In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

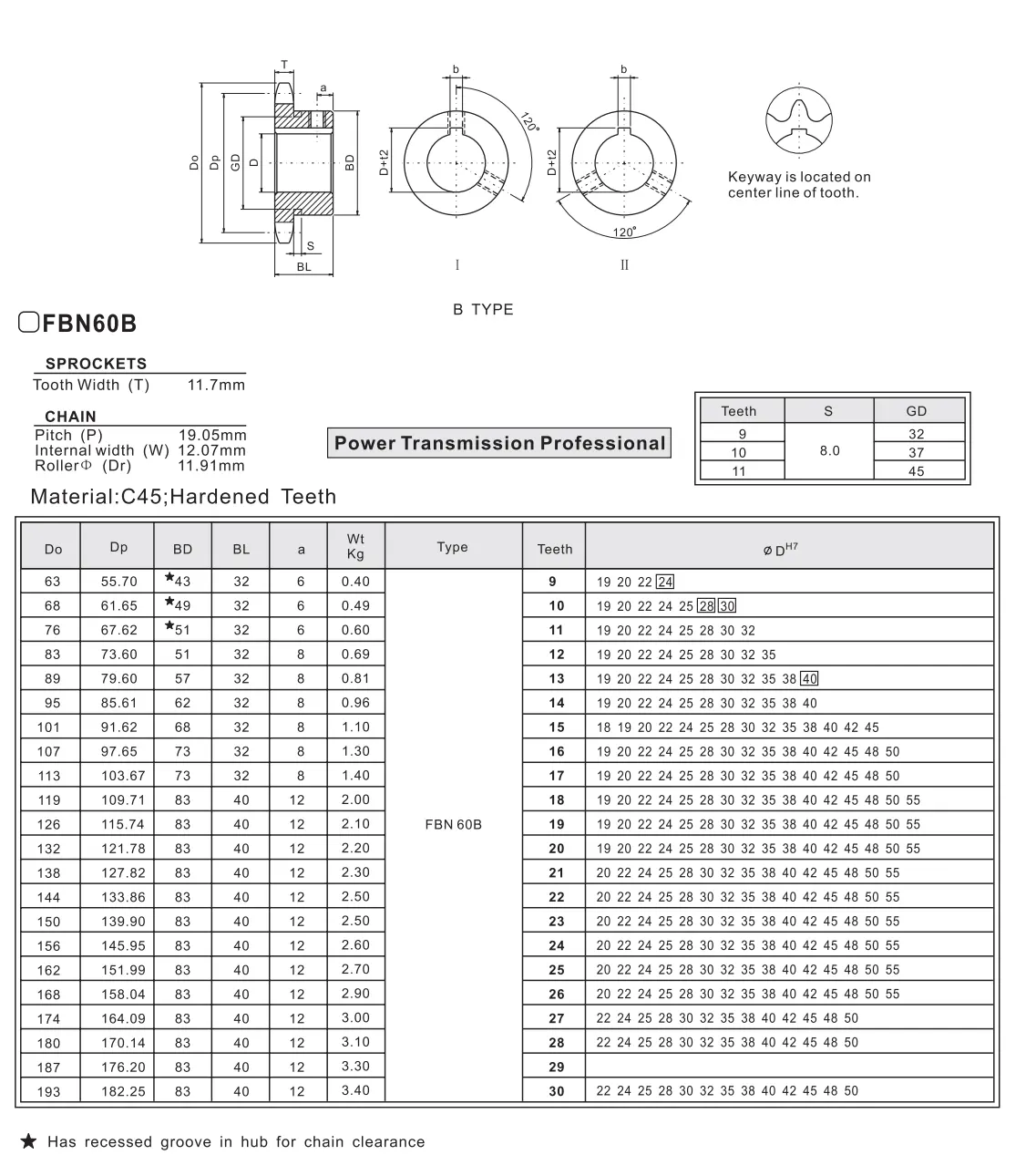

FBN60B Finished Bore Sprocket

The FBN60B Finished Bore Sprocket is engineered for optimal performance in various machinery applications. Its precision design ensures a secure fit and reliable operation, minimizing wear and extending the lifespan of your equipment. Made from high-quality materials, this sprocket delivers durability and strength, making it an essential component for efficient power transmission.

Specifications of FBN60B Asian Standard Finished Bore Sprocket

A finished bore sprocket serves a crucial role in various mechanical systems. It is characterized by a pre-bored hole that simplifies the installation process onto a shaft. The FBN60B Asian Standard sprocket, in particular, is recognized for its dependable performance and seamless compatibility with systems adhering to Asian standards, making it a preferred choice in many applications.

Materials and Manufacturing Process

The materials utilized for crafting the finished bore sprocket typically include high carbon steel, alloy steel, or stainless steel, each chosen for its strength and performance attributes. The manufacturing process is comprehensive and includes several critical steps: selecting the right materials, cutting them to specifications, stamping, forging, machining processes such as turning, milling, and drilling, followed by heat treatment techniques like quenching and tempering to enhance durability. Surface treatment processes, including rust prevention, ensure longevity. Finally, an extensive quality inspection is conducted, confirming that each sprocket meets the necessary standards for durability and functionality.

Applications of Finished Bore Sprockets

Finished bore sprockets are commonly used in various industries and applications, including:

- Heavy machinery and equipment, ensuring robust operation in demanding environments.

- Food processing and packaging, where precision and reliability are paramount.

- Chemical and pharmaceutical sectors, requiring components that can withstand harsh conditions.

- Assembly lines, facilitating efficient production processes.

- Logistics and warehousing, enabling smooth operation of material handling systems.

These sprockets are engineered specifically to transfer motion and power efficiently within these environments, thereby ensuring uninterrupted operations and reliability.

Maintenance and Care of Sprockets

To ensure the longevity and optimal performance of sprockets, proper maintenance and care are paramount. Here are some essential maintenance practices:

- Conduct daily inspections to identify any signs of damage, wear, or misalignment, allowing for early intervention where needed.

- Regular cleaning is vital for removing dirt and debris that can cause operational issues.

- Lubrication should be performed regularly to minimize friction and promote smooth operation between moving parts.

- Adjust and calibrate sprockets to maintain proper alignment, helping to prevent wear and extend their lifespan.

Common issues experienced with sprockets include tooth jumping, breakage, wear, excessive noise, and chain detachment. Addressing these issues can involve:

- For tooth jumping, inspect for misalignment or worn teeth, and readjust or replace sprockets as necessary.

- If breakage occurs, replace the faulty sprocket and check the chain for potential damage to avoid further issues.

- Regular lubrication helps minimize wear, while proper tension of the chain can further protect against undue strain on sprockets.

- To combat excessive noise, examine all components for looseness and apply lubrication as needed.

- In case of chain detachment, carefully reattach it, following the manufacturer’s guidelines for proper installation.

In addition to the FBN60B Asian Standard Finished Bore Sprocket, we offer a wide range of other sprocket types, such as taper lock sprockets, QD sprockets, and idler sprockets, along with an extensive variety of chain options to cater to diverse needs.

Sprockets Supplier in Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, focusing on high-quality sprockets and associated products. Among our featured offerings is the FBN60B Asian Standard Finished Bore Sprocket, crafted for durability and precision in performance. This sprocket is made from robust materials, ensuring optimal functionality across various applications. Our commitment to quality and customer satisfaction distinguishes us within the industry.

In addition to our standard sprockets, we also provide custom solutions tailored to meet our customers' specific requirements. We invite clients to share their designs or samples for non-standard customization, and our knowledgeable team is prepared to assist in creating the ideal product that aligns perfectly with your needs.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...