In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications of C2040HPSS Stainless Steel Hollow Pin Chain

- Material: Stainless steel

- Chain Type: Hollow Pin Chain

- Pitch Size: 1 inch

- Pin Diameter: 0.156 inches

- Plate Height: 0.591 inches

- Plate Thickness: 0.06 inches

- Breaking Load: 4,600 pounds

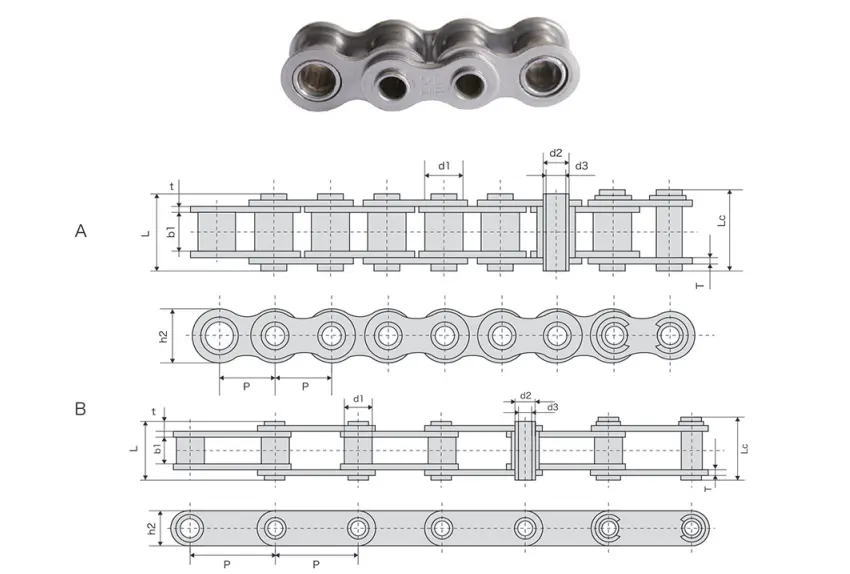

| Chain NIE |

Poziom | Bush? diameter | Width between inner plates |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Breaking Load |

Waga per meter |

Type |

| P | d1 | bl | d2 | d3 | L | LC | h2 | T | Q | q | ||

| max | min | max | min | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

1. Overview of C2040HPSS Stainless Steel Hollow Pin Chain

The C2040HPSS Stainless Steel Hollow Pin Chain is a highly durable and versatile chain that is specifically designed for applications requiring corrosion resistance and high strength. With its unique hollow pin design, this chain offers exceptional functionality and adaptability for various industrial applications.

2. Construction and Features

The C2040HPSS Stainless Steel Hollow Pin Chain is constructed using premium quality stainless steel, ensuring excellent resistance against corrosion, chemicals, and extreme temperature conditions. This chain features hollow pins that provide convenient access for attachments, making it ideal for conveyor systems, material handling equipment, and other industrial processes.

2.1 Stainless Steel Construction

The stainless steel construction of the C2040HPSS chain enhances its durability, allowing it to withstand harsh environments and demanding operating conditions. This makes it suitable for applications in the food processing, pharmaceutical, and chemical industries.

2.2 Hollow Pin Design

The hollow pin design of this chain allows for easy installation and attachment of various accessories, such as extended pins, flights, and buckets. The hollow pins also contribute to the overall weight reduction of the chain, resulting in improved energy efficiency and reduced system load.

3. Applications

The C2040HPSS Stainless Steel Hollow Pin Chain finds extensive use in a wide range of industrial applications, including:

3.1 Conveyor Systems

Due to its corrosion resistance and high strength, this chain is commonly employed in conveyor systems for the transportation of goods and materials. Its hollow pin design facilitates efficient attachment of custom accessories to meet specific handling requirements.

3.2 Material Handling Equipment

Material handling equipment, such as bucket elevators, typically utilize the C2040HPSS chain to ensure smooth and reliable operation in harsh environments. Its stainless steel construction enables it to withstand abrasive materials and chemical exposure.

3.3 Packaging Machinery

In packaging machinery applications, this stainless steel chain offers excellent resistance to moisture, chemicals, and wear, making it ideal for use in filling, capping, and labeling machines. Its hollow pin design allows for easy integration with various packaging components.

4. Benefits of C2040HPSS Stainless Steel Hollow Pin Chain

The C2040HPSS Stainless Steel Hollow Pin Chain provides numerous advantages for industrial applications:

4.1 Corrosion Resistance

With its stainless steel construction, this chain offers exceptional resistance against corrosion, allowing it to operate efficiently in environments with high humidity, chemical exposure, or extreme temperature fluctuations.

4.2 High Strength

The C2040HPSS chain is engineered to withstand heavy loads and provide reliable performance, ensuring minimal downtime and increased productivity in demanding industrial operations.

4.3 Versatility

Thanks to its hollow pin design, this chain can be easily customized and adapted to suit specific application requirements, allowing for efficient attachment of various accessories and enhancing overall operational flexibility.

4.4 Durability

The combination of stainless steel construction and precise manufacturing processes ensures the durability and longevity of the C2040HPSS chain, reducing the need for frequent replacements and maintenance, thus lowering overall operating costs.

4.5 Energy Efficiency

The lightweight nature of the C2040HPSS chain, achieved through its hollow pin design, contributes to improved energy efficiency in conveyor systems and material handling equipment, resulting in reduced power consumption and increased cost savings.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. With our expertise in the industry, we proudly present our C2040HPSS Stainless Steel Hollow Pin Chain, which showcases our unique selling points. Our chain stands out for its exceptional product quality, reliable service, and strong focus on customer satisfaction.

At RP Techniek BV, we take pride in our production capabilities - delivering durable and high-performing stainless steel roller chains. Our chains are meticulously manufactured using top-grade stainless steel materials, ensuring their longevity and resistance to corrosion in various environments.

In addition to our C2040HPSS Stainless Steel Hollow Pin Chain, we offer a wide range of other stainless steel roller chains. Our extensive selection guarantees that you will find the perfect chain for your specific needs, whether it be for industrial applications or machinery.

Experience the reliability and durability of our stainless steel roller chains. Choose RP Techniek BV as your trusted supplier for all your chain requirements.

Sprockets for Sale

When it comes to finding the right sprocket to go with your C2040HPSS stainless steel hollow pin chain, it's important to consider a few factors. Firstly, you want to make sure that the sprocket is made from a material that is compatible with the chain, such as stainless steel. Secondly, you want to ensure that the sprocket has the appropriate number of teeth to match the chain's pitch.

At our company, we offer a wide variety of sprockets to choose from, including those made from stainless steel and other materials. Our sprockets come in a range of sizes and tooth counts, so you can find the perfect match for your C2040HPSS chain.

In addition to our standard sprocket offerings, we also provide custom sprocket manufacturing services. This allows us to create a sprocket that is tailored to your specific needs, ensuring optimal performance and longevity.

No matter what type of sprocket you're looking for, we've got you covered. Contact us today to learn more about our sprocket selection and how we can help you find the perfect match for your C2040HPSS chain.

Informacje dodatkowe

| Editor | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...