The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

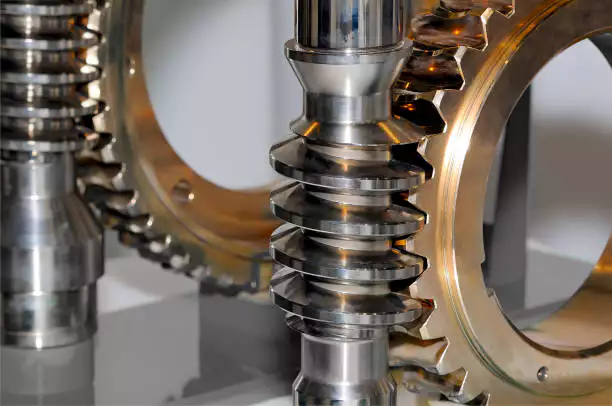

Double Enveloping Worm Gear

The Double Enveloping Worm Gear is a highly efficient gear system that provides a smooth motion transfer between the worm wheel I worm shaft. Made from durable materials, it enhances strength and longevity. This innovative design reduces friction, making it ideal for applications requiring reliable torque, thanks to its unique worm screw mechanism.

Details of Double Enveloping Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 5:1 |

| Efficiency | 90% |

| Tworzywo | Alloy Steel |

| Pressure Angle | 20 degrees |

| Max Load Capacity | 1500 Nm |

| Operating Temperature | -20°C to 100°C |

Features of Double Enveloping Worm Gear

- Wysoka wydajność: The Double Enveloping Worm Gear design allows for greater surface contact between the worm gear and worm wheel, resulting in reduced friction and improved efficiency compared to standard worm gears.

- Enhanced Load Capacity: This design increases the load-bearing capabilities of the worm shaft, making it suitable for heavy-duty applications where durability is essential.

- Smoother Operation: The unique shape of the worm screw contributes to smoother engagement and quieter operation, which is crucial for applications requiring precision and minimal noise.

Working Principle of Double Enveloping Worm Gear

The Double Enveloping Worm Gear is a mechanical device that employs a Worm Gear and a Worm Wheel to transmit power and motion with high efficiency. In this design, the Worm Shaft is enveloped by the Worm Wheel, providing a larger contact area and enhancing load-carrying capacity. This unique structure allows for smoother operation and reduced wear compared to traditional worm gears. Additionally, the Worm Screw design contributes to the effective conversion of rotational motion into linear movement, making the Double Enveloping Worm Gear ideal for various applications.

Manufacturing Process of Double Enveloping Worm Gear

The manufacturing process of the Double Enveloping Worm Gear involves several critical steps to ensure precision and efficiency. Below are the detailed points explaining the workflow and manufacturing techniques:

1. Design and Material Selection

The first step in the manufacturing of a Double Enveloping Worm Gear is the design phase. Engineers create detailed drawings and specifications for the Worm Gear, Worm Wheel, and associated components like the Worm Shaft and Worm Screw. Selecting the right materials is crucial, as it affects the durability and performance of the gear. Common materials include high-strength steel and alloyed metals that resist wear and fatigue, ensuring the worm gear operates smoothly under load.

2. Machining the Worm Shaft

Once designs are finalized, the Worm Shaft is machined using CNC (Computer Numerical Control) machines for high precision. This step involves cutting, shaping, and threading the shaft to the required specifications. The accuracy of the Worm Shaft is vital, as it directly influences the meshing with the Worm Wheel. The machining process must adhere to strict tolerances to achieve optimal performance, reducing friction and increasing efficiency in the gear assembly.

3. Manufacturing the Worm Wheel

The next phase is the manufacturing of the Worm Wheel. This component is typically created through gear hobbing or shaping, where the desired tooth profile is cut into the wheel. The Double Enveloping design allows for greater surface contact between the Worm Wheel and Worm Gear, enhancing load-carrying capacity and minimizing backlash. Quality control checks are conducted to ensure that the teeth have precise dimensions and are free from defects, which is essential for the smooth functioning of the assembly.

4. Heat Treatment

Heat treatment is an essential step that enhances the mechanical properties of the Worm Gear and Worm Wheel. This process involves heating the components to a specific temperature and then cooling them rapidly, which hardens the material. Proper heat treatment improves wear resistance and extends the lifespan of the gears. It is necessary to carefully control the heating and cooling cycles to avoid warping and to achieve the best mechanical characteristics.

5. Assembly and Testing

After all components are manufactured and treated, the final step is assembly. The Worm Gear is mated with the Worm Wheel, and the assembly is tested under various load conditions. This testing phase is crucial to ensure that the Double Enveloping Worm Gear operates smoothly and efficiently without any misalignment or excessive friction. Any necessary adjustments are made at this stage to guarantee optimal performance before the final product is delivered to the customer.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group, and we are proud to be one of the top ten worm gear suppliers in the Netherlands.

Our products, particularly the Double Enveloping Worm Gear, stand out in the market for several reasons:

- Exceptional Quality: We ensure that our worm gears are manufactured using the highest quality materials and advanced technology to provide durability and reliability.

- Top-notch Performance: Our Double Enveloping Worm Gears offer smooth operation and high efficiency, making them ideal for various industrial applications.

- Strong Industry Presence: With years of experience, we have established a reputation for excellence in the worm gear industry, backed by our extensive knowledge and expertise.

- Comprehensive Service: We pride ourselves on our customer service, providing expert support and guidance to help you choose the right products for your needs.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...