In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

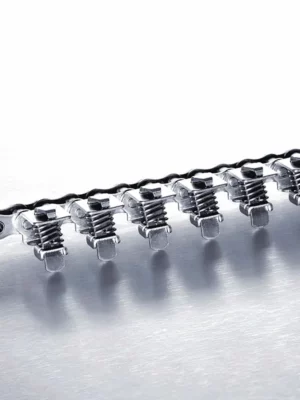

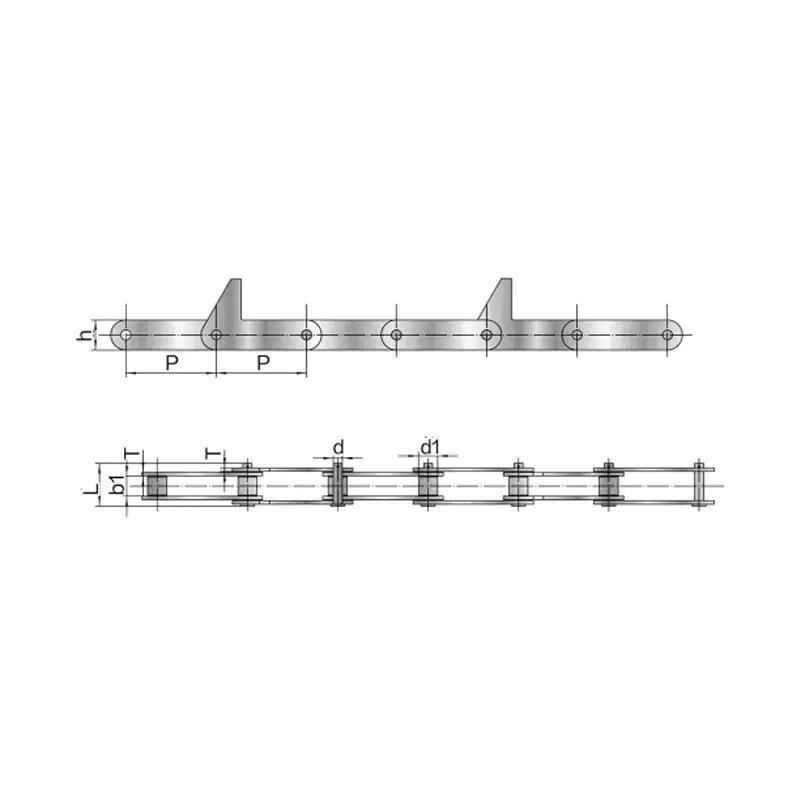

Details of Stainless Steel Metallurgical Washing Conveyor Chain SSWC100

Stainless Steel Metallurgical Washing Conveyor Chain SSWC100

1. Introduction

The Stainless Steel Metallurgical Washing Conveyor Chain SSWC100 is a high-quality product designed specifically for use in metallurgical washing applications. It is known for its durability, efficiency, and reliability, making it an ideal choice for industries that require a robust conveyor chain.

2. Key Features

With its advanced design and construction, the SSWC100 offers several key features that set it apart from other conveyor chains on the market:

- Stainless Steel Construction: The chain is made from high-quality stainless steel, ensuring excellent corrosion resistance and long-term performance.

- High Load Capacity: The SSWC100 is capable of handling heavy loads without compromising its structural integrity.

- Smooth Operation: The chain is designed to provide smooth and quiet operation, minimizing wear and tear on the equipment.

- Easy Maintenance: The SSWC100 is designed for easy maintenance, with features such as quick-access pins and removable links.

3. Applications

The SSWC100 is suitable for a wide range of applications in the metallurgical industry, including:

- Steel Manufacturing: The chain is ideal for conveying steel materials during the washing process, ensuring efficient and thorough cleaning.

- Foundries: It is commonly used in foundries to transport molten metal and other materials, withstanding high temperatures and harsh environments.

- Aluminum Production: The SSWC100 is well-suited for conveying aluminum products, thanks to its corrosion-resistant properties.

4. Installation

Installing the SSWC100 is a straightforward process that requires careful attention to detail. Follow these steps for a successful installation:

- Prepare the Conveyor: Ensure the conveyor is clean and free from any debris that may interfere with the installation.

- Attach the Chain: Place the SSWC100 onto the conveyor, aligning the links with the sprockets.

- Secure the Chain: Fasten the chain to the conveyor using the provided pins or connectors, ensuring a secure and reliable connection.

- Tension the Chain: Adjust the tension of the chain to the manufacturer's recommended specifications, ensuring proper operation and longevity.

5. Maintenance

To ensure the longevity and optimal performance of the SSWC100, regular maintenance is essential. Here are some maintenance tips:

- Regular Cleaning: Keep the chain clean by removing any dirt, debris, or residue that may accumulate during operation.

- Lubrication: Apply a suitable lubricant to the chain at regular intervals to minimize friction and prevent premature wear.

- Inspection: Periodically inspect the chain for any signs of damage or wear, such as bent or broken links.

- Replacement: If any components of the chain are damaged or worn beyond repair, replace them promptly to avoid further issues.

6. Conclusion

The Stainless Steel Metallurgical Washing Conveyor Chain SSWC100 is a reliable and durable solution for various metallurgical washing applications. Its exceptional features, ease of installation, and low maintenance requirements make it a preferred choice for industries that demand efficient and robust conveyor systems. Invest in the SSWC100 for long-lasting performance and peace of mind.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the authorized sales agent for Ever-power Group in the Netherlands. We are committed to providing our clients with high-quality stainless steel metallurgy industry chains, including the Stainless Steel Metallurgical Washing Conveyor Chain SSWC100 which is a unique product that we offer.

Our stainless steel metallurgy industry chains are produced with the latest technology and are composed of high-quality stainless steel, ensuring that they are durable and long-lasting. Our chains are highly resistant to corrosion, which makes them suitable for use in harsh environments such as those found in the metallurgy industry.

Moreover, we pride ourselves in providing excellent customer service to our clients. Our team of qualified experts is always ready to provide professional advice and technical support to ensure that you get the best product for your needs.

At RP Techniek BV, we have the capability to produce a wide range of stainless steel roller chains to suit different applications. Our production line is equipped with state-of-the-art technology, and our team of professionals is highly skilled and experienced in producing high-quality chains that meet international standards.

Choose us for all your stainless steel metallurgy industry chains needs, and we guarantee that you will not be disappointed. Contact us today to learn more about our products and services.

How to Select Suitable Sprockets?

When it comes to choosing the right sprockets for the Stainless Steel Metallurgical Washing Conveyor Chain SSWC100, there are a few factors to consider. Firstly, it is important to determine the desired speed ratio and torque requirements for the application. This will help in selecting the appropriate pitch diameter and number of teeth for the sprocket.

Additionally, one must consider the material of the sprocket. In the case of the Stainless Steel Metallurgical Washing Conveyor Chain SSWC100, stainless steel sprockets would be the most suitable choice. Stainless steel offers excellent corrosion resistance and durability, making it ideal for applications that involve exposure to harsh environments or chemicals.

Moreover, our company proudly offers a wide range of sprockets for sale to meet various needs. We provide different types of sprockets, including those with various tooth profiles and hub configurations. Our products are carefully designed and manufactured to ensure reliable performance and longevity.

In conclusion, selecting suitable sprockets for the Stainless Steel Metallurgical Washing Conveyor Chain SSWC100 involves considering the desired speed ratio, torque requirements, and material compatibility. Our company offers a diverse selection of high-quality sprockets to ensure optimal performance and customer satisfaction.

Informacje dodatkowe

| Editor | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...