In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Winch Planetary Gearbox for Off-Road Vehicle Winches

The Winch Planetary Gearbox for Off-Road Vehicle Winches is an essential component designed to enhance the performance of winches used in rugged terrains. This gearbox employs a planetary gear system, providing superior torque and efficient power transfer. Ideal for off-road vehicles, it enables smooth and reliable operation during recovery tasks, ensuring that drivers can tackle challenging landscapes with confidence. Durable and robust, it stands up to the demands of adventurous expeditions.

Features and Specifications of Winch Planetary Gearbox for Off-Road Vehicle Winches

| Specification | Details |

|---|---|

| Output torque range | 1000-280000 N.m |

| Gear ratios | i=5.3-400 |

| Support | The gearbox has rotating housing flanges to fit winch |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve on request |

| Łożysko | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake on request |

| Performance figures | Refer to FEM standards, class M5 (T5-L2) for output max. speeds of 25 rpm |

| Compatibility | Technical data and installation dimensions of the EP400W Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 800 Series, so these three can be used interchangeably |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP400W1 | 870 | 6.09 | 1000 | 130 |

| EP401W1 | 1300 | 6.2 | 1000 | 270 |

| EP402W2 | 4000 | 12.4-37.1 | 3500 | - |

| EP403W2 | 4000 | 15.4-40 | 3500 | 270 |

| EP405W | 7000 | 20-80 | 3500 | 270 |

| EP405.4W | 5500 | 26-57 | 3500 | 280 |

| EP406AW | 12500 | 23-220 | 3500 | 430 |

| EP406W | 13000 | 28-140 | 3500 | 430 |

| EP406BW3 | 17500 | 63-136 | 3500 | 430 |

| EP407AW | 18000 | 38-136 | 3500 | 430-530 |

| EP407W3 | 26000 | 63-136 | 3500 | 530 |

| EP410W3 | 37500 | 62-177 | 3500 | 530 |

| EP413W3 | 42500 | 86-172 | 3500 | 610 |

| EP414W3 | 67000 | 76-186 | 3500 | 1200 |

| EP415W3 | 100000 | 81-215 | 3000 | 1200 |

| EP416W3 | 140000 | 87-255 | 3000 | 2000 |

| EP417W3 | 200000 | 123-365 | 3000 | 2000 |

| EP419W3 | 275000 | 161-306 | 2500 | 3000 |

Winch Planetary Gearbox for Off-Road Vehicle Winches - Working Principle

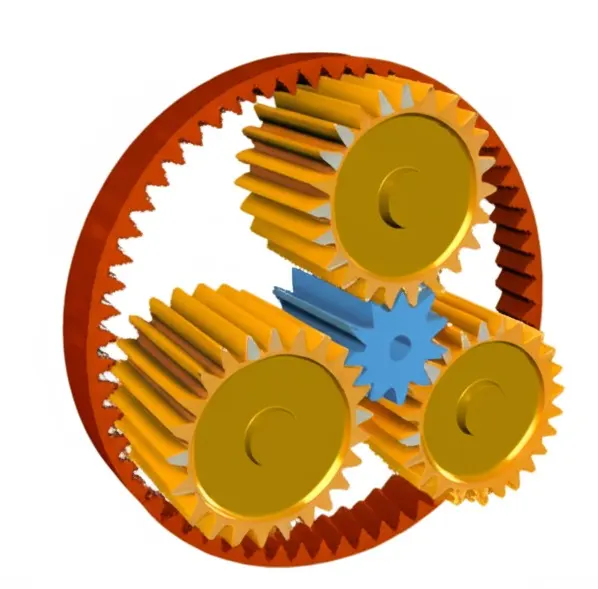

The Winch Planetary Gearbox operates on a simple yet effective principle. It consists of a sun gear, planet gears, and a ring gear, which work together to provide high torque and reduced speed. When the winch is engaged, the motor drives the sun gear, causing the planet gears to rotate around it while also rotating within the ring gear. This unique arrangement allows for smooth and efficient power transfer, making it ideal for off-road applications where high pulling force is required. The compact design ensures durability and reliability in challenging terrains.

Advantages of Winch Planetary Gearbox for Off-Road Vehicle Winches

- High Torque and Load Capacity: The multi-tooth meshing design effectively distributes loads, enhancing the gearbox's capacity to handle high torque demands.

- Compactness and Space Efficiency: Compared to traditional gearboxes, our planetary gearbox offers a significant volume advantage, making it easier to fit in tight spaces.

- Transmission Efficiency: Achieving an efficiency of 97%-98% in single-stage configurations, our multi-stage setups further optimize performance.

- Durability and Reliability: The uniform stress distribution extends operational life, ensuring the gearbox withstands rigorous off-road conditions.

- Customizability: Tailored to specific winching needs, we can adjust gear ratios, torque, and mounting options for optimal performance.

Selection Guide for Winch Planetary Gearbox

When selecting a winch planetary gearbox for off-road vehicle winches, consider the following factors: power or torque requirements, gear ratio, and speed. Assess the input and output types, including spline, hollow, or solid options. Evaluate if external forces or radial loads impact the input or output ends. Additionally, factor in operating temperature, lifespan expectations, and any special needs such as continuous operation or shock loading. These considerations ensure optimal performance and reliability.

How to Reduce Operating Noise of Winch Planetary Gearbox?

To minimize operating noise in winch planetary gearboxes for off-road vehicles, precision machining and gear design play crucial roles. High-quality materials and advanced manufacturing techniques ensure that gears mesh smoothly, reducing friction and vibration. Additionally, optimizing gear tooth profiles and employing noise-dampening materials can significantly lower sound levels during operation. Regular maintenance and lubrication also contribute to quieter performance by preventing wear and ensuring efficient gear engagement.

Key Points for Noise Reduction

- Utilize precision machining for better gear alignment.

- Optimize gear tooth shapes to minimize noise.

- Incorporate noise-dampening materials in design.

- Maintain lubrication to ensure smooth operation.

Winch Planetary Gearbox Manufacturer

RP Techniek is the Dutch sales agent for Ever-power Group, specializing in high-quality gear solutions. The winch planetary gearbox plays a crucial role in the operation of off-road vehicle winches, ensuring optimal performance and reliability in demanding environments. This advanced gearbox design offers improved torque and control, making it essential for off-road applications. We invite all customers to explore our customizable solutions and invest in a winch planetary gearbox that meets your specific needs. Don't miss the opportunity to enhance your equipment with our innovative products.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...