In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

WPWEKO Series Double Stage Worm Gearboxes

The WPWEKO Series Double Stage Cast Iron Worm Gearbox is composed of transmission parts, worm gear and worm, shaft, bearing, box, and accessories. It has a three essential structure of box, worm gear, worm bearing, and shaft combination. The box supports the fixed shafting parts and ensures the correct relative position of the transmission accessories. The worm gear transfers movement and power between the two staggered shafts, while the bearings and shafts transfer power, run, and improve efficiency.

|

|

Productomschrijving

| Type | wpweko worm speed reducers |

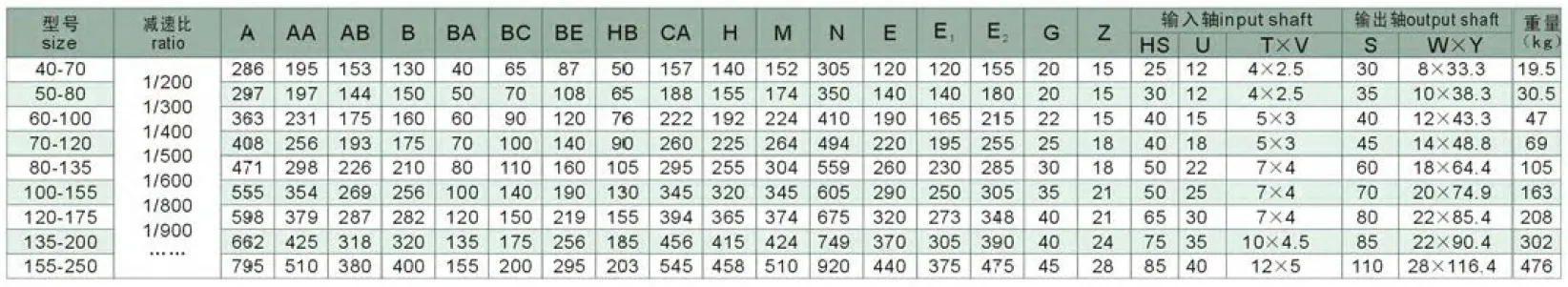

| Size | 40??250 |

| Verhouding | 1:200, 300, 400, 500, 600, 800, 900 |

| Mounting Position | Foot-mounted, flange mounted |

| Output Form | Solid shaft, hollow shaft |

| Material of Housing | Casting Iron |

| Material of Shaft | chromium steel |

| Oil seal | KSK |

| Handelswijze | C&U |

| Certificate | ISO9001 |

| Garantie | One year |

| Features of WPWEKO Series Worm wheel Gearbox | |

| 1. Stable transmission, low impact and noise, large reduction ratio, wide versatility, and suitable for use with various mechanical equipment. | |

| 2. Larger transmission ratio can be obtained by single-stage transmission; most reducers have suitable self-locking properties with compact structures and can save the brake device for mechanical equipment with brake requirements. | |

| 3. The meshing friction loss between worm screw teeth and worm gear surface. And is relatively large, so the transmission efficiency is lower than that of the gear, and it is easy to be heated the temperature is higher. | |

| 4. The worm wheels and shafts are manufactured according to tonal standards. | |

