In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Inverted Tooth Silent Chains

At RP Techniek BV, a proud branch of Ever-power Netherlands, we specialize in providing high-quality inverted tooth silent chains that cater to a variety of industrial applications. Our chains are designed for efficiency, durability, and silent operation, making them ideal for environments where noise reduction is crucial.

Inverted tooth silent chains are a type of power transmission chain known for their smooth operation and reduced noise levels. Unlike traditional chains, these silent chains feature specially designed teeth that engage with sprockets, providing a stable and quiet performance. They are widely used in machinery where precision and reliability are essential.

Flank Contact Silent Chains SC3 SC4 SC5 SC6 SC8 SC10

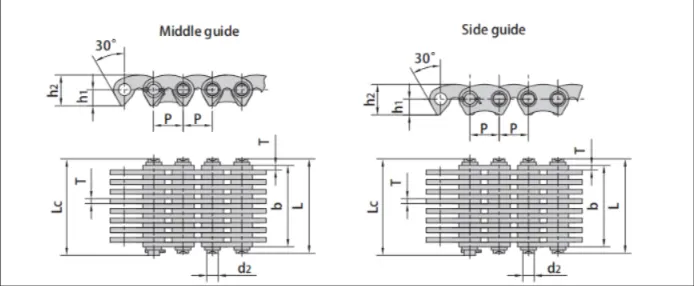

| Chain No. |

Poziom | Chain width |

Pin diameter |

Pin length |

Distance from hole center to tooth |

Plate depth |

Plate thickness |

Guide type |

Number of plates |

Ultimate tensile strength |

Average tensile strength |

Waga per meter |

|

| P | b min |

d2 max |

L max |

Lc max |

h₁ | h2 max |

T max |

n | Q min |

Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | |||

| SC3 | 9.525 | 13.5 16.5 19.5 22.5 28.5 |

3.95 | 18.5 21.5 24.5 27.5 33.5 |

20.0 23.0 26.0 29.0 35.0 |

5.3 | 10.0 | 1.5 | Outside Outside Outside Outside Inside |

9 11 13 15 19 |

10.0/2272 12.5/2840 15.0/3409 17.5/3997 22.5/5114 |

11.2 14.0 16.8 19.6 25.2 |

0.60

0.73 |

| SC4 | 12.700 | 19.5 22.5 25.5 28.5 34.5 40.5 46.5 52.5 |

5.08 | 24.5 27.5 30.5 33.5 39.5 45.5 51.5 57.5 |

26.0

29.0 |

7.0 | 13.4 | 1.5 | Outside Outside Outside Inside Inside Inside Inside Inside |

13 15 17 19 23 27 31 35 |

23.4/5318 27.4/6227 31.3/7114 35.2/8000 43.0/9772 50.8/11364 58.6/13318 66.4/15091 |

26.2 30.6 35.0 39.4 48.1 56.8 65.6 74.3 |

1.15 1.33 1.50 1.68 2.04 2.39 2.74 3.10 |

| SC5 | 15.875 | 30.0 38.0 46.0 54.0 62.0 |

5.92 | 37.0 45.0 53.0 61.0 69.0 |

38.2 46.2 54.2 62.4 70.4 |

8.7 | 16.7 | 2.0 | Inside Inside Inside Inside Inside |

15 19 23 27 31 |

45.6/10364 58.6/13318 71.7/16295 84.7/19250 97.7/22204 |

50.6 65.0 79.5 94.0 108.4 |

2.21 2.80 3.39 3.99 4.58 |

| SC6 | 19.050 | 38.0 46.0 54.0 62.0 70.0 |

6.90 | 45.0 53.0 61.0 69.0 77.0 |

46.5 54.5 62.8 70.8 78.8 |

10.5 | 20.0 | 2.0 | Inside Inside Inside Inside Inside |

19 23 27 31 35 |

70.0/15909 86.0/19545 102.0/23182 117.0/26591 133.0/30227 |

77.6 95.4 113.2 129.8 147.6 |

3.37 4.08 4.78 5.50 6.20 |

| SC8 | 25.400 | 45.0 51.0 57.0 69.0 81.0 93.0 |

8.90 | 52.0 58.0 64.0 76.2 88.2 100.2 |

53.5 59.5 65.5 77.7 89.7 101.7 |

14.0 | 26.7 | 3.0 | Inside Inside Inside Inside Inside Inside |

15 17 19 23 27 31 |

111.0/25227 125.0/28409 141.0/32045 172.0/39091 203.0/46163 235.0/53409 |

123.2 138.7 156.5 190.9225.3 260.8 |

5.31 6.02 6.37 8.15 9.57 10.98 |

| SC10 | 31.750 | 57.0 69.0 81.0 93.0 105.0 117.0 |

10.84 | 66.6

78.6 114.6 |

69.6 81.6 93.6 105.6 117.6 129.6 |

17.5 | 33.4 | 3.0 | Inside Inside Inside Inside Inside Inside |

19 23 27 31 35 39 |

165.0/37500 201.0/45681 237.0/53863 273.0/62045 310.0/70454 346.0/78636 |

183.1 223.1 263.2 303.0 341.0 380.6 |

8.42 10.19 11.96 13.73 15.50 17.27 |

Crotch Contact Silent Chains C4 Series

| Chain No. | Poziom | Chain width |

Pin diameter |

Pin length |

Distance from hole center to tooth |

Plate depth |

Plate thickness |

Guide type |

Number of plates |

Ultimate tensile strength |

Average tensile strength |

Waga

per |

|

| Pmm | h min |

d2 max |

L max |

Lc max |

h₁ | h2 max |

T max |

n | Q min |

Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | ||||

| C4-120 | 12.7 | 19.5 | 5.08 | 24.5 | 26.0 | 6.62 | 12.1 | 1.5 | Inside | 13 | 20.0/4545 | 22.2 | 1.20 |

