In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications of MC56SS MC Series Stainless Steel Hollow Pin Chain

- Material: Stainless Steel

- Chain Type: Hollow Pin

- Series: MC

- Pitch Size: 3/4 inch

- Minimum Tensile Strength: 11650 lbs

- Weight per Foot: 2.5 lbs

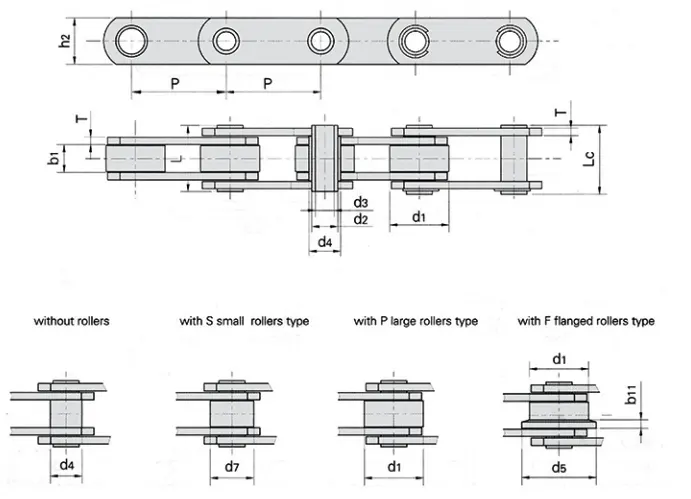

| Chain No. | Poziom | Roller diameter |

Bush diameter |

Plate depth |

width between inner plates |

pin diameter | pin length |

Plate thickness |

Breaking load |

Breaking load |

||||||||||

| P(mm) | P(mm) | P(mm) | P(mm) | P(mm) | P(mm) | d1 max (mm) |

d7 max (mm) |

d5 max (mm) |

b11 (mm) |

d4 max (mm) |

h2 max (mm) |

b1 min (mm) |

d2 min (mm) |

d3 min (mm) |

L max (mm) |

Lc max (mm) |

T max (mm) |

Q min (KN/LB) |

*Q min (KN/LB) |

|

| MC28SS | 63 | 80 | 100 | 125 | 160 | 36 | 25 | 45 | 4.5 | 17.5 | 25 | 20 | 13 | 8.2 | 36 | 38.5 | 3.5 | 19.6/4454.8 | 28/6363.7 | |

| MC56SS | 80 | 100 | 125 | 160 | 200 | 250 | 50 | 30 | 60 | 5 | 21 | 35 | 24 | 15.5 | 10.2 | 45 | 47.5 | 4 | 39.2/8908.9 | 63/14317.8 |

| MC112SS | 100 | 125 | 160 | 200 | 250 | 315 | 70 | 42 | 85 | 7 | 29 | 50 | 32 | 22 | 14.3 | 62.5 | 64.3 | 6 | 78.4/17817.8 | 126/28635.6 |

| MC224SS | 160 | 200 | 250 | 315 | 400 | 500 | 100 | 60 | 120 | 10 | 41 | 70 | 43 | 31 | 20.3 | 83 | 85.5 | 8 | 156.8/35636.3 | 245/55680.8 |

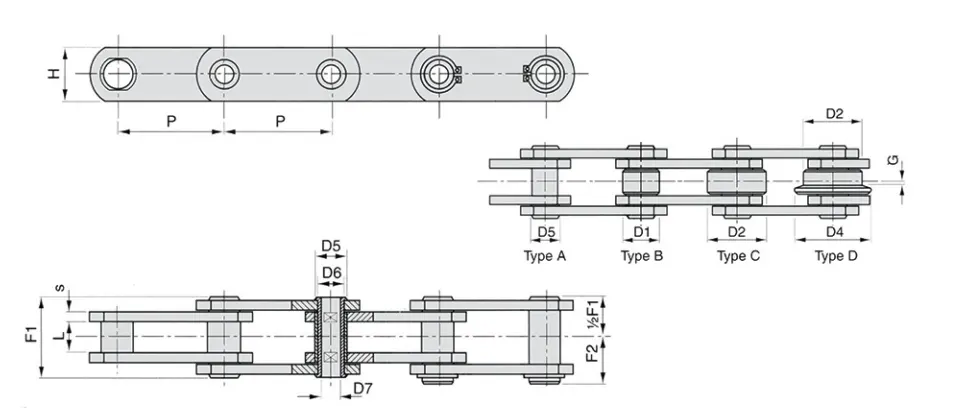

| Chain No. |

P | L | D1 | D2 | D4 | G | D5 | D6 | D7 | H | S | F1 | F2 | Breaking (load kN) |

Masa Type C (kg/m) |

| MC28SS | 50 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 4.3 |

| MC28SS | 63 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 3.8 |

| MC28SS | 80 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 3.2 |

| MC28SS | 100 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 2.8 |

| MC28SS | 125 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 2.5 |

| MC56SS | 63 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 8.5 |

| MC56SS | 80 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 7.2 |

| MC56SS | 100 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 6.2 |

| MC56SS | 125 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 5.4 |

| MC56SS | 160 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 4.7 |

| MC112SS | 80 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 16.6 |

| MC112SS | 100 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 14 |

| MC112SS | 125 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 11.2 |

| MC112SS | 160 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 10.2 |

| MC112SS | 200 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 8.9 |

| MC112SS | 250 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 156.8 | 7.9 |

