Stainless steel welded chains are commonly used in hoisting applications due to their strength, durability, and resistance to corrosion. In Brussels, where heavy loads need to be lifted and transported, these chains are the go-to choice for many industries. In this article, we will explore the benefits of stainless steel welded chains and their applications in hoisting in Brussels.

Benefits of Stainless Steel Welded Chains

Stainless steel welded chains offer a range of benefits, making them ideal for hoisting applications. Some of these benefits include:

- High strength and durability

- Resistance to corrosion and rust

- Low maintenance requirements

- Ability to withstand high temperatures

- Excellent fatigue resistance

These benefits make stainless steel welded chains a reliable and cost-effective solution for hoisting in Brussels.

Applications of Stainless Steel Welded Chains in Hoisting

Stainless steel welded chains are used in a variety of hoisting applications in Brussels, including:

Construction

In the construction industry, stainless steel welded chains are used to lift and transport heavy loads, such as steel beams, concrete blocks, and building materials. These chains are ideal for use in harsh environments, where they can withstand exposure to dust, dirt, and moisture.

Marine

Stainless steel welded chains are also used in the marine industry for hoisting and anchoring applications. These chains are resistant to corrosion from saltwater and can withstand the harsh conditions of the ocean.

Transportation

Stainless steel welded chains are used in the transportation industry for hoisting heavy cargo, such as shipping containers and machinery. These chains are strong enough to withstand the weight of the cargo and can be easily attached to cranes and other lifting equipment.

Maintenance of Stainless Steel Welded Chains

To ensure the longevity and reliability of stainless steel welded chains, proper maintenance is essential. Regular inspection and cleaning can help to prevent corrosion and ensure that the chains are in good working condition.

When cleaning stainless steel welded chains, it is important to use a mild detergent and avoid harsh chemicals that can damage the chain's surface. After cleaning, the chain should be thoroughly rinsed with water and dried to prevent moisture buildup.

Conclusion

Stainless steel welded chains are a reliable and cost-effective solution for hoisting heavy loads in Brussels. Their high strength, durability, and resistance to corrosion make them ideal for use in harsh environments, such as construction sites, marine applications, and transportation. Proper maintenance is important to ensure the longevity and reliability of these chains.

Choose Our Stainless Steel Welded Chains

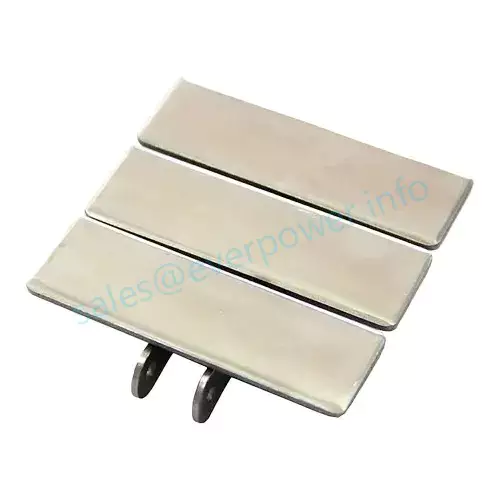

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands, and we are proud to provide our customers with the highest quality stainless steel welded chains for hoisting in Brussels. Our welded chains are manufactured using the finest stainless steel materials, ensuring a long-lasting and durable product that is perfect for heavy-duty applications.

At RP Techniek BV, we pride ourselves on our unique selling points. Our products are of the highest quality, and we offer exceptional customer service to ensure that our customers have the best experience possible. Our production facility is state-of-the-art, and we have a team of highly skilled professionals who are dedicated to producing the best stainless steel welded chains available in the market.

In addition to our stainless steel welded chains for hoisting in Brussels, we also offer a wide range of other stainless steel roller chains for sale. Whether you need a standard roller chain or a custom chain designed to meet your specific requirements, RP Techniek BV has the expertise to provide the perfect solution for your needs.

Edited By Zqq.