In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications of 662 Stainless Steel Pintle Chain

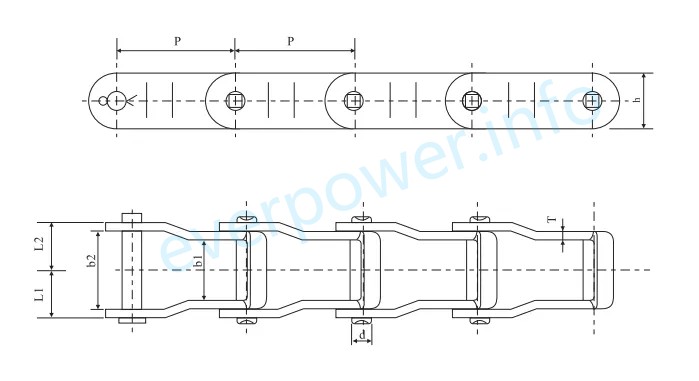

The following details are the specifications of stainless steel pintle chains.

Introduction of 662 Stainless Steel Pintle Chain

The 662 Stainless Steel Pintle Chain is made of durable stainless steel material, which guarantees long-lasting performance in various harsh environments. Its unique structure consists of interlocking links with pintle pins, allowing for smooth and reliable operation. This chain is commonly used in the food processing and packaging industry due to its resistance to corrosion and high temperatures. See the image below for a visual representation of the product:

Advantages of 662 Stainless Steel Pintle Chain

Our 662 Stainless Steel Pintle Chain offers exceptional strength, durability, and corrosion resistance. This chain is specifically designed for demanding applications where exposure to harsh environments is a concern.

One of the key advantages of our stainless steel pintle chain is its resistance to corrosion. The chain is constructed from high-quality materials that are resistant to rust, oxidation, and other forms of corrosion. This means that it can be used in harsh or corrosive environments without degrading or breaking down over time.

Another advantage of our stainless steel pintle chain is its exceptional strength and durability. This chain is designed to withstand heavy loads, extreme temperatures, and other harsh conditions without breaking or failing. As a result, it is ideal for use in a wide range of industrial applications, including food processing, pharmaceuticals, and packaging.

Overall, our 662 Stainless Steel Pintle Chain is a reliable and long-lasting solution for demanding applications that require exceptional strength and corrosion resistance.

Applications of 662 Stainless Steel Pintle Chain

The 662 Stainless Steel Pintle Chain is widely used in various industries due to its numerous beneficial properties. Here are some of the applications of this chain:

- Food Processing: The chain is ideal for food processing due to its ability to withstand high temperatures, corrosion resistance, and ease of cleaning.

- Beverage Industry: The 662 Stainless Steel Pintle Chain is a popular choice in the beverage industry because it is non-toxic, tasteless, and hygienic.

- Pharmaceutical Industry: The chain is also commonly used in the pharmaceutical industry due to its resistance to chemicals and high temperatures.

- Packaging Industry: This chain is used in the packaging industry because it can handle heavy loads and offers superior strength and durability.

- Automotive Industry: The 662 Stainless Steel Pintle Chain is used in the automotive industry due to its high tensile strength and resistance to wear and tear.

Maintenance Tips for 662 Stainless Steel Pintle Chain

To ensure the performance and longevity of your 662 Stainless Steel Pintle Chain, proper cleaning and lubrication are essential. Follow these maintenance recommendations to keep your chain in optimal condition:

1. Cleaning:

- Begin by removing any debris or dirt from the chain using a brush or compressed air.

- Prepare a solution of mild detergent and warm water.

- Dip a cloth or sponge into the solution and carefully wipe down the chain, removing any remaining dirt or grime.

- Rinse the chain thoroughly with clean water and pat it dry with a clean cloth.

2. Lubrication:

- Apply a high-quality lubricant specifically designed for stainless steel chains.

- Use a small brush or applicator to evenly distribute the lubricant along the length of the chain.

- Ensure that the lubricant reaches the rollers, pins, and bushings.

- Wipe off any excess lubricant to avoid attracting dirt and contaminants.

Regular maintenance is crucial for extending the life of your chain. Aim to clean and lubricate the 662 Stainless Steel Pintle Chain at least once every three months, or more frequently in harsh or demanding environments.

Remember to always refer to the manufacturer's guidelines for specific maintenance instructions. By following these recommendations, you can ensure that your stainless steel pintle chain remains in optimal condition, providing reliable performance for years to come.

Sprockets for Stainless Steel Chains

When it comes to selecting the right sprockets for your 662 Stainless Steel Pintle Chain, there are a few important factors to consider. First and foremost, it is essential to choose a sprocket that is compatible with the pitch of your chain. Using a sprocket with the wrong pitch can lead to premature wear and tear, as well as potentially catastrophic failure.

Another important consideration is the number of teeth on the sprocket. This will affect the speed ratio between the driving and driven shafts, so it is important to choose the right number of teeth to achieve the desired speed.

At our company, we offer a wide range of sprockets to suit all of your chain drive needs. From standard sprockets to custom designs, we can provide the perfect solution for your application. Our sprockets are made from high-quality materials and are designed to provide reliable and efficient performance, even in the most demanding environments.

Browse our selection of sprockets today to find the perfect match for your 662 Stainless Steel Pintle Chain. Contact us for more information on our products and services.

Why Choose Our Stainless Steel Pintle Chains?

Our 662 Stainless Steel Pintle Chain is the perfect choice for your industrial needs. At RP Techniek BV, we take pride in our unique selling points that set us apart from the competition.

One of our main strengths is the exceptional quality of our products. Our stainless steel pintle chains are made from high-grade materials, ensuring durability and long-lasting performance. We understand the importance of reliable equipment in your operations, and our chains are designed to withstand even the toughest conditions.

Another advantage of choosing RP Techniek BV is our commitment to customer service. Our team of knowledgeable professionals is dedicated to providing excellent support to our clients. We are always available to answer your questions, offer technical assistance, and ensure a smooth purchasing experience.

It is worth mentioning that RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. As a result, we have access to a wide range of stainless steel roller chains, offering even more options to meet your specific requirements.

With our extensive product range, exceptional quality, and outstanding customer service, RP Techniek BV is your trusted partner for all your stainless steel pintle chain needs. Contact us today to discover how we can assist you in achieving your goals.

Informacje dodatkowe

| Editor | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...