In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications

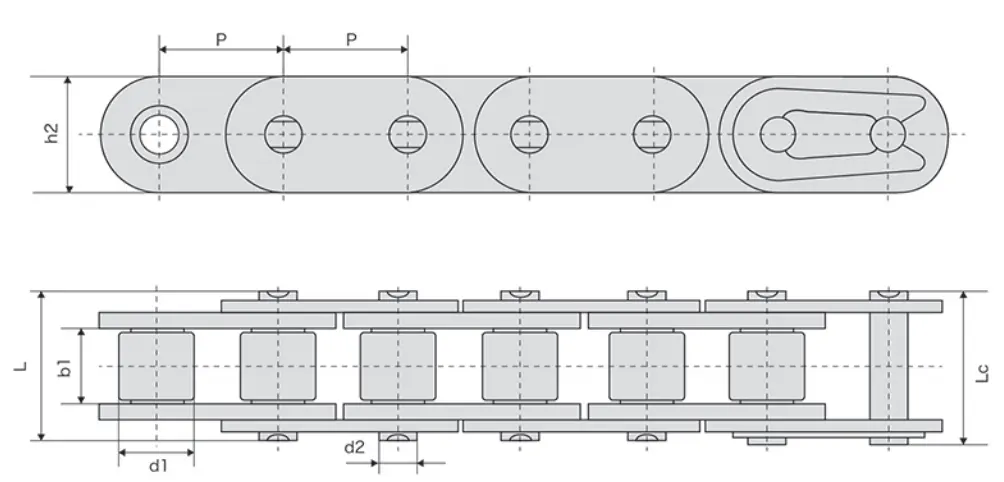

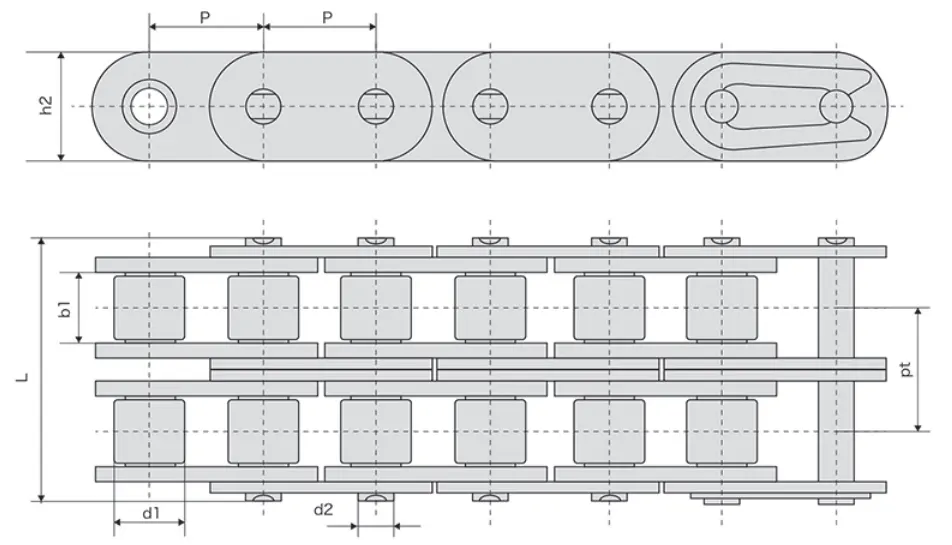

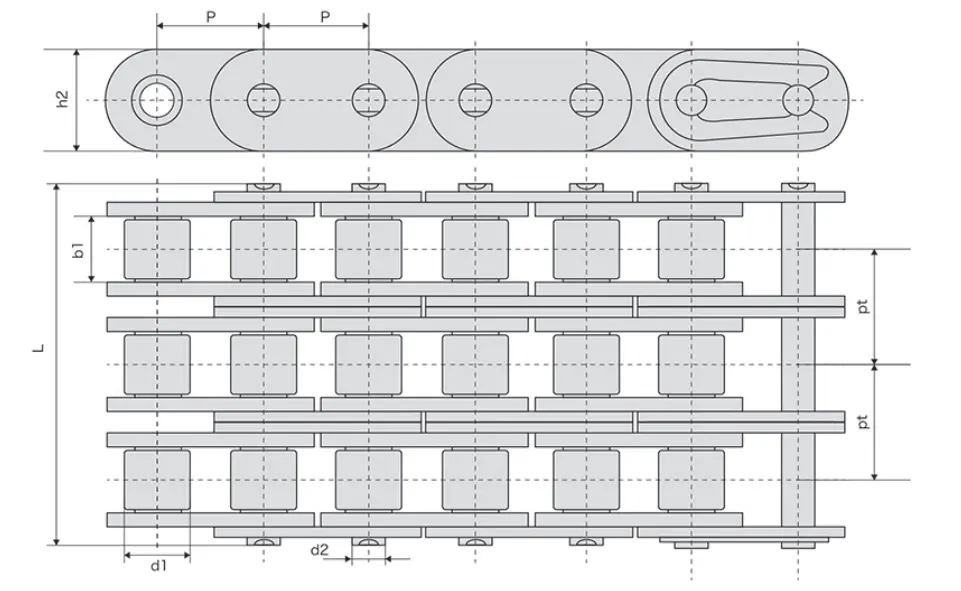