| MC224SS | 125 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 32.3 |

| MC224SS | 160 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 27.1 |

| MC224SS | 200 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 23.5 |

| MC224SS | 250 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 20.6 |

| MC224SS | 315 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 17.2 |

MC56SS MC Series Stainless Steel Hollow Pin Chain

Wstęp

MC56SS MC Series Stainless Steel Hollow Pin Chain is an innovative chain that is designed to meet the demands of various industries. It is made of high-quality materials that are resistant to wear and tear, corrosion, and extreme temperatures. This chain is used in various applications, including food processing, packaging, and manufacturing.

Cechy

Stainless Steel Construction

The MC56SS MC Series Stainless Steel Hollow Pin Chain is made of high-grade stainless steel, which makes it resistant to corrosion and rust. This feature makes it ideal for use in challenging environments, such as those found in the food processing industry.

Hollow Pins

The chain features hollow pins that reduce its weight, making it easier to install and maintain. The hollow pins help to reduce the overall weight of the chain, making it ideal for use in applications where weight is a critical factor.

High Strength

The MC56SS MC Series Stainless Steel Hollow Pin Chain is designed to withstand high loads and stresses. It is engineered to provide maximum strength and durability, ensuring that it can withstand the rigors of heavy-duty applications.

Wide Temperature Range

This chain is designed to operate within a wide range of temperatures, making it suitable for use in extreme environments. It can operate in temperatures ranging from -40¡ãF to 752¡ãF (-40¡ãC to 400¡ãC).

Self-Lubricating

The chain is designed to be self-lubricating, reducing the need for frequent maintenance. This feature reduces downtime and increases productivity, making it ideal for use in applications where reliability and efficiency are critical.

Applications

Food Processing

The MC56SS MC Series Stainless Steel Hollow Pin Chain is ideal for use in the food processing industry. It is resistant to corrosion, making it suitable for use in harsh environments where food safety is critical. It is also self-lubricating, reducing the need for frequent maintenance.

Manufacturing

This chain is used in manufacturing applications that require high strength and durability. It is designed to withstand heavy loads and stresses, making it ideal for use in conveyor systems and other industrial applications.

Opakowanie

The MC56SS MC Series Stainless Steel Hollow Pin Chain is also used in packaging applications. Its high strength and durability make it suitable for use in packaging equipment that requires heavy loads and stresses.

Conclusion

The MC56SS MC Series Stainless Steel Hollow Pin Chain is a reliable and versatile chain that is designed to meet the demands of various industries. Its high-quality construction, wide temperature range, and self-lubricating feature make it an ideal choice for applications where reliability and efficiency are critical. Whether you are in the food processing, manufacturing, or packaging industry, this chain is sure to meet your needs and exceed your expectations.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agent for Ever-power Group in the Netherlands. Our company provides a wide range of stainless steel roller chains for different applications, including the MC56SS MC Series Stainless Steel Hollow Pin Chain.

Our chains are manufactured with the highest quality materials to ensure long-lasting performance. The stainless steel construction offers excellent corrosion resistance, making them suitable for use in harsh environments. Moreover, our chains undergo rigorous testing procedures to ensure that they meet international standards.

At RP Techniek BV, we prioritize customer satisfaction and strive to provide the best service possible. Our team of experts is always available to assist with product selection, technical support, and after-sales service. We are committed to meeting the needs of our customers and providing them with reliable solutions.

In addition to the MC56SS MC Series Stainless Steel Hollow Pin Chain, we offer a variety of other types of stainless steel roller chains for sale. Customers can choose from a range of sizes and specifications to suit their specific needs.

Please see the attached image to learn more about our manufacturing capabilities.

Sprockets for Sale

When it comes to finding the right chain sprocket to pair with your MC56SS MC Series Stainless Steel Hollow Pin Chain, look no further than our selection of sprockets for sale. At our company, we offer a wide variety of sprockets to meet your specific needs, whether you require a standard size or a custom design.

Our sprockets are made from high-quality materials, ensuring durability and longevity in even the toughest operating conditions. They are precision-machined to meet exacting standards, and are available in a range of tooth counts and configurations to ensure proper fit and function with your chain.

Whether you need a sprocket for industrial equipment, agricultural machinery, or anything in between, we have the perfect solution for you. We pride ourselves on offering exceptional customer service and competitive pricing, and we are committed to helping you find the right sprocket to meet your needs.

So if you are in the market for a new sprocket, look no further than our selection of high-quality sprockets for sale. Contact us today to learn more about our products and services, and to place your order.

Informacje dodatkowe

| Editor | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...