The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Small Worm Gears

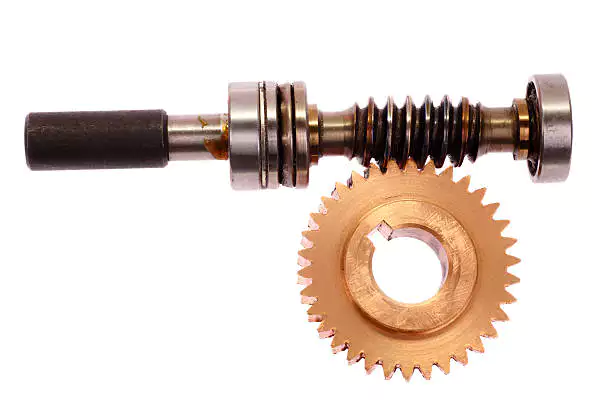

Small worm gears are precision-engineered components designed for efficient power transmission in compact applications. Made from high-quality materials such as brass or steel, these mini worm gears offer durability and reliability. Ideal for robotics and automation, miniature worm gears provide smooth operation and can be found in various miniature worm gear sets for versatile use.

Details of Small Worm Gears

| Parameter | Value |

|---|---|

| Materiaal | Aluminum Alloy |

| Gear Ratio | 10:1 |

| Diameter | 20 mm |

| Max Load | 100 N |

| Efficiency | 85% |

| Temperature Range | -20 to 100 °C |

Features of Small Worm Gears

- Compact Design: Small worm gears are designed to fit into tight spaces, making them ideal for applications where size is a constraint. Their mini worm gear counterparts offer even smaller dimensions, perfect for miniature devices.

- High Torque Transmission: These gears provide excellent torque transmission, ensuring effective power transfer in various mechanical systems. Miniature worm gear sets are particularly beneficial for small-scale machinery requiring robust performance.

- Smooth Operation: Small worm gears are engineered for smooth and quiet operation, reducing noise in devices. This characteristic is crucial for applications in electronics and precision instruments.

How Small Worm Gears Work

Small worm gears are essential components in various mechanical systems, providing efficient torque transmission in a compact size. These mini worm gears operate by engaging the worm, which is a screw-like gear, with a worm wheel. This unique design allows for a high gear reduction ratio, making miniature worm gears ideal for applications requiring precise control and high torque. Whether in robotics or small machinery, miniature worm gear sets offer reliable performance while saving space. For a closer look at these components, check out the image below:

Manufacturing Process of Small Worm Gears

- Design and Engineering: The manufacturing process of small worm gears begins with detailed design and engineering. Engineers utilize advanced CAD software to create precise models of miniature worm gears. This stage focuses on optimizing gear ratio, strength, and efficiency. The design must ensure compatibility with mini worm gear systems, as even minor inaccuracies can lead to performance issues. Careful calculations are made to determine the dimensions and materials best suited for the intended application, whether it's in robotics, automotive, or other machinery. Proper design is crucial for achieving high-quality miniature worm gear sets.

- Material Selection: Selecting the right material is vital in the manufacturing of small worm gears. Typically, high-strength materials like steel or aluminum alloys are chosen for their durability and resistance to wear. Certain applications may require plastic materials for lightweight designs. The choice impacts the performance, lifespan, and cost-effectiveness of the mini worm gear. The process involves analyzing factors such as load capacity, environmental conditions, and production costs to ensure that the selected material meets all requirements for the miniature worm gears.

- CNC Machining: CNC (Computer Numerical Control) machining is employed to achieve the precise dimensions of small worm gears. This process ensures that each component is manufactured with high accuracy and consistency. CNC machines are programmed to cut, shape, and finish the miniature worm gears to the exact specifications of the design. This technology allows for the production of intricate profiles necessary for the proper engagement between the worm and the wheel in miniature worm gear sets. The precision of CNC machining significantly reduces manufacturing errors and enhances the overall quality of the end product.

- Heat Treatment: After machining, small worm gears often undergo heat treatment to improve their mechanical properties. This process involves heating the gears to a specific temperature and then cooling them rapidly. Heat treatment enhances the hardness and strength of the materials used in the mini worm gears, ensuring they can withstand high loads and friction during operation. This step is critical in extending the lifespan of miniature worm gear sets, making them suitable for demanding applications in various industries.

- Finishing Processes: The final stage in the manufacturing process involves various finishing techniques, including grinding, polishing, and coating. These processes are essential for achieving the desired surface finish and dimensional accuracy of small worm gears. A smooth surface reduces friction and wear, enhancing the efficiency of mini worm gear systems. Additionally, coatings may be applied to improve corrosion resistance and reduce maintenance requirements. Thorough inspection and testing follow these processes to ensure all miniature worm gears meet quality and performance standards.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands. Our company specializes in small worm gears, providing high-quality products that meet the demands of various industries.

- **Quality and Excellence**: We pride ourselves on delivering products that are manufactured to the highest standards, ensuring reliability and durability in every application.

- **Strength and Capability**: Our extensive experience in the industry allows us to offer robust solutions tailored to our customers' specific needs.

- **Comprehensive Service**: We are committed to providing exceptional customer service, guiding clients through the selection process and ensuring timely delivery.

Aanvullende informatie

| Edited | Zqq |

|---|

Blogs bijgewerkt

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...