In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

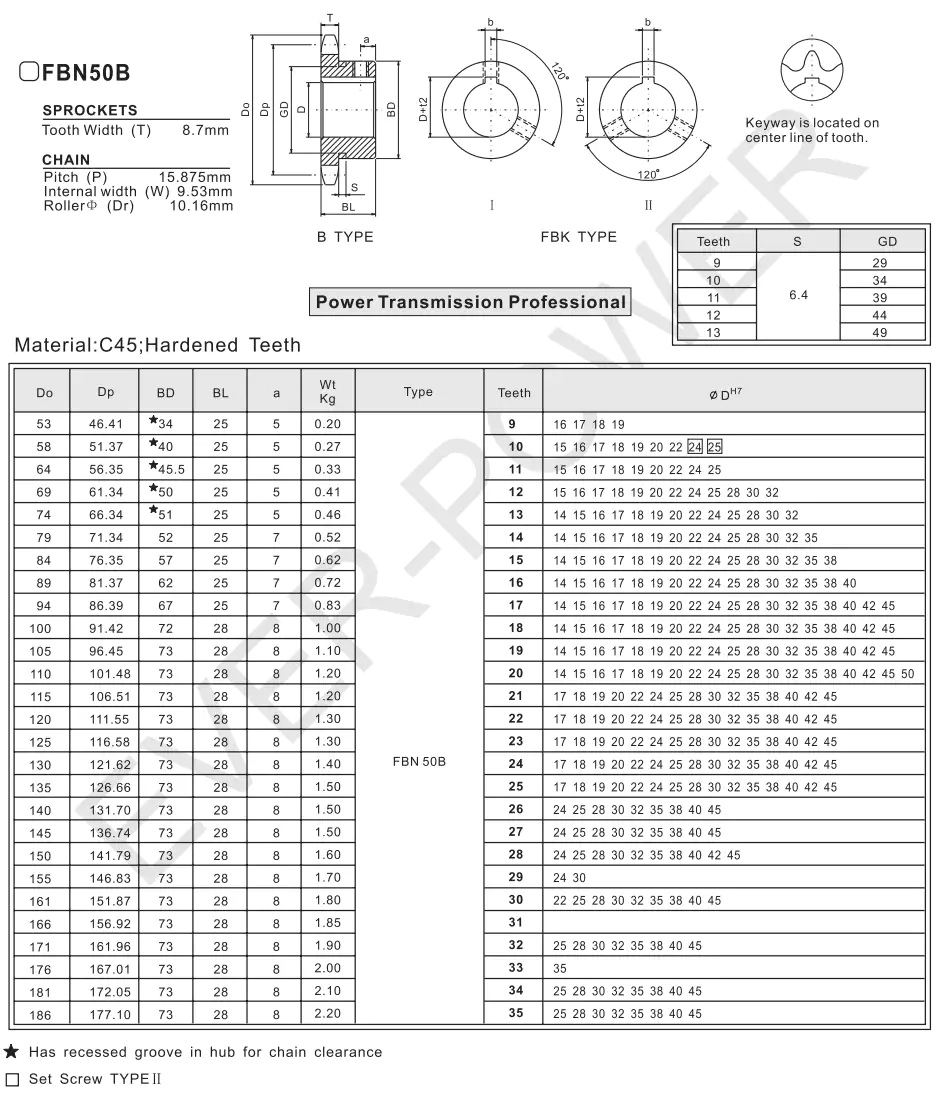

FBN50B Finished Bore Sprocket

The FBN50B Finished Bore Sprocket is designed for high-performance applications, ensuring durability and precision in power transmission. Crafted from high-quality materials, it features a finished bore for easy installation on various shafts. Ideal for industrial machinery and conveyor systems, this sprocket enhances efficiency and reliability in your operations.

Specifications of FBN50B Asian Standard Finished Bore Sprocket

A finished bore sprocket is a specialized type of sprocket that comes with a pre-bored hole. This design makes it incredibly easy to install onto a shaft, eliminating the need for any additional machining processes. Such sprockets are extensively utilized in various power transmission systems, efficiently facilitating the transfer of rotary motion between two separate shafts.

Materials and Manufacturing Process

Materialen

The finished bore sprockets can be manufactured from a variety of materials, including high carbon steel, alloy steel, or stainless steel. The choice of material is influenced by the specific requirements and constraints of the application in which the sprocket will be used, ensuring optimal performance and durability.

Manufacturing Process

The manufacturing of finished bore sprockets involves several critical stages to ensure quality and precision:

- Material selection and cutting

- Punching or forging to shape the sprocket

- Machining processes such as turning, milling, and drilling to achieve exact dimensions

- Heat treatment techniques, including quenching, tempering, and surface hardening, to enhance strength

- Surface treatment methods to prevent rust and corrosion

- Rigorous quality inspection to ensure that all specifications are met

Applications of Finished Bore Sprocket

Finished bore sprockets serve a vital role in numerous industries, including:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical sectors

- Assembly lines

- Logistics and warehousing operations

Maintenance and Care

To guarantee the optimal performance and longevity of the sprocket, regular maintenance is essential. The following steps should be incorporated into a maintenance routine:

- Conduct daily inspections for any signs of damage or wear

- Clean the sprocket thoroughly to remove accumulated dirt and debris

- Lubricate the sprocket periodically to reduce friction and prevent corrosion

- Adjust and calibrate the sprocket to maintain the correct tension

Common issues that may arise with sprockets include tooth jumping, breakage, wear, excessive noise, and chain slippage. To effectively address these issues:

- For tooth jumping, ensure the alignment and tension of the chain are correct

- In case of a breakage, promptly replace the damaged sprocket

- Regular lubrication and proper maintenance can significantly reduce wear

- Excessive noise can often be mitigated by adjusting tension and applying lubricant

- If chain slippage occurs, it’s important to check the tension and make necessary adjustments

Other Types of Sprockets

In addition to finished bore sprockets, RP Techniek BV also offers a comprehensive range of other sprocket types, such as taper lock sprockets, QD sprockets, idler sprockets, and more. We provide a variety of chains to complement our sprockets effectively.

Sprockets Supplier in the Netherlands

RP Techniek BV serves as a dedicated sales agent for Ever-power Group in the Netherlands, focused on delivering high-quality power transmission solutions. Our standout product is the FBN50B Asian Standard Finished Bore Sprocket, designed with precision and durability. This sprocket is ideal for various applications in industrial machinery and automotive sectors. All of our products are manufactured in compliance with industry standards, ensuring reliability and top-notch performance.

Alongside standard sprockets, we also specialize in custom non-standard sprocket solutions tailored to fulfill specific customer needs. We encourage all customers to reach out with their designs or samples for personalized manufacturing options.

Aanvullende informatie

| Edited | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...