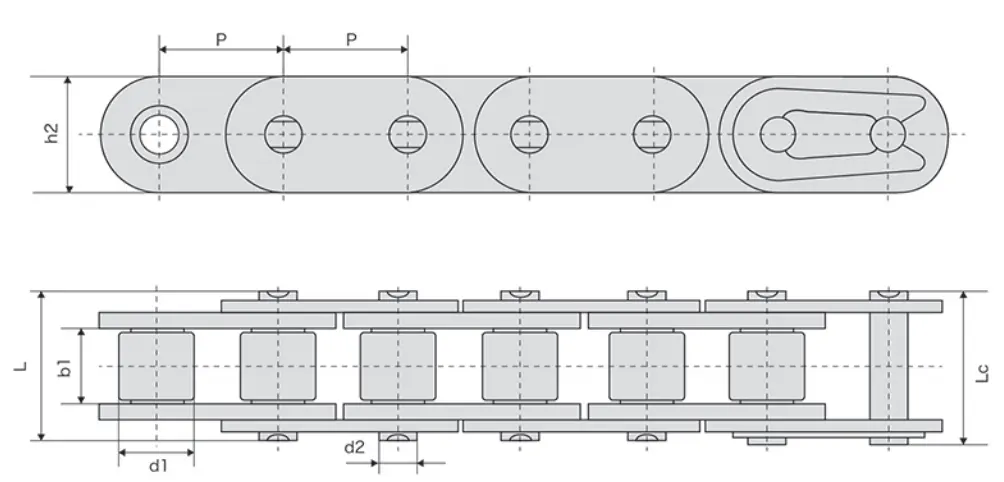

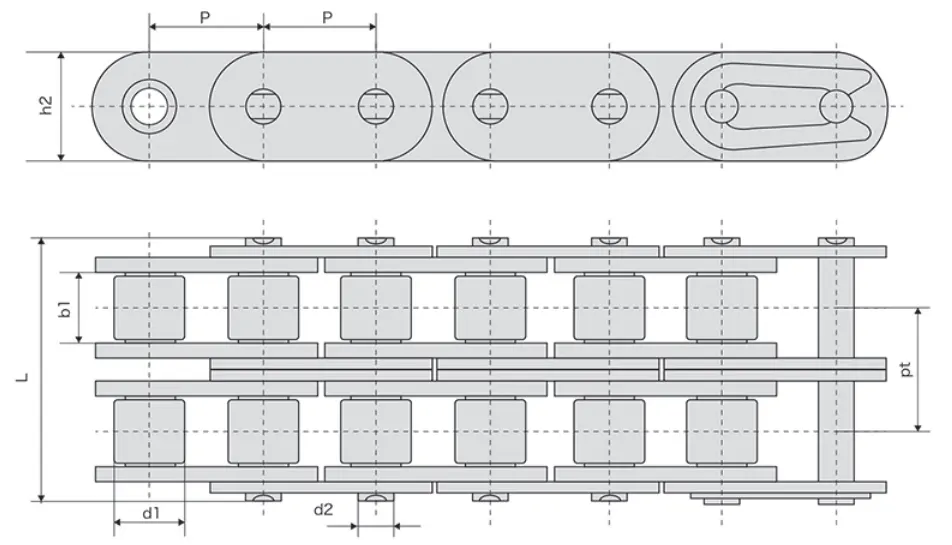

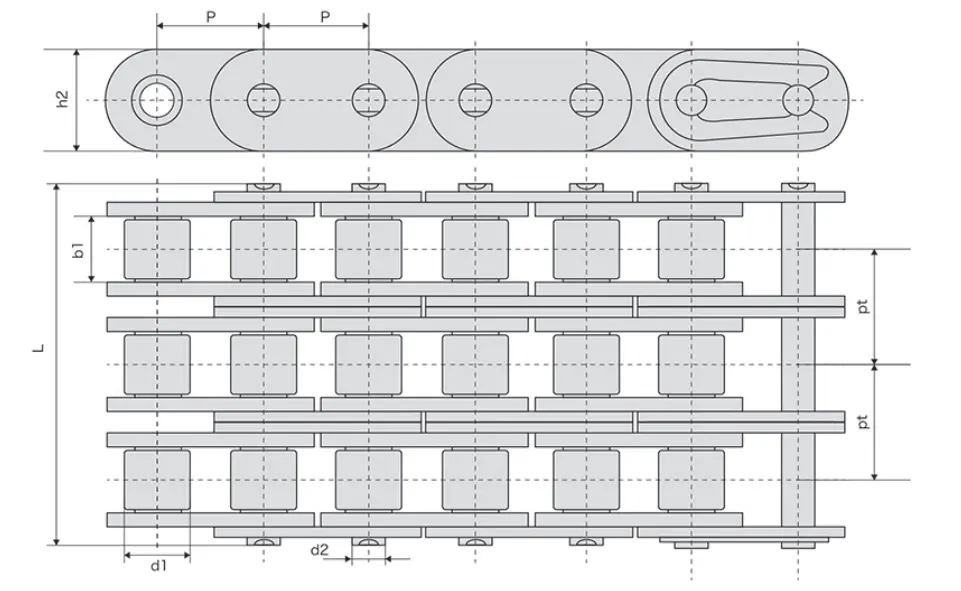

The C80SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates has the following parameters:

