In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

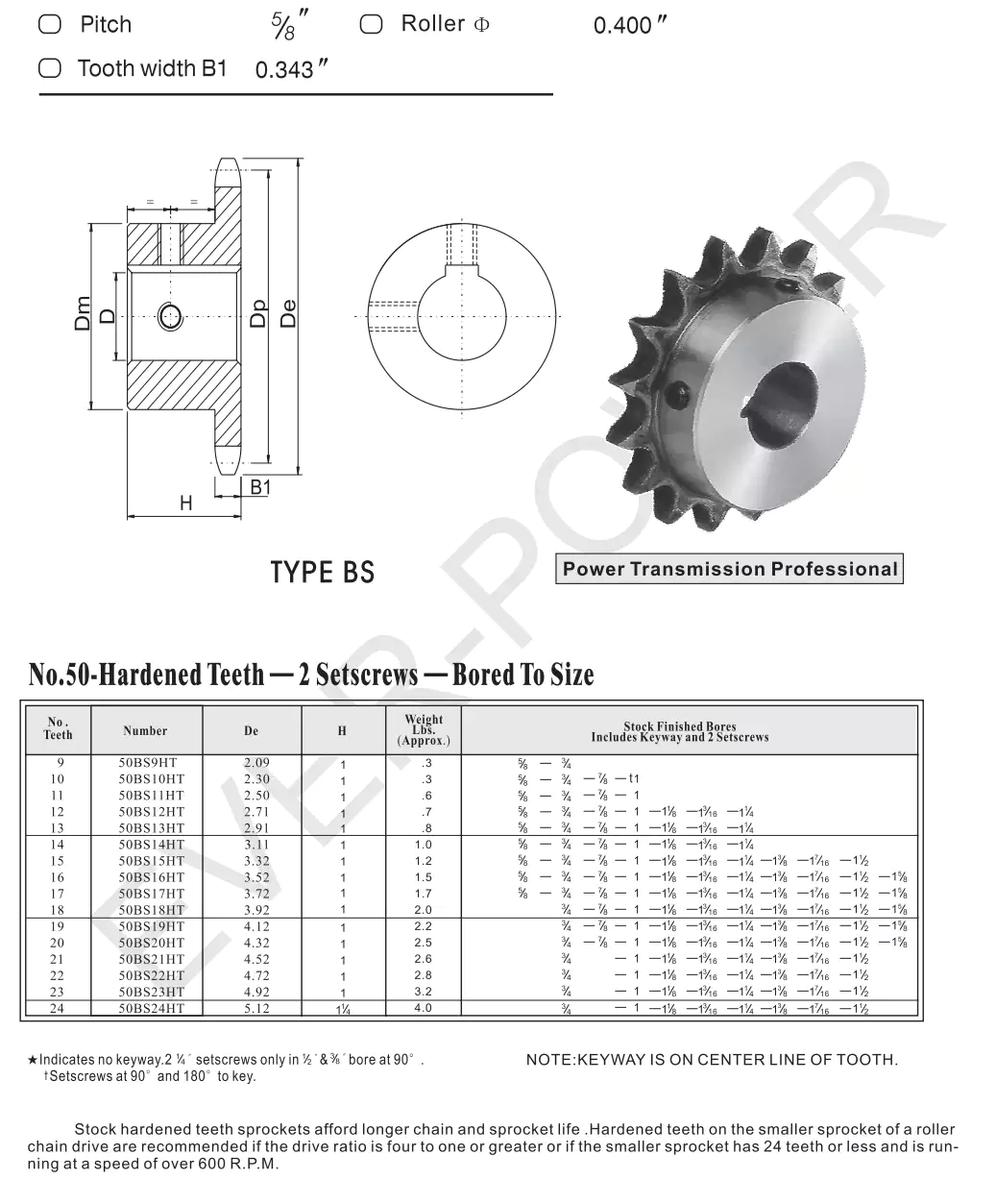

50BS*HT Finished Bore Sprocket

The 50BS*HT Finished Bore Sprocket is engineered for optimal performance in various industrial applications. Designed with precision, it ensures reliable power transmission and smooth operation. Its durable construction withstands heavy loads and reduces wear, making it an ideal choice for machinery and conveyor systems. Upgrade your equipment with this high-quality sprocket.

Specifications of 50BS*HT American Standard Finished Bore Sprocket

Introduction to Finished Bore Sprocket

The finished bore sprocket is a crucial component utilized across various industrial applications. This specific type of sprocket features a pre-bored hole, which simplifies the installation process on shafts or axles. Recognized for its exceptional efficiency and long-lasting durability, the finished bore sprocket caters to diverse operational requirements, making it a preferred choice in many settings.

Materials and Manufacturing Process

Manufactured from top-grade materials such as high carbon steel, alloy steel, or stainless steel, the finished bore sprocket is designed to endure demanding conditions. The production process encompasses multiple stages: from careful material selection to cutting, stamping, forging, and machining (including turning, milling, and drilling). Following these steps, the sprocket undergoes heat treatment through quenching and tempering, surface hardening, rust prevention measures, and thorough quality testing. These rigorous procedures are essential in guaranteeing the sprocket's strength, precision, and longevity.

Applications of Finished Bore Sprocket

Finished bore sprockets find extensive usage in various sectors such as:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical industries

- Assembly lines

- Logistics and warehousing

Maintenance and Care of Chain Sprockets

To ensure the durability and efficient performance of chain sprockets, regular maintenance and care are vital. Here are several key maintenance practices:

- Daily inspection: Consistently check for any signs of damage, wear, or misalignment to prevent further issues.

- Cleaning: It is essential to keep the sprocket free from dirt, debris, and the accumulation of lubricant to maintain optimal function.

- Lubrication: Appropriate lubrication should be applied to minimize friction, thus enhancing the overall performance of the sprocket.

- Adjustment and calibration: Regularly verify that the chain maintains proper tension and alignment to ensure effective operation.

Common issues that may develop with chain sprockets include tooth skipping, breakage, wear, excessive noise, and chain disengagement. Here are suggested solutions for these problems:

- Tooth skipping: Investigate misalignment or worn teeth and replace them as needed to restore functionality.

- Breakage: Check for any cracks or weak points, replacing the sprocket if it is found to be broken.

- Wear: Regular monitoring of the sprocket's wear is crucial, replacing it when it approaches its service limit.

- Excessive noise: Assess for potential misalignment, inadequate lubrication, or worn components that may cause unusual sounds.

- Chain disengagement: Ensure proper tension, alignment, and engagement of the chain to prevent disconnection during use.

Other Types of Sprockets and Chains

Beyond the 50BS*HT American Standard Finished Bore Sprocket, we provide a variety of other sprocket types, including taper lock sprockets, QD sprockets, and idler sprockets, as well as an extensive selection of chain types and models to suit your specific needs.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, a recognized leader in the sprocket manufacturing industry. Our company offers an extensive array of high-quality sprockets, including the 50BS*HT American Standard Finished Bore Sprocket, renowned for its durability and precision. This particular sprocket is well-suited for various applications, ensuring optimal performance and long-term reliability.

In addition to our standard selection of sprockets, we specialize in providing custom solutions tailored to meet the unique needs of our clients. Whether you require a specific design or unique dimensions, our experienced team is prepared to assist you in creating non-standard sprockets according to your specifications. We encourage all customers to share their drawings or samples for custom orders.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...