In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery.

Basic Structure and Function of the Transmission Chain

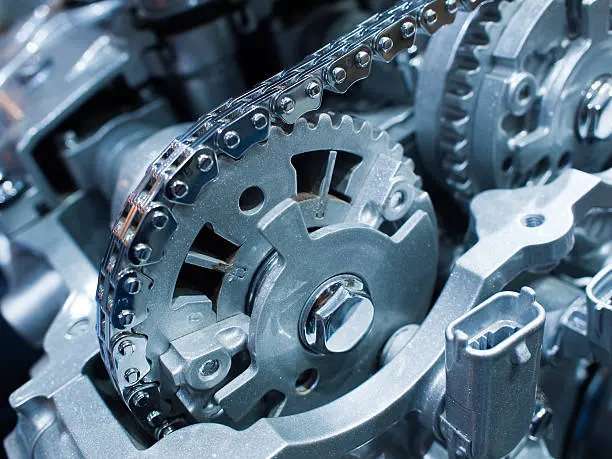

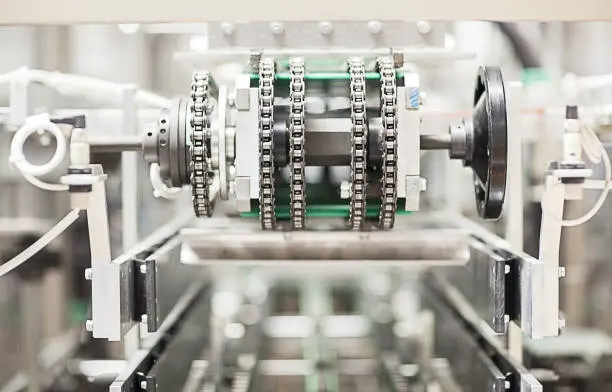

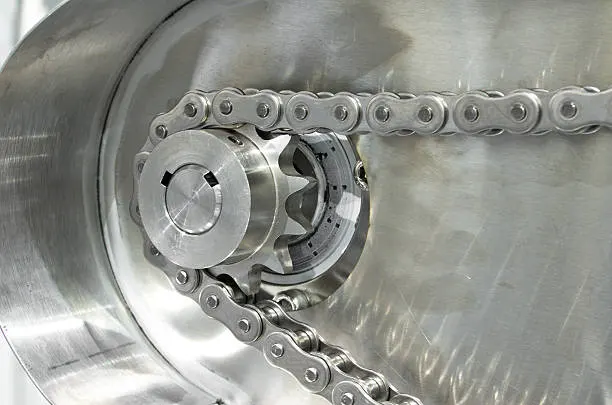

The transmission chain is a mechanical device composed of multiple chain links connected by hinges, usually consisting of inner chain plates, outer chain plates, pins, rollers, and sleeves. Its main function is to transfer power from the power source (such as a motor or engine) to the actuator (such as a gear, roller, or workbench) to achieve mechanical movement.

Types of Transmission Chains

- Roller Chain: The most common type of transmission chain, suitable for medium and low-speed and heavy load conditions.

- Silent Chain: Smooth operation, low noise, often used for high-precision transmission.

- Toothed Chain: Has high transmission efficiency and load-bearing capacity, suitable for high-speed transmission.

The Impact of the Transmission Chain on Mechanical Efficiency

-

Loss of Transmission Efficiency

The transmission chain will generate a variety of energy losses during operation, mainly including:- Friction Loss: Friction between chain links and friction between the chain and sprocket will cause energy loss.

- Vibration and Shock: Uneven movement or looseness of the chain can cause vibration and shock, further reducing efficiency.

- Poor Lubrication: Lack of lubrication or improper lubrication will increase friction resistance, resulting in reduced efficiency.

-

Reduced Transmission Accuracy

Wear, stretching, or deformation of the transmission chain will affect the accuracy of the transmission and cause inaccurate mechanical movement. For example, in an automated production line, errors in the transmission chain may lead to a decrease in product processing accuracy, thus affecting overall production efficiency. -

Stability of Energy Transmission

The design and installation quality of the transmission chain directly affect the stability of energy transmission. If the chain is too tight or too loose, it will cause uneven energy transmission, which will in turn affect the operating efficiency of the machine.

Enhance the Mechanical Efficiency of the Transmission Chain

- Cut Down on Friction

To Cut Down on Energy Loss, Use High-Quality Lubricants and Low-Friction Bearings. - Boost the Quality of the Component

Reduce Energy Loss, Optimize Gear Design, and Use Lightweight, High-Strength Materials. - Improve the Layout of the Transmission

Reduce the Transmission Path, Make Sure All the Parts Are Aligned, and Steer Clear of Vibration and Misalignment. - Choose Effective Transmission Techniques

Depending on Your Needs, Choose an Efficient Transmission Type (Belt Drive, Chain Drive, etc.) and Integrate Technology for Variable Frequency Speed Regulation. - Frequent Upkeep

To Maintain the System Functioning Well, Examine, Clean, and Replace Worn Parts on a Regular Basis. - Cut Down on Vibration and Clearance

Reduce Vibration and Noise, Adjust Dynamic Balancing, and Remove Transmission Clearance.