The worm shaft plays a vital role in worm gear transmission systems, finding extensive use across industries like machinery, motors, and heavy equipment. Its performance hinges on precision, durability, and wear resistance, making the manufacturing process critical to...

Metal Worm Gear

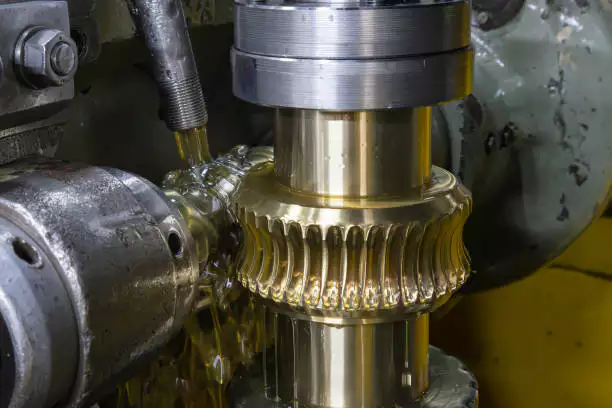

The metal worm gear is a crucial mechanical component used for transmitting torque and motion between non-parallel shafts. Made from high-quality metal, this durable product ensures long-lasting performance. A metal worm gear set can provide precise speed reduction and increased torque, making it ideal for various applications in machinery and equipment.

Details of Metal Worm Gear

| Parameter | Value |

|---|---|

| Materiaal | Steel |

| Size | Customizable |

| Pitch Diameter | Varies |

| Tooth Count | 10-100 |

| Load Capacity | High |

| Sollicitatie | Automotive, Machinery |

Features of Metal Worm Gear

- High Strength and Durability: Metal worm gears are designed to withstand heavy loads and resist wear over time, ensuring long-lasting performance. This quality is essential for industrial applications where reliability is critical.

- Precision Engineering: The metal worm gear set is manufactured with high precision, providing smoother operation and improved efficiency. This precision reduces friction, leading to lower energy consumption and increased lifespan.

- Compact Design: Metal worm gears offer a compact solution for power transmission, making them ideal for applications with limited space. Their design allows for high torque in a small footprint.

How Metal Worm Gears Function

The metal worm gear operates on the principle of a screw mechanism, where a rotating worm interacts with a gear, providing efficient torque transfer and speed reduction. This metal worm gear set is designed for high precision and durability, making it ideal for various applications such as conveyors, robotics, and automotive systems. The unique design minimizes backlash and enhances performance, ensuring smooth operation. With its robust construction, the metal worm gear is capable of handling substantial loads, offering reliable functionality in demanding environments.

Manufacturing Process of Metal Worm Gear

- Material Selection: The production of a metal worm gear begins with selecting high-quality materials that ensure durability and strength. Typically, materials such as steel or bronze are chosen for their robustness and wear resistance. The selected metal is then analyzed for its properties to ensure it meets the specific requirements of the application for which the metal worm gear set is intended. This careful selection process is crucial as it impacts the performance and longevity of the gear.

- CNC Machining: Once the materials are ready, CNC (Computer Numerical Control) machining is employed to shape the metal worm gear with precision. This process involves using automated tools to cut and form the metal into the desired shape. The CNC machines ensure that the specifications are met with high accuracy, resulting in a finely crafted metal worm gear. The precise machining is essential for the smooth operation of the gear set, minimizing friction and enhancing performance.

- Heat Treatment: After machining, the metal worm gear undergoes heat treatment to improve its hardness and wear resistance. This involves heating the gear to a specific temperature and then cooling it rapidly, which alters the microstructure of the metal, making it stronger and more durable. Heat treatment is a critical step in the manufacturing process as it ensures that the metal worm gear can withstand the stress and pressure it will face during operation.

- Finishing Processes: The final step involves various finishing processes such as grinding, polishing, and coating. These processes enhance the surface quality of the metal worm gear, ensuring smooth operation and reducing friction. Additionally, protective coatings may be applied to prevent corrosion and extend the lifespan of the metal worm gear set. A well-finished gear not only improves performance but also contributes to the overall aesthetics of the product.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top ten worm gear suppliers in the Netherlands.

Our company specializes in Metal Worm Gears, offering a range of products that meet the highest industry standards:

- Exceptional Quality: Our worm gears are manufactured using premium materials, ensuring durability and performance.

- Top-notch Craftsmanship: Each product undergoes rigorous quality control to guarantee precision and reliability.

- Strong Expertise: With years of experience, we possess the technical know-how to provide tailored solutions for various applications.

- Outstanding Customer Service: Our dedicated team is committed to understanding client needs and delivering exceptional support throughout the purchasing process.

Aanvullende informatie

| Edited | Zqq |

|---|

Blogs bijgewerkt

How Does the Transmission Chain in Holland Affect the Efficiency of Industrial Machinery?

In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...