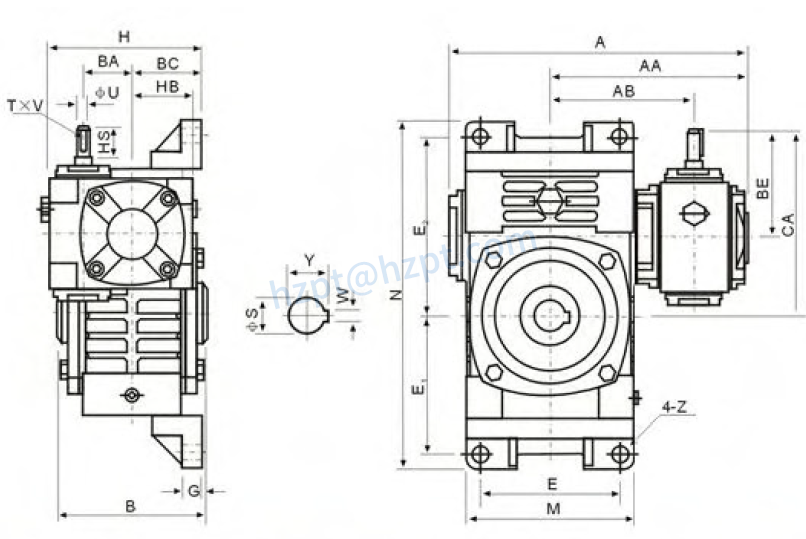

Specifications Parameter

Precautions for the Use of Worm Gearboxes

1. Ensure assembly quality. When disassembling and installing the parts of the reducer, try to avoid knocking with hammers and other devices; when replacing gears, worm gears, and worms, try to use original accessories and replace them in pairs; when assembling the output shaft, pay attention to Tolerance fit; use an anti-sticking agent or red dan oil to protect the hollow shaft to prevent wear and rust or scale on the mating area, which is difficult to disassemble during maintenance.

2. Selection of lubricating oil and additives. Worm gear reducers generally use 220# gear oil. For reducers with heavy loads, frequent starting, and poor use environment, some lubricating oil additives can make the gear oil adhere to the gear surface when the reducer stops running, forming a protective effect. The additive contains a seal ring adjuster and anti-leakage agent, which keeps the seal ring soft and elastic and effectively reduces the leakage of lubricating oil.

3. Selection of the installation location of the reducer. If the location allows, try not to use vertical installation. During vertical installation, the amount of lubricating oil added is much higher than that in horizontal installation, which may easily cause the reducer to heat up and leak oil.

Packing and Transportation

Verpakking: To ensure the integrity of product appearance, we will choose cartons, wooden pallets, and wooden pallets according to customer needs.

Delivery time: Each reducer is manufactured and tested by strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

Transportation mode: Wij kiezen de meest geschikte transportmethode voor onze klanten op basis van het gewicht en de grootte van de goederen. Wij kunnen ook de transportmethode kiezen op basis van de behoeften van onze klanten.

Receiving and after-sales service: Controleer na ontvangst van de goederen of ze in goede staat zijn. Wij zullen klanten een perfecte aftersales service bieden.

Over ons

Ever-power is a comprehensive transmission equipment manufacturer integrating research and development, manufacturing and sales of speed reducers. We have more than 25 years of experience in the design, production, manufacture and sales of gearboxes, serving customers in Europe, America, Africa, Asia, etc., and have won the praise of the market. Our consistent mission and vision over the years, our company has introduced advanced production equipment and testing equipment at home and abroad, employing industry professionals and technicians to carry out innovative research and development and manufacturing, the use of standardized production management methods to strictly control every aspect of the production of reducers, over the years has been to provide customers with high-quality, high-energy-efficiency, high-stability production of crystals. Our gearboxes are widely used in equipment Industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry and so on. Welcome and trust by customers.

Elektrische motoren te koop

Electric motors and gearboxes are closely related and complement each other. Without a gearbox, an electric motor cannot work efficiently, and without an electric motor, a gearbox will not function at all. Our company provides matching electric motors for sale to meet the needs of different customers, ensuring efficient and stable operation of the gearbox. Please feel free to contact us to explore our electric motor products.

Veelgestelde vragen

Q1: What information should I tell you to confirm the iron worm gear speed reducer?

A: Model/Size. B: Ratio and output torque. C: Power and flange type. D: Shaft Direction. E: Housing color. F: Order quantity.

Q2: What type of payment methods do you accept?

A: T/T. B: B/L. C: CASH

Q3: What's your warranty?

One year.

Q4: How to deliver?

A: By sea-Customer appoints a forwarder, or our sales team finds a suitable forwarder for buyers. By air-Customer offers to collect an express account, or our sales team finds a suitable express for the customer. (Mostly for sample) Other-We arranges to deliver goods to some place in China appointed by the customer.

Q5: Can you make OEM order?

Yes, we have rich experience in OEM orders and like signing Non-disclosure Agreements before sample making.

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...