In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

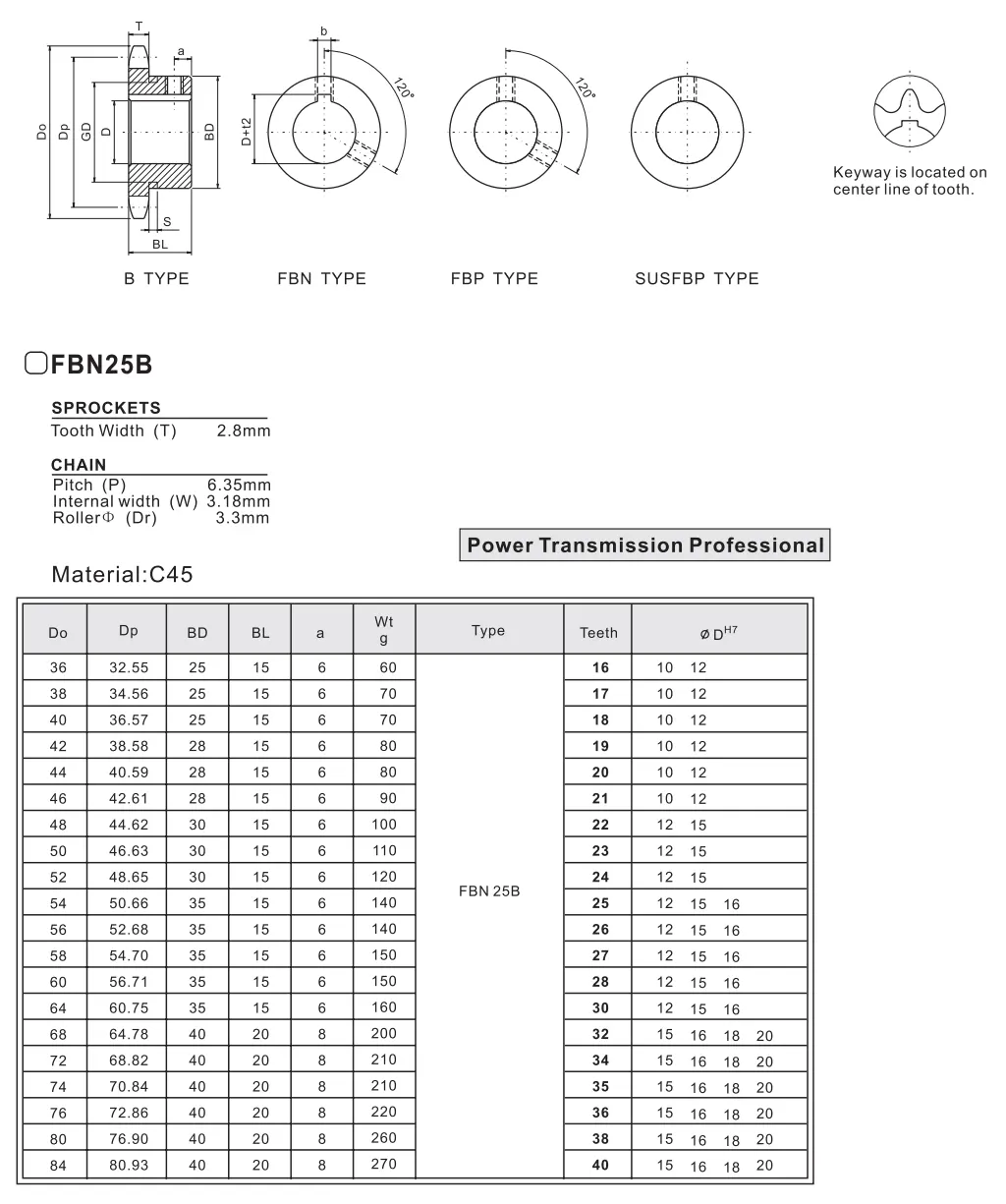

FBN25B Finished Bore Sprocket

The FBN25B Finished Bore Sprocket is designed for optimal performance and durability in various applications. Crafted from high-quality materials, this sprocket ensures precise fit and smooth operation. Ideal for industrial machinery, it supports efficient power transmission and enhances the longevity of your equipment, making it a reliable choice for all your needs.

Specifications of FBN25B Asian Standard Finished Bore Sprocket

The FBN25B finished bore sprocket is an essential component in power transmission and conveyor systems, as it efficiently transmits rotational force between two shafts. Recognized for its durability and performance, this Asian standard sprocket is available in various sizes and specifications to meet a wide range of application needs. Below is a more detailed overview of this finished bore sprocket:

Materials and Manufacturing Process

The FBN25B finished bore sprocket is carefully constructed from premium materials such as high carbon steel, alloy steel, or stainless steel. The selection of material is tailored to the specific application and operational environment in which it will be used. The manufacturing process involves multiple steps, including cutting, stamping, forging, machining, heat treatment, surface hardening, and rust prevention, all accompanied by stringent quality control measures. This meticulous approach ensures that each finished bore sprocket operates with high reliability and efficiency, even in demanding conditions.

Applications

This finished bore sprocket is widely utilized across several industries, including heavy machinery, food processing and packaging, chemicals, pharmaceuticals, assembly lines, logistics, and storage. It is specifically designed to withstand high loads and operate effectively under challenging conditions, making it a solid choice for various industrial applications where reliability is critical.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the FBN25B finished bore sprocket, proper maintenance is crucial. Regular inspection is necessary to identify any signs of wear, cracks, or damage. Keeping the sprocket clean is also essential; dirt and debris should be removed regularly to maintain its efficiency. Additionally, applying lubricants helps to minimize friction and wear, while also preventing rust and corrosion. Adjustments or calibrations may be needed to keep the sprocket aligned and the chain tension correct.

Frequent issues related to the sprocket may include tooth skipping, breakage, wear, excessive noise, and chain slippage. Here are some solutions to address these problems:

- Tooth skipping: Check chain tension and alignment, replacing the sprocket and chain if necessary.

- Breakage: Inspect the sprocket for any cracks or damage, replacing it if needed.

- Wear: Replace the sprocket when it shows significant wear or reaches its operational lifespan.

- Excessive noise: Look for loose or worn components and adjust or tighten them as required.

- Chain slippage: Verify the tension and alignment of the chain, adjusting or replacing the sprocket as needed.

Other Sprockets and Chains

In addition to the FBN25B finished bore sprocket, we offer a variety of other sprockets, including taper lock sprockets, QD sprockets, and idler sprockets, along with an extensive selection of chains. Our products are known for their high quality, reliability, and durability, making them suitable for a broad range of industrial applications worldwide.

Sprockets Supplier in the Netherlands

RP Techniek BV serves as the sales representative for Ever-power Group in the Netherlands, offering premium sprockets and associated products that cater to diverse industrial requirements. Our product lineup includes the FBN25B Asian Standard Finished Bore Sprocket, which is celebrated for its robustness and precision engineering. This sprocket is meticulously designed to provide outstanding performance across various applications, ensuring both reliability and longevity.

Alongside standard sprockets, our company specializes in customized non-standard solutions tailored to meet specific customer needs. We encourage clients to share their drawings or samples for custom sprocket solutions, allowing us to accommodate unique specifications and enhance operational efficiency.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...