Invoering

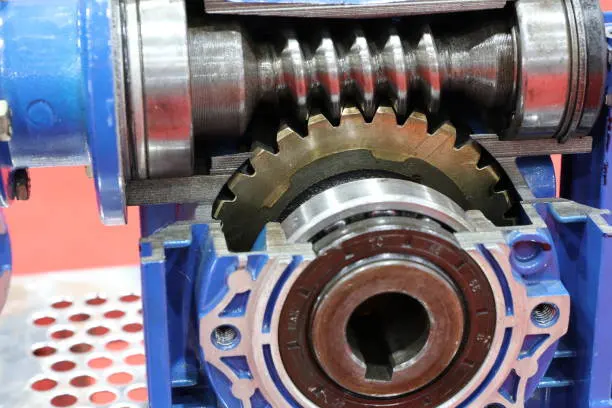

In the manufacturing process of EPRV series small worm gearboxes, heat treatment plays a crucial role in enhancing the performance and durability of the gearboxes. By subjecting the components to controlled heating and cooling processes, heat treatment helps to improve the mechanical properties of the materials used, including hardness, strength, and wear resistance. This article will explore the various aspects of heat treatment and its significance in the manufacturing of EPRV series small worm gearboxes.

1. Importance of Heat Treatment in Gearbox Manufacturing

Heat treatment is a critical step in gearbox manufacturing as it affects the overall performance and quality of the final product. It helps to optimize the material properties to withstand the demanding operating conditions and ensures a longer service life for the gearboxes.

2. Types of Heat Treatment

2.1. Annealing

2.2. Normalizing

2.3. Quenching

2.4. Tempering

2.5. Case Hardening

3. Role of Heat Treatment in EPRV Series Small Worm Gearbox Manufacturing

3.1. Increased Hardness and Strength

3.2. Improved Wear Resistance

3.3. Enhanced Dimensional Stability

3.4. Reduction of Residual Stresses

3.5. Optimization of Microstructure

4. Heat Treatment Process

4.1. Preheating

4.2. Heating

4.3. Soaking

4.4. Cooling

4.5. Tempering

5. Quality Control in Heat Treatment

5.1. Hardness Testing

5.2. Microstructure Analysis

5.3. Dimensional Inspection

5.4. Residual Stress Analysis

5.5. Mechanical Testing

6. Conclusion

In conclusion, heat treatment plays a vital role in the manufacturing of EPRV series small worm gearboxes. It helps to enhance the mechanical properties, improve wear resistance, and ensure dimensional stability of the gearboxes. With proper heat treatment processes and quality control measures, manufacturers can produce high-quality gearboxes that meet the industry standards and provide reliable performance. By integrating heat treatment into the manufacturing process, EPRV series small worm gearboxes can deliver superior functionality and durability in various applications.

Elektrische motoren te koop

Electric motors and gearboxes are complementary components in many industrial applications. The gearbox, such as the EPRV series small worm gearbox, provides the necessary speed reduction and torque multiplication, while the electric motor converts electrical energy into mechanical energy to drive the gearbox. The synergy between the two is essential in achieving efficient and reliable machinery operation.

At our company, we not only offer high-quality EPRV series small worm gearboxes but also provide a range of electric motors for sale. Our electric motors are designed to work seamlessly with our gearboxes, ensuring optimal performance and compatibility. We understand the importance of a reliable power transmission system, and that's why we offer both gearboxes and electric motors to meet our customers' diverse needs.

Over ons

RP Techniek BV is the Netherlands sales agent for Ever-power Group. We are a comprehensive transmission equipment manufacturer with over 25 years of experience in designing, producing, manufacturing, and selling gearboxes. Our reputation spans across Europe, America, Africa, Asia, and other regions.

As a company, we pride ourselves on providing the highest quality products, competitive prices, and excellent customer service. We have established ourselves as a leader in the industry by investing in advanced production and testing equipment, employing industry professionals and technicians, and implementing standardized production management methods.

Our gearboxes are widely used in various industries, including equipment, food, car washing, packaging, transmission, automation, solar energy, and more. We strive to deliver gearboxes that are not only high in quality but also energy-efficient and stable, meeting the demands of our customers and contributing to their success.

We encourage you to explore our products further and contact us for any inquiries or purchases. We are committed to providing the best transmission solutions to support your business.

Vragen en antwoorden

Q1: What materials are commonly used in EPRV series small worm gearboxes?

A1: EPRV series small worm gearboxes are commonly made from materials such as cast iron, steel, and bronze alloys.

Q2: How does heat treatment improve the wear resistance of EPRV series small worm gearboxes?

A2: Heat treatment alters the microstructure of the materials, resulting in increased hardness and improved wear resistance.

Q3: What are the key advantages of using electric motors in combination with EPRV series small worm gearboxes?

A3: Electric motors provide efficient, reliable, and precise power delivery to drive EPRV series small worm gearboxes, ensuring optimal performance and productivity.

Q4: How can customers ensure the compatibility between EPRV series small worm gearboxes and electric motors?

A4: Customers should consult the manufacturer's specifications and recommendations to ensure the proper selection and matching of EPRV series small worm gearboxes and electric motors.

Q5: What are the main factors to consider when choosing EPRV series small worm gearboxes?

A5: The main factors to consider include the required torque, speed ratio, mounting configuration, input/output shaft dimensions, and environmental conditions for the specific application.

Bewerkt door: Zqq.