| C4-123 | 22.5 | 27.5 | 29.0 | Inside | 15 | 23.0/5227 | 25.5 | 1.37 | |||||

| C4-129 | 28.5 | 33.5 | 35.0 | Inside | 19 | 28.5/6477 | 31.6 | 1.72 | |||||

| C4-132 | 31.5 | 36.5 | 38.0 | Inside | 21 | 31.5/7159 | 34.9 | 1.89 | |||||

| C4-138 | 37.5 | 42.5 | 44.0 | Inside | 25 | 38.0/8636 | 42.1 | 2.22 | |||||

| C4-150 | 49.5 | 54.5 | 56.0 | Inside | 33 | 50.0/11363 | 55.5 | 2.90 | |||||

| C4-320 | 12.7 | 19.5 | 5.08 | 24.5 | 26.0 | 6.62 | 12.1 | 1.5 | Outside | 13 | 20.0/4545 | 22.2 | 1.21 |

| C4-323 | 22.5 | 27.5 | 29.0 | Outside | 15 | 23.0/5227 | 25.5 | 1.38 | |||||

| C4-329 | 28.5 | 33.5 | 35.0 | Outside | 19 | 28.5/6477 | 31.6 | 1.73 | |||||

| C4-332 | 31.5 | 36.5 | 38.0 | Outside | 21 | 31.5/7159 | 34.9 | 1.90 | |||||

| C4-338 | 37.5 | 42.5 | 44.0 | Outside | 25 | 38.0/8636 | 42.1 | 2.23 | |||||

Key Features of Our Inverted Tooth Silent Chains

- Noise Reduction: Engineered to minimize operational noise, perfect for applications in sound-sensitive environments.

- Durability: Made from high-quality materials, our chains are built to withstand wear and tear, ensuring long-lasting performance.

- Efficiency: Designed for optimal power transmission, our chains reduce energy loss, making them an eco-friendly choice.

- Versatility: Suitable for various applications, including packaging machinery, conveyors, and textile machinery.

Applications of Inverted Tooth Chains

Our inverted tooth silent chains are designed to meet the demands of various industries, providing reliable performance in a range of applications. Here are some key sectors where our chains excel:

- Food Processing:

- Conveyor Systems: In food processing plants, hygiene and noise control are crucial. Our silent chains minimize noise during operation, creating a more pleasant working environment. They are also designed for easy cleaning and maintenance, ensuring compliance with food safety standards.

- Packaging Lines: Silent chains are ideal for packaging machinery, where smooth operation and precision are essential for maintaining production speed and efficiency.

- Textile Manufacturing:

- Weaving and Knitting Machines: In textile production, silent chains provide quiet operation, which is vital in large manufacturing facilities. They enable precise control over the movement of materials, reducing the risk of jams and enhancing overall productivity.

- Dyeing and Finishing Equipment: Our chains can also be used in dyeing and finishing processes, where consistent movement and reduced noise contribute to a better working atmosphere.

- Packaging Industry:

- Automated Systems: In automated packaging systems, inverted tooth silent chains ensure smooth and reliable operation. Their design helps reduce vibrations and wear on machinery, extending the lifespan of both the chains and the equipment.

- Labeling and Filling Machines: Silent chains are well-suited for labeling and filling operations, where precision and speed are critical. Their quiet operation helps maintain focus on the production line, improving overall efficiency.

- Automotive Industry:

- Assembly Lines: In automotive assembly, where multiple components are processed simultaneously, silent chains offer the quiet performance needed to reduce distractions and enhance worker focus.

- Conveyor Systems: Our chains are also utilized in conveyor systems that transport vehicle parts, ensuring smooth and reliable operation under heavy loads.

- Material Handling:

- Warehouse Automation: In automated warehouses, inverted tooth silent chains facilitate the movement of goods without the disruptive noise associated with traditional conveyor systems. This allows for a more efficient and quieter working environment.

- Forklifts and Pallet Jacks: Silent chains can be found in the drive mechanisms of various material handling equipment, providing a dependable power source while minimizing operational noise.

- Printing Industry:

- Printing Presses: Our silent chains ensure that printing presses operate smoothly and quietly, enhancing the overall quality of printed materials. Their reliable performance helps prevent disruptions in the printing process.

- Pharmaceutical Industry:

- Production Lines: In pharmaceutical manufacturing, where precision and compliance are critical, inverted tooth silent chains support efficient and quiet operation. They help ensure that production processes run smoothly, reducing the risk of contamination.

Why Choose RP Techniek BV?

- Expertise: With years of experience in the industry, our team provides expert guidance and support for all your needs.

- Customization: We understand that every application is unique. Our chains can be customized to meet your specific requirements.

- Quality Assurance: We adhere to the highest quality standards to ensure that our products meet and exceed industry expectations.

Get in Touch

Ready to enhance your machinery with our inverted tooth silent chains? Contact us today to discuss your needs and request a quote. Our dedicated team is here to assist you with any inquiries you may have.

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...