In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

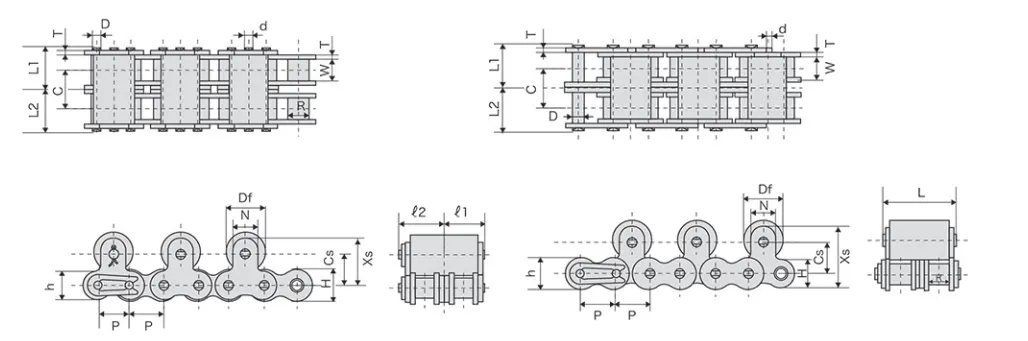

Specifications of 80-2-TRSS Double Strand Stainless Steel Conveyor Chains with Top Rollers

The 80-2-TRSS Double Strand Stainless Steel Conveyor Chains with Top Rollers have the following specifications:

- Chain Size: 80-2

- Chain Material: Stainless Steel

- Number of Strands: Double Strand

- Roller Type: Top Rollers

| Chain No | P | W | R | C | D | L1 | L2 | h | H | T | Df | Cs | Xs | N | L | ¦Ã1 | ¦Ã2 | d |

| 40-2-TRSS | 12.7 | 7.95 | 7.94 | 14.4 | 3.97 | 15.45 | 17.15 | 10.4 | 12 | 1.5 | 15.88 | 12.7 | 17.45 | 9.5 | 28.3 | 15.45 | 16.95 | 3.97 |

| 50-2-TRSS | 15.875 | 9.53 | 10.16 | 18.1 | 5.09 | 19.35 | 21.15 | 13 | 15 | 2 | 19.05 | 15.9 | 22.25 | 12.7 | 34.3 | 19.35 | 21.15 | 5.09 |

| 60-2-TRSS | 19.05 | 12.7 | 11.91 | 22.8 | 5.96 | 24.25 | 26.25 | 15.6 | 18.1 | 2.4 | 22.23 | 18.3 | 26.25 | 15.9 | 43.4 | 24.25 | 26.75 | 5.96 |

| 80-2-TRSS | 25.4 | 15.88 | 15.88 | 29.3 | 7.94 | 30.9 | 33.9 | 20.8 | 24.1 | 3.2 | 28.58 | 24.61 | 34.15 | 19.1 | 55 | 30.9 | 33.9 | 7.94 |

| 100-2-TRSS | 31.75 | 19.05 | 19.05 | 35.8 | 9.54 | 37.7 | 40.8 | 26 | 30.1 | 4 | 39.69 | 31.8 | 44.5 | 25.4 | 66.9 | 37.7 | 40.8 | 9.73 |

Przegląd

The 80-2-TRSS double strand stainless steel conveyor chains with top rollers are a type of conveyor chain that is made up of two parallel strands of stainless steel links connected by top rollers. These chains are commonly used in material handling applications that require high strength and corrosion resistance.

Features and Benefits

Stainless Steel Construction

One of the main features of these chains is their stainless steel construction. Stainless steel is a highly durable and corrosion-resistant material that can withstand harsh environments and extreme temperatures. This makes it an ideal choice for material handling applications that require high resistance to corrosion and wear.

High Strength

Another benefit of these chains is their high strength. Stainless steel is a strong material that can withstand heavy loads and extreme tension without breaking or deforming. This makes it an ideal choice for material handling applications that require high strength and durability.

Double Strand Design

The double strand design of these chains provides added strength and stability compared to single strand chains. The two parallel strands work together to distribute the load evenly, reducing stress on individual links and increasing the overall strength of the chain.

Top Rollers

The top rollers on these chains help to reduce friction and wear between the chain and the conveyor. The rollers allow the chain to move smoothly and quietly, reducing noise and vibration in the material handling system.

Applications

Food Processing

The high strength and corrosion resistance of these chains make them ideal for use in food processing applications. They can withstand exposure to harsh chemicals and extreme temperatures without corroding or degrading, ensuring that they can be used safely and reliably in food handling and processing applications.

Beverage Production

The smooth and quiet operation of these chains makes them ideal for use in beverage production applications. They can move products along the conveyor smoothly and without vibration, reducing the risk of spills and product damage.

Automotive Manufacturing

The high strength and durability of these chains make them ideal for use in automotive manufacturing applications. They can withstand the heavy loads and extreme tension that are common in automotive assembly lines, ensuring that they can be used safely and reliably to move parts and components along the production line.

Conclusion

The 80-2-TRSS double strand stainless steel conveyor chains with top rollers are a highly durable, corrosion-resistant, and versatile type of conveyor chain that is ideal for use in a wide range of material handling applications. Whether you are working in food processing, beverage production, automotive manufacturing, or any other industry that requires reliable and high-performance conveyor chains, these chains are an excellent choice.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. Our 80-2-TRSS Double Strand Stainless Steel Conveyor Chains with Top Rollers are a unique selling point that highlights the quality and service advantages of our products. We take pride in our production capabilities and commitment to delivering exceptional solutions for our customers.

We offer a wide range of stainless steel roller chains, in addition to our 80-2-TRSS model. Our chains are manufactured to the highest quality standards, ensuring long-lasting durability and superior performance. Our team of experts is dedicated to providing exceptional customer service and support, helping you find the perfect solution for your unique needs.

Sprockets for Sale

When it comes to the 80-2-TRSS double strand stainless steel conveyor chains with top rollers, finding the right sprocket is essential for optimal performance in your machinery. At our company, we offer a variety of sprockets that are compatible with this type of chain, ensuring that you can find the perfect fit for your needs.

Our range of sprockets includes different materials, sizes, teeth count, and styles. We understand that every application is unique and requires specific solutions, which is why we provide a diverse selection of sprockets. Whether you need a standard or custom-made sprocket, we have you covered.

Our sprockets are made with high-quality materials and precision manufacturing techniques. This ensures that they are durable, reliable, and can withstand heavy loads and harsh environments. Additionally, we offer competitive pricing and fast turnaround times so that you can get the sprockets you need when you need them.

Informacje dodatkowe

| Editor | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...