In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

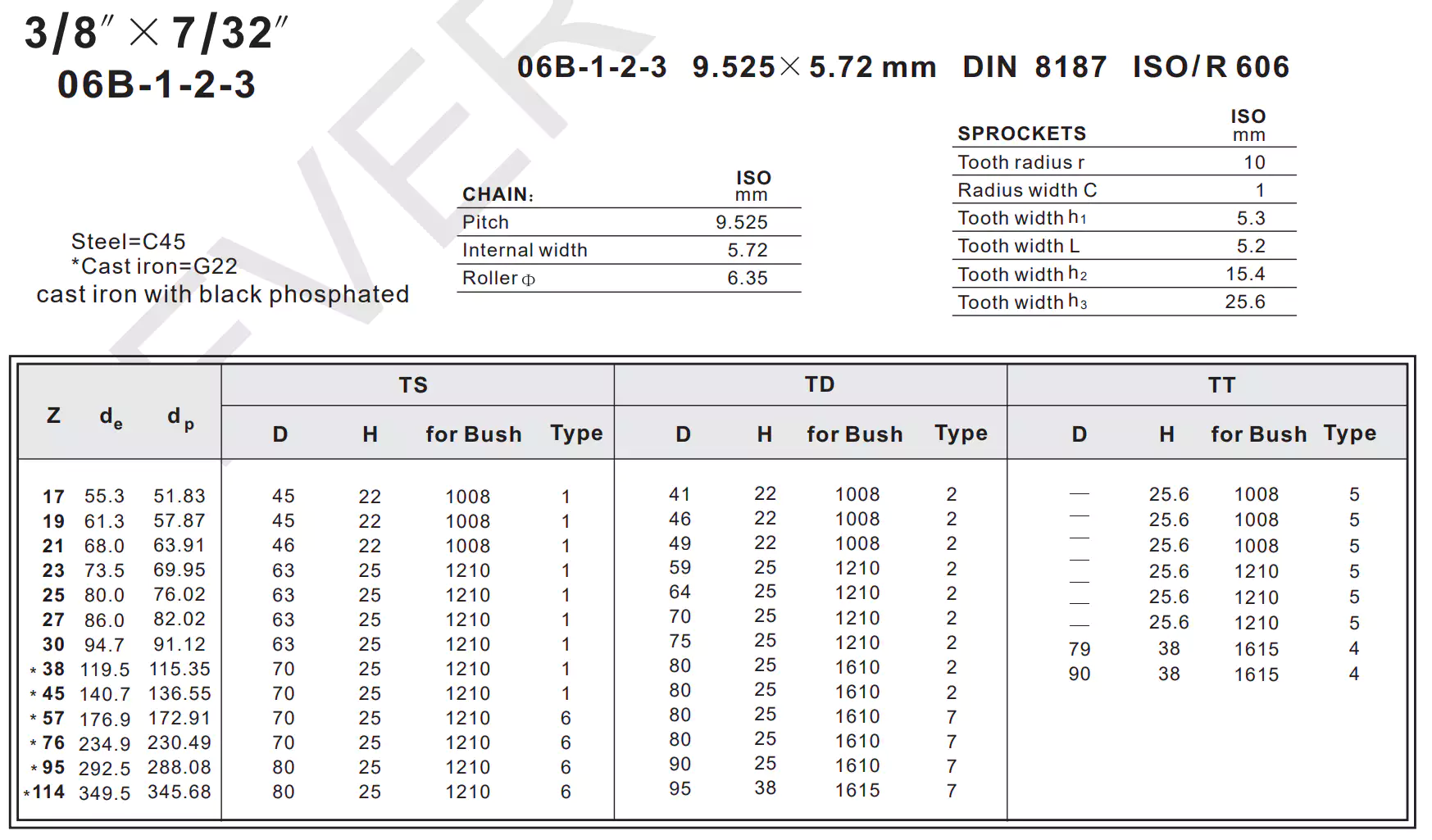

06B-1-2-3 3/8″ Taper Lock Sprocket

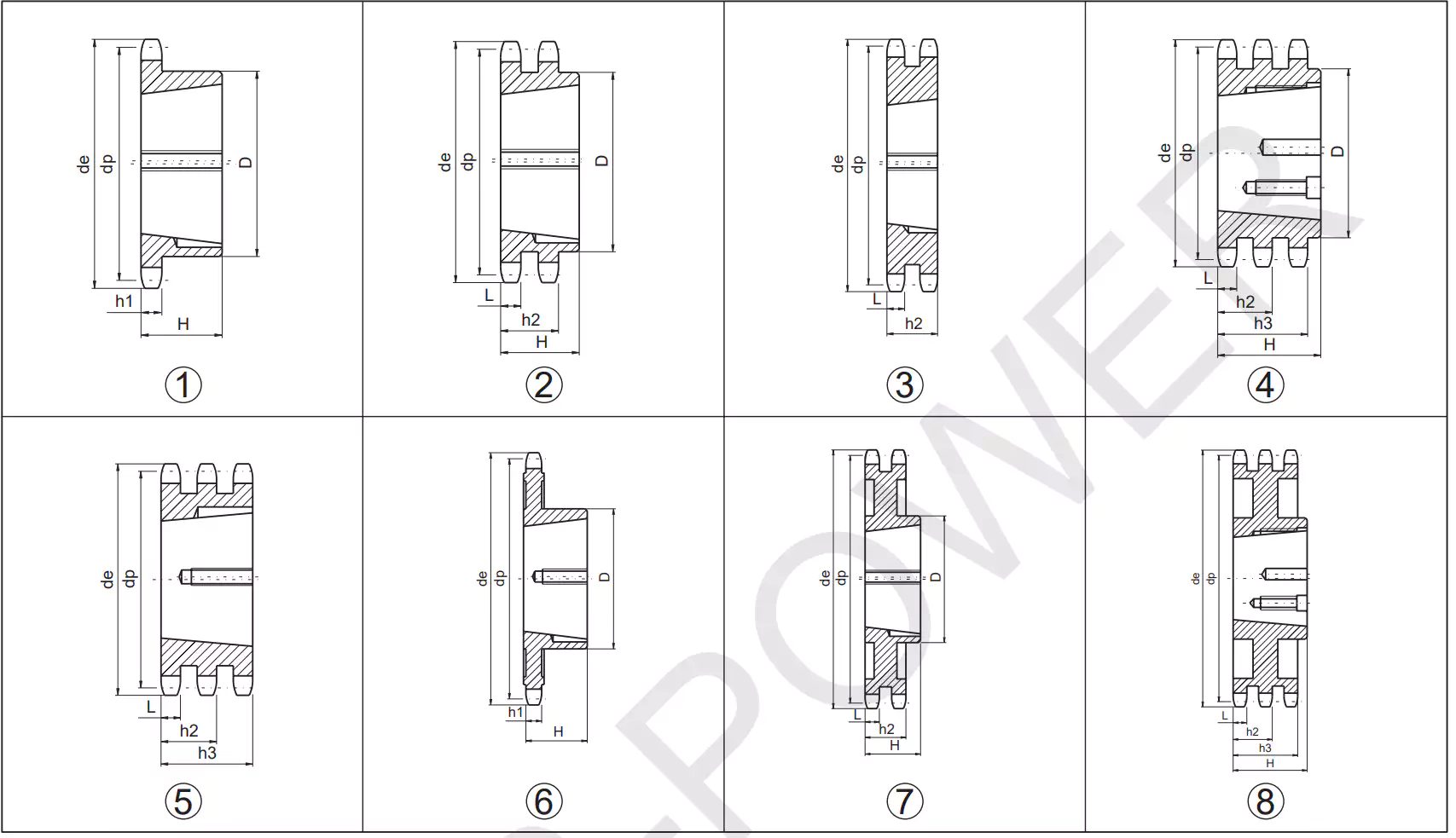

The 06B-1-2-3 3/8″ Taper Lock Sprocket is a precision-engineered component designed for reliability and performance in power transmission systems. This sprocket features a taper lock design that ensures easy installation and removal, providing a secure fit on shafts. Ideal for various applications, it enhances efficiency and minimizes downtime.

