In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

#40 Chain Idler Sprocket

The #40 Chain Idler Sprocket is a crucial component designed to maintain proper tension and alignment in chain-driven systems. It helps reduce wear on chains and extends the lifespan of machinery by providing smooth operation. Commonly used in applications such as conveyors, agricultural equipment, and industrial machinery, this sprocket ensures efficient power transmission and reliable performance.

#40 Chain Idler Sprocket Parameters

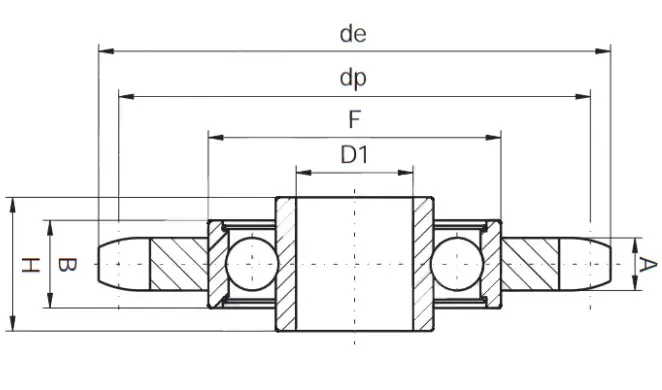

Ball Bearing Idler Sprockets

|

|

| Z | Poziom | de | dp | A | D1 | F | B | H | Chain Size |

| 18 | 1/2"×1/8" | 78.9 | 73.14 | 3 | 16 | 40 | 12 | 18.3 | #40 |

| 18 | 1/2"×3/16" | 78.9 | 73.13 | 4.5 | 16 | 40 | 12 | 18.3 | #40 |

| 16 | 1/2"×5/16" | 69.5 | 65.1 | 7.2 | 16 | 40 | 12 | 18.3 | #40 |

| 18 | 1/2"×5/16" | 77.8 | 73.14 | 7.2 | 16 | 40 | 12 | 18.3 | #40 |

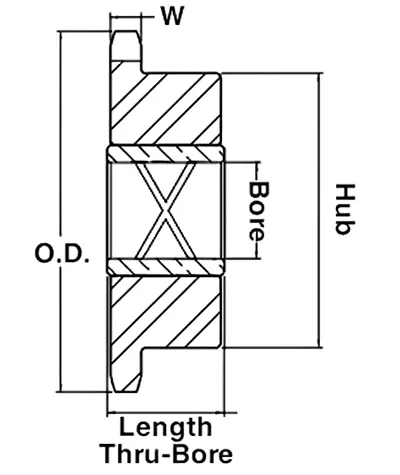

Needle Bearing Idler Sprockets

|

|

| Sprocket Size | Number Of Teeth | Bearing Type | Chain Size | Outside Diameter | Bore Size | Length Thru Bore | Dimension (T) | Hub Diameter | Waga |

| 40NB19H | 19 | Needle Bearing | #40 | 3.29" | 1.00" | 1.00" | 0.284" | 2.50" | 1.10 LBS |

Bronze Bearing Idler Sprockets

|

|

| Sprocket Size | Number Of Teeth | Bearing Type | Chain Size | Outside Diameter | Bore Size | Length Thru Bore | Dimension (T) | Hub Diameter | Waga |

| 40BR13 | 13 | Bronze Bearing | #40 | 2.33" | 1/2" | 0.94" | 0.284" | 1.56" | 0.50 LBS |

| 40BR19 | 19 | Bronze Bearing | #40 | 3.29" | 7/8" | 1.06" | 0.284" | 2.50" | 1.25 LBS |

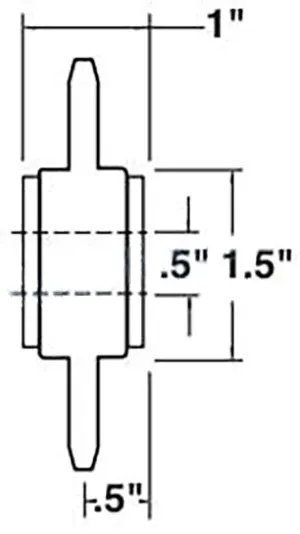

Bronze Bushed Idler Sprockets

|

|

| Sprocket Size | Number Of Teeth | Chain Size | Outside Diameter | Bore Size | Waga |

| 41E15 | 15 | #41 - #40 | 2.65" | 1/2" | 0.50 LBS |

#40 Chain Idler Sprocket Features

The #40 Chain Idler Sprocket offers a range of impressive features, including:

- Durable Construction: Made from high-quality materials to ensure long-lasting performance.

- Precision Engineering: Designed for optimal fit and function within chain systems.

- Odporność na korozję: Treated to withstand harsh environments and prevent rust.

- Easy Installation: User-friendly design allows for quick and hassle-free setup.

- Versatile Compatibility: Suitable for various applications, enhancing its usability.

Applications of #40 Chain Idler Sprocket

The #40 Chain Idler Sprocket is widely utilized across various industries, including:

- Agriculture: Used in agricultural machinery for efficient power transmission.

- Manufacturing: Essential in conveyor systems and assembly lines for material handling.

- Automotive: Employed in vehicles for smooth operation of chain drives.

- Mining: Found in heavy equipment for moving materials and ensuring reliability.

Different Idler Sprocket Types

The #40 Chain Idler Sprocket is available in various bearing types, each offering unique benefits. Ball bearing idler sprockets provide smooth operation and durability, while needle bearing idler sprockets are designed for high-load applications, offering greater efficiency. Bronze bearing idler sprockets excel in corrosion resistance, making them ideal for harsh environments. Choosing the right type depends on your specific application needs.

Idler Sprockets Manufacturer in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group, and we are one of the top sprocket suppliers in the Netherlands. Our company specializes in providing high-quality #40 Chain Idler Sprockets, designed for durability and optimal performance in various applications. We pride ourselves on offering excellent customer service and a comprehensive range of products that meet the needs of our clients.

In addition to standard products, we also provide custom solutions tailored to specific requirements. Our team is ready to assist customers with non-standard designs, ensuring that we can meet any unique specifications. We welcome clients to bring their drawings or samples for custom orders.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...