecological footprint and contribute to sustainable practices.

8. Cost-effectiveness

While performance and quality are essential, cost-effectiveness is also a factor to consider. Balancing the upfront cost of the lubricant with its long-term benefits and performance can help optimize overall cost-effectiveness. It is crucial to evaluate the lubricant's lifespan, performance characteristics, and maintenance requirements when assessing its cost-effectiveness.

Conclusion

Choosing the right lubricant for EPRV Series Small Worm Gearboxes is crucial for maximizing performance, ensuring longevity, and minimizing downtime. By considering factors such as operating temperature, load capacity, speed requirements, environmental conditions, material compatibility, maintenance considerations, environmental impact, and cost-effectiveness, users can make informed decisions and select the most suitable lubricants for their gearboxes. Explore our website and contact us to purchase our high-quality lubricants for EPRV Series Small Worm Gearboxes.

Silniki elektryczne na sprzedaż

The relationship between gearboxes and electric motors is symbiotic and crucial. Gearboxes, such as the EPRV Series Small Worm Gearbox, transmit power from the motor to various mechanical systems, providing torque and speed reduction. Without gearboxes, the efficient transfer of power and control of rotational motion would be challenging to achieve.

At our company, we not only provide high-quality gearboxes but also offer compatible electric motors for sale. Our electric motors are designed to work seamlessly with our gearboxes, ensuring optimal performance and compatibility. We understand the importance of a well-matched motor and gearbox system in achieving efficient operation and maximizing productivity.

O nas

RP Techniek BV is the Netherlands sales agent of the Ever-power Group. As a comprehensive transmission equipment manufacturer, we specialize in the research, development, manufacturing, and sales of speed reducers. With over 25 years of experience, we have earned a reputation for delivering the highest quality gearboxes to customers in Europe, America, Africa, Asia, and beyond.

Our company prides itself on its manufacturing capabilities, serving a diverse range of industries with the utmost dedication to quality, service, and competitive pricing. We continually invest in advanced production and testing equipment, employing industry professionals and technicians who drive innovation in research, development, and manufacturing.

Our gearboxes find applications across various industries, including equipment, food, car washing, packaging, transmission, automation, and solar energy. The superior performance and reliability of our gearboxes have earned the trust and satisfaction of our customers.

Edited by: Zqq

Pytania i odpowiedzi

Q: What is the recommended operating temperature range for EPRV Series Small Worm Gearboxes?

A: The recommended operating temperature range for EPRV Series Small Worm Gearboxes is -10¡ãC to 80¡ãC.

Q: Do I need to use a specific lubricant for EPRV Series Small Worm Gearboxes at high speeds?

A: Yes, it is crucial to choose a lubricant with excellent thermal stability and viscosity characteristics to maintain proper lubrication at high speeds.

Q: Are your lubricants environmentally friendly and biodegradable?

A: Yes, our lubricants are formulated to be environmentally friendly and biodegradable, minimizing their ecological impact.

Q: Can I use the same lubricant for different gear materials?

A: It is recommended to consult the gearbox manufacturer's recommendations and select lubricants that are compatible with the specific gear materials to ensure optimal performance.

Q: How often should I inspect and replace the lubricant in EPRV Series Small Worm Gearboxes?

A: The frequency of lubricant inspection and replacement depends on factors such as operating conditions and maintenance schedules. It is essential to follow the manufacturer's guidelines for optimal performance and longevity.

Edited by: Zqq