In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Winch Planetary Gearbox for Bridge Suspension Lifting Equipment

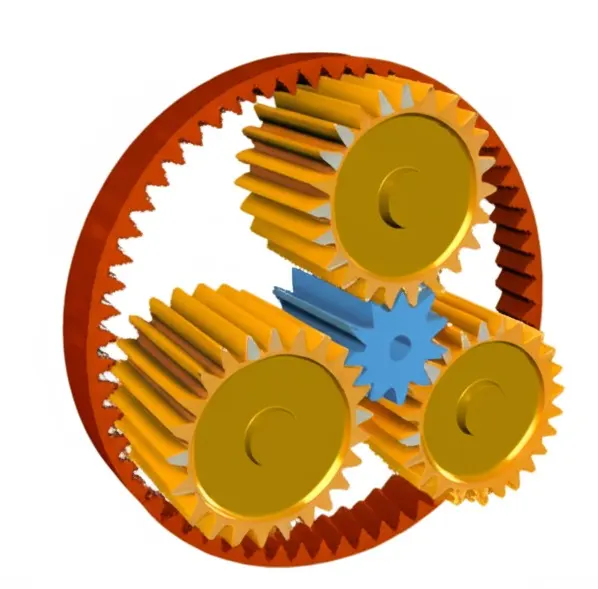

The Winch Planetary Gearbox for Bridge Suspension Lifting Equipment is a crucial component designed to enhance the lifting capabilities of bridge structures. This gearbox utilizes a planetary gear system that provides high torque and efficient power transmission, ensuring smooth and reliable operation during lifting tasks. Ideal for bridge maintenance and construction, it ensures safety and efficiency, making it an essential tool for handling heavy loads in suspension lifting applications.

Features and Specifications of Winch Planetary Gearbox for Bridge Suspension Lifting Equipment

| Specification | Details |

|---|---|

| Output torque range | 1000-280000 N.m |

| Gear ratios | i=5.3-400 |

| Support | The gearbox has rotating housing flanges to fit winch |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve on request |

| Łożysko | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake on request |

| Performance figures | Refer to FEM standards, class M5 (T5-L2) for output max. speeds of 25 rpm |

| Compatibility | Technical data and installation dimensions of the EP400W Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 800 Series, so these three can be used interchangeably |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP400W1 | 870 | 6.09 | 1000 | 130 |

| EP401W1 | 1300 | 6.2 | 1000 | 270 |

| EP402W2 | 4000 | 12.4-37.1 | 3500 | - |

| EP403W2 | 4000 | 15.4-40 | 3500 | 270 |

| EP405W | 7000 | 20-80 | 3500 | 270 |

| EP405.4W | 5500 | 26-57 | 3500 | 280 |

| EP406AW | 12500 | 23-220 | 3500 | 430 |

| EP406W | 13000 | 28-140 | 3500 | 430 |

| EP406BW3 | 17500 | 63-136 | 3500 | 430 |

| EP407AW | 18000 | 38-136 | 3500 | 430-530 |

| EP407W3 | 26000 | 63-136 | 3500 | 530 |

| EP410W3 | 37500 | 62-177 | 3500 | 530 |

| EP413W3 | 42500 | 86-172 | 3500 | 610 |

| EP414W3 | 67000 | 76-186 | 3500 | 1200 |

| EP415W3 | 100000 | 81-215 | 3000 | 1200 |

| EP416W3 | 140000 | 87-255 | 3000 | 2000 |

| EP417W3 | 200000 | 123-365 | 3000 | 2000 |

| EP419W3 | 275000 | 161-306 | 2500 | 3000 |

Winch Planetary Gearbox for Bridge Suspension Lifting Equipment

The winch planetary gearbox operates by utilizing a system of gears that distribute torque efficiently to lift heavy loads, such as bridge suspension systems. Its basic structure consists of a central sun gear, planet gears, and a ring gear. As the sun gear rotates, the planet gears orbit around it, transferring power to the ring gear. This unique arrangement allows for a compact design while providing high torque output, making it ideal for lifting applications. The gearbox ensures smooth and reliable operation when adjusting the suspension of bridges, facilitating safe and efficient maintenance.

Advantages of Winch Planetary Gearbox for Bridge Suspension Lifting Equipment

- High Torque and Load Capacity: The multi-tooth engagement design effectively distributes loads, enhancing the overall load-bearing capacity.

- Compactness and Space Efficiency: This gearbox boasts a size advantage over traditional gearboxes, making it ideal for installations with limited space.

- Transmission Efficiency: Achieving an efficiency of 97%-98% in single-stage configurations and excellent performance in multi-stage setups.

- Durability and Reliability: Uniform stress distribution contributes to a longer lifespan, ensuring consistent performance under load.

- Customizability: The gearbox can be tailored to different winching requirements by adjusting gear ratios, torque, and installation methods.

Selection Guide for Winch Planetary Gearbox

When selecting a Winch Planetary Gearbox for Bridge Suspension Lifting Equipment, consider the following factors: the required power or torque, gear ratio, and operational speed. Assess the input and output types, such as spline, hollow, or solid, and whether the input/output ends will experience external or radial loads. Additionally, evaluate the working temperature, lifespan requirements, and any special needs like continuous operation or shock resistance.

Winch Planetary Gearbox for Bridge Suspension Lifting Equipment

How to Reduce Operating Noise of Winch Planetary Gearbox?

To minimize operating noise in winch planetary gearboxes for bridge suspension lifting equipment, precision machining and optimized gear design are crucial. Employing high-precision fabrication techniques ensures that components fit together tightly, reducing vibrations that contribute to noise. Additionally, utilizing specially designed gears with improved tooth profiles can lead to smoother meshing, thus lowering operational sound levels. These strategies not only enhance performance but also extend the lifespan of the equipment.

Key Strategies for Noise Reduction

- Implement high-precision machining for better component fit.

- Design gears with optimized tooth profiles for smoother engagement.

- Utilize appropriate lubricants to minimize friction and wear.

- Incorporate sound-dampening materials in the housing design.

Winch Planetary Gearbox Manufacturer

RP Techniek is the Dutch sales agent for Ever-power Group, specializing in high-quality mechanical solutions. The Winch Planetary Gearbox plays a crucial role in bridge suspension lifting equipment, providing the necessary torque and precision for safe and efficient lifting operations. Its robust design ensures reliability and longevity, making it an essential component in the demanding environments of bridge construction and maintenance.

We encourage our valued customers to consider customizing and purchasing our Winch Planetary Gearboxes to meet their specific needs. Enhance your operational efficiency and ensure safety with our top-of-the-line products!

Informacje dodatkowe

| Edited | Zqq |

|---|

Zaktualizowano blogi

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...