In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications of 667J Stainless Steel Pintle Chain

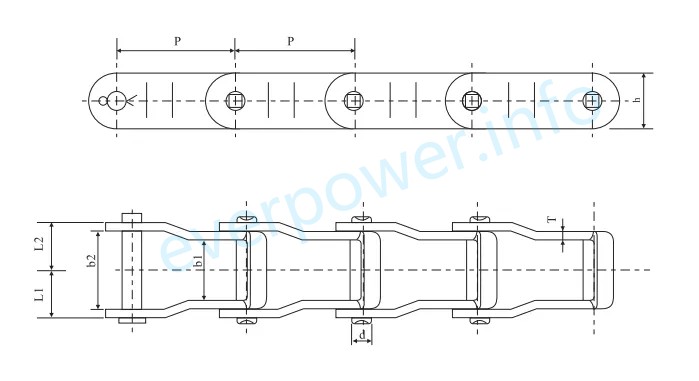

This section provides detailed parameters of stainless steel pintle chains.

Introduction of 667J Stainless Steel Pintle Chain

This 667J Stainless Steel Pintle Chain is a high-quality chain designed for various industrial applications. It is crafted using durable stainless steel material, ensuring excellent corrosion resistance and longevity. The chain's sturdy structure enables it to withstand heavy loads and extreme operating conditions. With its reliable performance, this pintle chain is an ideal choice for industries requiring reliable and efficient power transmission.

Advantages of 667J Stainless Steel Pintle Chain

Our 667J Stainless Steel Pintle Chain offers a number of advantages over other chains on the market. Firstly, its stainless steel construction means that it is highly resistant to corrosion and rust. This makes it ideal for use in environments where there is exposure to moisture or harsh chemicals.

Another advantage of the 667J chain is its strength. It is designed to handle heavy loads and can withstand the demands of even the toughest applications. This makes it a reliable choice for a wide range of industrial and agricultural settings.

The chain's pintle design also offers some unique benefits. Its open style allows for greater flexibility and easy maintenance, while the interlocking links ensure a secure fit and smooth operation. Additionally, it is compatible with a variety of attachments, making it a versatile option for many different tasks.

Overall, if you're looking for a strong, durable chain that can stand up to challenging conditions, our 667J Stainless Steel Pintle Chain is an excellent choice. See the image below for a visual representation of its features and design.

Applications of the 667J Stainless Steel Pintle Chain

The 667J Stainless Steel Pintle Chain is a versatile chain that finds its application in various industries and settings. Here are some key areas where this chain is commonly used:

1. Food Processing Industry: The 667J Stainless Steel Pintle Chain is widely utilized in food processing plants due to its corrosion-resistant properties. It is suitable for conveying and transferring food products, ensuring a hygienic and reliable operation.

2. Packaging Machinery: This chain is well-suited for packaging machinery, specifically in conveying and transporting packaged goods. Its high strength and durability make it suitable for handling heavy loads and operating in demanding environments.

3. Industrial Ovens and Furnaces: The 667J chain is frequently employed in industrial ovens and furnaces where high temperatures and harsh conditions are present. Its stainless steel construction allows it to withstand extreme heat and ensure smooth operation.

4. Waste Water Treatment: In waste water treatment plants, the 667J chain is used for various applications, including dewatering equipment, sludge conveyors, and grit removal systems. Its resistance to corrosion and abrasion make it ideal for such demanding environments.

5. Automotive Assembly Lines: This chain also finds its application in automotive assembly lines, where it is used for conveying components and ensuring efficient production processes. Its reliability and durability play a vital role in maintaining smooth operations.

Overall, the 667J Stainless Steel Pintle Chain is a versatile and reliable chain that is extensively used in the food processing industry, packaging machinery, industrial ovens, waste water treatment, and automotive assembly lines.

Maintenance Recommendations for 667J Stainless Steel Pintle Chain

Proper maintenance is crucial to ensure optimal performance and longevity of the 667J stainless steel pintle chain. Regular cleaning and lubrication are essential to keep the chain in top condition. Follow the steps below to correctly clean and lubricate the chain:

- Start by removing any accumulated dirt, debris, or contaminants from the chain. Use a soft brush or cloth to gently scrub the chain, paying close attention to the areas with more buildup.

- After cleaning, thoroughly rinse the chain with water to remove any remaining residue.

- Dry the chain completely using a clean cloth or compressed air. Ensure there is no moisture left on the chain surface.

- Apply a high-quality lubricant specifically designed for stainless steel chains. It is important to choose a lubricant that is resistant to water, heat, and corrosion.

- Use a lubrication brush or spray to evenly distribute the lubricant along the entire length of the chain. Make sure to reach all the inner links, rollers, and pins.

- Excess lubricant should be wiped off to prevent attracting dirt and contaminants.

Regular maintenance intervals should be established based on the chain's usage and operating conditions. By adhering to these maintenance recommendations, you can ensure that the 667J stainless steel pintle chain remains in optimal condition, maximizing its performance and lifespan.

Sprockets for Stainless Steel Chains

When it comes to selecting the right sprockets for your 667J Stainless Steel Pintle Chain, there are a few factors you should consider. Firstly, it's important to choose sprockets that are specifically designed for stainless steel chains to ensure maximum durability and performance. Stainless steel sprockets are resistant to corrosion, making them ideal for industries such as food processing, chemical manufacturing, and pharmaceuticals.

At our company, we offer a wide range of sprockets to suit various needs and applications. Our selection includes different types of sprockets, such as single, double, and triple strand sprockets, as well as taper lock sprockets and idler sprockets. Each type is carefully engineered to provide reliable performance and long-lasting service life.

Our sprockets are manufactured using high-quality materials and undergo rigorous testing to ensure they meet the highest standards. With our extensive range of sprockets, you can easily find the perfect match for your 667J Stainless Steel Pintle Chain, ensuring smooth operation and minimizing the risk of chain wear.

Why Choose Our Stainless Steel Pintle Chains?

At RP Techniek BV, we take pride in offering the highest quality stainless steel pintle chains. Our 667J Stainless Steel Pintle Chain is no exception. With its superior durability and strength, it is the ideal choice for various industrial applications.

One of our unique selling points is our commitment to product quality. Our stainless steel pintle chains undergo rigorous testing to ensure they meet the highest industry standards. This guarantees their reliability and longevity, even in demanding operating conditions.

Not only do we excel in product quality, but we also prioritize exceptional customer service. Our dedicated team is always ready to assist you with any inquiries or concerns, providing timely and knowledgeable support. We believe in building long-term relationships with our customers based on trust and satisfaction.

Furthermore, RP Techniek BV is the authorized sales agent for Ever-power Group in the Netherlands. This partnership allows us to offer a comprehensive range of stainless steel roller chains, in addition to the 667J Stainless Steel Pintle Chain. With our extensive selection, you can find the perfect chain for your specific needs.

Take a look at the image below to see the quality and craftsmanship of our stainless steel pintle chains.

Informacje dodatkowe

| Editor | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...