06B-1-2-3 3/8" Taper Lock Sprocket Specifications

The 06B-1-2-3 Taper Lock Sprocket, adhering to European standards, is a vital component in power transmission systems. Its innovative tapered bore design allows for effortless mounting onto shafts of varying sizes. This type of sprocket is widely utilized across multiple sectors including agriculture, mining, and construction, highlighting its essential role in efficient machinery operation.

Manufacturing Process

The manufacturing process for taper lock sprockets typically includes several crucial steps to ensure quality:

- Raw material preparation: Select high-quality steel or other suitable materials for the production of the sprocket, ensuring durability and strength.

- Cutting: Utilize cutting machines to shape the sprocket blank to precise dimensions as per specifications.

- Forging or casting: Employ forging or casting techniques to form the sprocket and enhance its structural integrity.

- Machining: CNC machines carry out precise operations such as drilling, turning, and milling to achieve the desired specifications.

- Tooth cutting: Specialized machinery is employed to cut the teeth of the sprocket, guaranteeing accuracy and a smooth finish.

- Heat treatment: Apply heat treatment processes to improve hardness, wear resistance, and overall toughness of the final product.

- Surface treatment: Implement coatings or plating techniques to enhance corrosion resistance and improve aesthetic appeal.

- Quality inspection: Conduct various tests and inspections to ensure that the sprocket meets all required specifications and industry standards.

Features and Functions

- Easy installation: Taper lock sprockets are engineered for simple installation and removal processes, significantly reducing time and labor expenses.

- High precision positioning: The tapered bore facilitates precise alignment on the shaft, which helps in minimizing both vibration and operational noise.

- Wide applicability: These sprockets can be used with a variety of shaft sizes and types of chains, enhancing their versatility.

- Reliability: Known for their strength and durability, taper lock sprockets are capable of withstanding demanding operating conditions.

- Low maintenance cost: With minimal upkeep requirements, taper lock sprockets help in lowering the overall maintenance costs associated with the system.

The ease of installation and removal of taper lock sprockets stands out, as they do not necessitate specialized tools or skilled labor for mounting. The tapered bore design ensures a secure and dependable connection between the sprocket and the shaft, which is critical for optimal performance.

Installation and Removal Process

To properly install and remove a taper lock sprocket, follow these outlined steps:

- Prepare tools and materials: Gather all necessary tools, which may include a torque wrench, hammer, and taper lock bushing for effective installation.

- Clean the shaft and sprocket surface: Ensure that any dirt, debris, or rust is thoroughly cleaned from both the shaft and the inner surface of the sprocket hub.

- Place the taper lock bushing: Carefully slide the taper lock bushing onto the shaft, positioning it according to the specific instructions provided by the manufacturer.

- Install the sprocket: Slide the sprocket onto the taper lock bushing, making sure to align it correctly with the keyway on the shaft for proper fitment.

- Tighten the locking nut: Use a torque wrench to securely tighten the locking nut to the manufacturer's recommended torque value, ensuring a firm attachment.

Sprockets Supplier in Netherlands

RP Techniek BV serves as a prominent supplier in the Netherlands, offering a comprehensive range of high-quality sprockets and related products. Among our offerings is the 06B-1-2-3 3/8" Taper Bore Sprocket, engineered for exceptional durability and efficiency across various applications. We pride ourselves on producing sprockets with precision, ensuring compatibility with a wide range of chain types while maintaining excellent performance standards.

Beyond our standard product lineup, RP Techniek BV also specializes in the manufacturing of custom, non-standard sprockets, tailored to fulfill specific customer needs. We invite clients to present their unique designs and samples for personalized solutions. Your satisfaction is our utmost priority, and we are dedicated to delivering products that meet your precise requirements.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...