| DIN ISO Chain No. | DIN ISO Chain No. | Toonhoogte | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

| Chain No. | Toonhoogte | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 maximaal |

bl mijn |

d2 maximaal |

Ik maximaal |

h2 maximaal |

Q mijn |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

| Chain No. | Toonhoogte | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 maximaal |

bl mijn |

d2 maximaal |

Ik maximaal |

h2 maximaal |

Pt | Q mijn |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Invoering

The C80SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality chain designed for use in harsh environments, such as those found in the food and drink processing industry, the pharmaceutical industry, and the chemical industry.

Ontwerp

The chain is made from duplex stainless steel, which is a material known for its excellent resistance to corrosion, high strength, and good weldability. The chain is designed with straight side plates that provide a more uniform bearing surface for the rollers, which helps to reduce wear and prolong the life of the chain.

Features

Corrosion Resistance

The C80SS-2 Duplex Stainless Steel Roller Chain is highly resistant to corrosion, making it ideal for use in harsh environments where traditional chains would quickly deteriorate. The duplex stainless steel material is resistant to pitting and crevice corrosion, as well as stress corrosion cracking.

Strength

The chain is made from high-strength duplex stainless steel, which gives it excellent strength and durability. This makes it suitable for use in heavy-duty applications where high loads are present.

Weldability

Duplex stainless steel is known for its good weldability, which makes it easier to weld the chain together when required. This is important for applications where the chain needs to be custom-fit to a specific length.

Lubrication

The C80SS-2 Duplex Stainless Steel Roller Chain requires regular lubrication to ensure smooth operation and to prevent wear. It is recommended to use a high-quality lubricant that is compatible with duplex stainless steel.

Temperature Resistance

The chain is designed to withstand high temperatures, making it suitable for use in applications where heat is present. It can operate in temperatures ranging from -20¡ãC to 200¡ãC.

Applications

The C80SS-2 Duplex Stainless Steel Roller Chain is suitable for use in a wide range of applications, including:

- Food and drink processing

- Pharmaceuticals

- Chemicals

- Pulp and paper

- Oil and gas

Conclusion

The C80SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a highly durable and corrosion-resistant chain that is suitable for use in a wide range of applications. Its high strength, good weldability, and temperature resistance make it an ideal choice for heavy-duty and high-temperature applications. Regular lubrication is required to ensure smooth operation and to prolong the life of the chain.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the Netherlands sales agent of Ever-power Group, known for its high-quality products and exceptional services worldwide. Our company takes pride in offering C80SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates - a product that stands out from the rest because of its unique features.

Our stainless steel roller chains are engineered to provide maximum strength, durability, and reliability even in extreme environments. We use premium quality materials and advanced manufacturing techniques to ensure our products meet the highest standards of quality and performance.

Apart from C80SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, we also offer a wide range of other types of stainless steel roller chains for sale. All our products are designed to meet the diverse needs of our customers, and our team of experts is always available to provide the necessary guidance and support.

At RP Techniek BV, we are committed to delivering superior quality products, exceptional services, and competitive prices to our customers. Our state-of-the-art production facilities and experienced team of professionals allow us to meet the demands of our customers efficiently.

Sprockets for Sale

When it comes to finding the perfect match for the C80SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, look no further. Our company offers a wide range of different types of sprockets that are suitable for this chain. Whether you need a standard sprocket, a custom-designed one, or a special type for specific applications, we have you covered.

Our sprockets are made from high-quality materials to ensure durability and reliability. They are precisely engineered and manufactured to provide a seamless fit with the C80SS-2 chain, offering smooth operation and efficient power transmission.

With our extensive inventory, you can find sprockets in various sizes, tooth counts, and designs to meet your specific requirements. We provide options for different shaft diameters and bores, allowing for easy installation and compatibility with different machinery.

At our company, we understand the importance of offering a diverse range of sprockets to cater to various industries and applications. From industrial machinery to agricultural equipment, our sprockets are suitable for a wide array of uses. We also provide sprockets for different environments, including those that require corrosion resistance or high temperature tolerance.

For more information about our sprockets and to explore our complete product catalog, please visit our website or contact our sales team. We are dedicated to providing top-quality sprockets that meet your specific needs and exceed your expectations.

Aanvullende informatie

| Editor | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...