The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

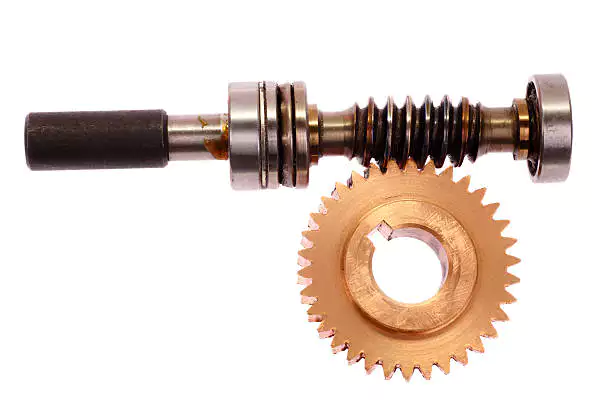

Telescope Worm Gear

The telescope worm gear is a precision-engineered component designed for smooth rotational movement in telescopes. Made from high-quality materials like aluminum or brass, this telescope worm gear set ensures durability and reliability. Its primary function is to allow fine adjustments in the positioning of optical devices, enhancing the user experience in astronomy.

Details of Telescope Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 1:20 |

| Materiaal | Aluminum Alloy |

| Weight | 250g |

| Max Load | 1000N |

| Afmetingen | 150mm x 50mm x 40mm |

| Efficiency | 90% |

Features of Telescope Worm Gear

- Precision Engineering: The telescope worm gear is designed with high precision, ensuring smooth operation and minimal backlash. This allows for accurate positioning in various applications.

- Durability: Made from robust materials, the telescope worm gear set is built to withstand heavy loads and resist wear over time, providing long-lasting performance.

- Versatile Applications: Ideal for telescopes, this gear set is not only used in astronomy but also in various mechanical systems that require reliable torque transmission.

Applications of Telescope Worm Gear in Precision Machinery

The telescope worm gear is an essential component in various precision machinery, offering smooth and reliable motion transfer. This telescope worm gear set is specifically designed to provide high torque and precise control, making it perfect for applications in telescopes, camera mounts, and robotic systems. The unique design ensures minimal backlash and enhanced durability, which are crucial for maintaining accuracy in demanding environments. With its superior engineering, the telescope worm gear set not only optimizes performance but also extends the lifespan of the machinery it operates in. Enhance your projects with the advanced capabilities of the telescope worm gear.

Manufacturing Process of Telescope Worm Gear

- Material Selection: The manufacturing of a telescope worm gear begins with careful selection of high-quality materials. Typically, materials like alloy steel or brass are chosen for their strength and durability, essential for the longevity and performance of the telescope worm gear set. The right material ensures that the gear can withstand the mechanical stresses during operation while providing smooth motion for precision telescopic applications.

- Machining the Worm Shaft: Once the material is selected, the next step is machining the worm shaft. This involves precision cutting, shaping, and grinding to achieve the desired dimensions and profiles. The worm shaft must be manufactured with high accuracy to match the corresponding worm wheel perfectly. Any deviation can lead to inefficiencies and increased wear in the telescope worm gear set, affecting overall performance.

- Worm Wheel Fabrication: Following the worm shaft, the worm wheel is fabricated. This process requires similar precision and detail, as the interaction between the worm and wheel is crucial for effective torque transmission. The mating surfaces must be finely finished to reduce friction and wear. The design and teeth of the worm wheel are critical for ensuring smooth engagement with the telescope worm gear, facilitating optimal performance in telescopic mechanisms.

- Heat Treatment: After machining, both the worm shaft and worm wheel undergo heat treatment processes. This includes hardening and tempering to enhance the mechanical properties of the telescope worm gear components. Heat treatment increases hardness and toughness, which are vital for reducing wear and extending the life of the telescope worm gear set under load conditions.

- Assembly and Quality Control: The final steps involve assembling the telescope worm gear components and conducting rigorous quality control tests. Each telescope worm gear set is inspected for precision, compatibility, and functionality. This step is crucial to ensure that the assembled gear operates smoothly and meets the required specifications, ensuring reliable performance in its application.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands and is proud to be one of the top ten worm gear suppliers in the country.

Our product range includes high-quality Telescope Worm Gears, characterized by:

- Superior Quality: Our worm gears are manufactured using top-grade materials, ensuring durability and performance.

- Exceptional Precision: Each product is engineered to provide reliable and accurate motion control, making them suitable for various applications.

- Strong Industry Presence: With years of experience and expertise, we have established a strong reputation in the market.

- Outstanding Customer Service: Our dedicated team is committed to providing excellent support and service to our clients.

Aanvullende informatie

| Edited | Zqq |

|---|

Blogs bijgewerkt

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...