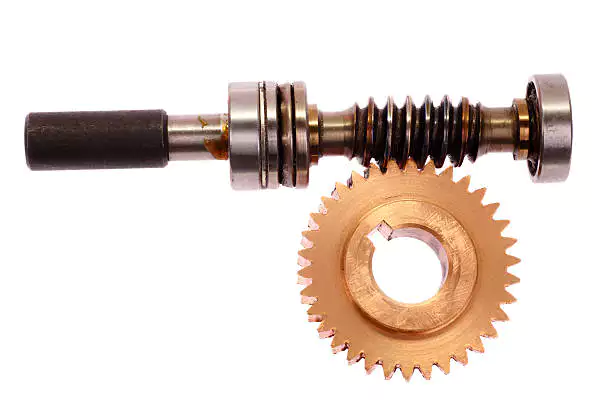

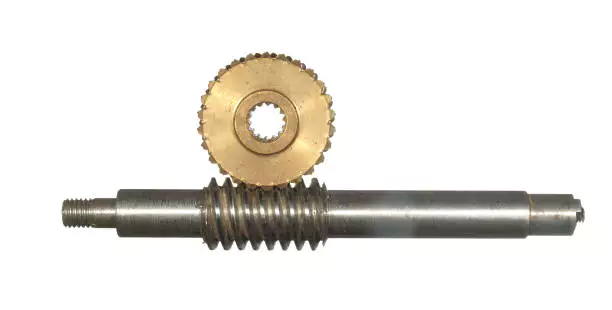

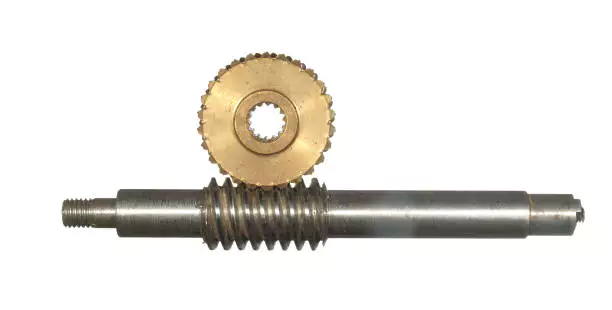

The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Worm Gear in Hoists

The worm gear in hoists is a crucial component designed to provide efficient torque transmission and control in lifting applications. This type of worm gear in hoist equipment allows for smooth operation, making it ideal for various hoist worm gear applications. Its self-locking properties ensure safety during lifting operations, which is essential in industrial settings. The worm gear for industrial lifting enhances the reliability of worm gear in hoist mechanisms, making it a preferred choice in many lifting solutions.

Specifications of Worm Gear in Hoists

| Specification | Details |

|---|---|

| Gear Ratio | 10:1 |

| Tworzywo | High-Strength Steel |

| Load Capacity | 2000 kg |

| Moment wyjściowy | 150 Nm |

| Efficiency | 85% |

| Operating Temperature | -40°C to 100°C |

Why Worm Gears are Suitable for Worm Gear in Hoists

Worm gears are ideal for hoists due to several key advantages:

- Self-Locking Mechanism: The self-locking worm gear for hoists prevents back-driving, ensuring safety during lifting operations.

- Compact Design: Worm gear in hoist equipment maximizes space efficiency while providing high torque output.

- Smooth Operation: The design of worm gear in hoist mechanisms allows for quiet and smooth operation, reducing wear and tear.

- Versatility: Used widely in hoist worm gear applications, they are suitable for various industrial lifting tasks.

- Durability: Built for heavy-duty performance, worm gear for industrial lifting can withstand harsh conditions.

How Worm Gears Work in Hoists

Worm gears play a crucial role in hoists, providing effective torque transmission and enhanced load control. In worm gear in hoists, the unique design allows for self-locking capabilities, making them ideal for self-locking worm gear for hoists. This ensures that the load remains secure when the hoist is not in operation. Commonly utilized in hoist worm gear applications, these gears allow for smooth lifting and lowering of heavy loads. The worm gear in hoist equipment is engineered for durability, making it suitable for worm gear for industrial lifting tasks. The innovative worm gear in hoist mechanisms ensures reliability and efficiency in various lifting operations.

Manufacturing Process of Worm Gear in Hoists

- Material Selection: The first step in the manufacturing process of worm gear in hoists involves selecting high-quality materials that ensure durability and strength. Common materials include carbon steel and bronze, which are ideal for worm gear in hoist equipment. These materials not only provide the necessary strength for industrial lifting but also enhance resistance to wear and fatigue. The right material choice is crucial for achieving long-lasting performance in hoist worm gear applications.

- Precision Machining: After material selection, the worm gear is subjected to precision machining, which includes processes like turning, milling, and grinding. This step is vital to achieving the exact dimensions and tolerances required for worm gear in hoist mechanisms. Precision machining ensures that the self-locking worm gear for hoists fits perfectly into the assembly, preventing slippage and enhancing the overall efficiency of the hoist system.

- Heat Treatment: To improve the hardness and durability of the worm gear, heat treatment is applied. This process involves heating the gear to a specific temperature and then quenching it to achieve the desired hardness. Heat-treated worm gear for industrial lifting applications can withstand higher loads and resist deformation over time. This step is essential in enhancing the performance and lifespan of the worm gear in hoists.

- Surface Finishing: The final step in the manufacturing process is surface finishing. This includes processes such as polishing and coating to improve corrosion resistance and reduce friction. A well-finished surface on the worm gear in hoists reduces wear and extends the life of the gear, ensuring smooth operation in hoist worm gear applications. Proper surface treatment also contributes to the reliability of the self-locking mechanism in hoisting systems.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands and is recognized as one of the top ten worm gear suppliers in the country.

Our offerings include:

- High-Quality Products: We pride ourselves on providing worm gears that meet the highest industry standards, ensuring reliability and durability.

- Exceptional Craftsmanship: Each product is manufactured with precision, guaranteeing optimal performance in various applications.

- Strong Reputation: As a leading supplier, our expertise and experience in the market make us a trusted partner for your worm gear needs.

- Comprehensive Services: We offer excellent customer support, ensuring timely delivery and assistance throughout your purchasing process.

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...