In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications

- Chain Type: Stainless Steel Hollow Pin Chain

- Model Number: 80HPSS

- Chain Pitch: 1 inch

- Pin Diameter: 0.25 inches

- Breaking Load: 6,840 pounds

- Weight per Foot: 2.6 pounds

| Ketting No |

Toonhoogte | Bush? diameter | Breedte between binnenplaten |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner bord diepte |

Bord dikte |

Breken Laden |

Weight per meter |

Type |

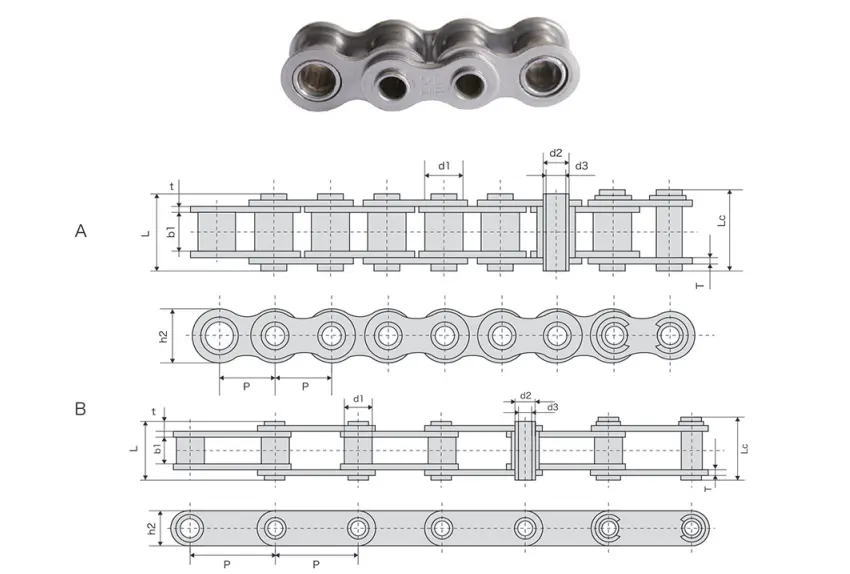

| P | d1 | bl | d2 | d3 | Ik | LC | h2 | T | Q | q | ||

| maximaal | mijn | maximaal | mijn | maximaal | maximaal | maximaal | maximaal | mijn | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

1. Overview

The 80HPSS Stainless Steel Hollow Pin Chain is a high-performance chain designed for various industrial applications. With its unique hollow pin design and stainless steel construction, this chain offers exceptional durability, strength, and corrosion resistance.

2. Features

- Hollow Pin Design: The hollow pin construction allows for easy installation and removal of attachments, providing flexibility in adapting to different applications.

- Stainless Steel Material: Made from high-quality stainless steel, this chain offers excellent resistance to corrosion, chemicals, and extreme temperatures.

- High Strength: The 80HPSS chain has a high tensile strength, ensuring reliable performance even under heavy loads and harsh operating conditions.

- Smooth Operation: The precision engineering of this chain ensures smooth and quiet operation, minimizing friction and wear.

- Wide Range of Applications: This chain is suitable for use in industries such as food processing, packaging, pharmaceuticals, and more.

3. Specifications

The 80HPSS Stainless Steel Hollow Pin Chain meets the following specifications:

- Chain Pitch: 80 (1 inch)

- Material: Stainless Steel

- Pin Type: Hollow Pin

- Working Load Capacity: Varies depending on the specific application

- Operating Temperature Range: -40¡ãC to +200¡ãC

4. Installation and Maintenance

Proper installation and regular maintenance are crucial for maximizing the performance and lifespan of the 80HPSS Stainless Steel Hollow Pin Chain. It is recommended to follow the manufacturer's guidelines and consider the following:

- Ensure proper tensioning of the chain to prevent excessive wear and elongation.

- Regularly inspect and clean the chain to remove any debris or contaminants that may affect its performance.

- Lubricate the chain with a suitable lubricant to reduce friction and enhance its longevity.

- Replace any worn-out or damaged components promptly to avoid potential chain failure.

5. Safety Precautions

When working with the 80HPSS Stainless Steel Hollow Pin Chain, it is essential to prioritize safety. Follow these precautions:

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Avoid placing hands or fingers near moving chain components to prevent injury.

- Ensure the chain is properly secured and tensioned before operation.

- Follow proper lockout/tagout procedures when performing maintenance or repairs.

For more detailed information regarding installation, maintenance, and safety, please refer to the product manual or consult with our technical support team.

Choose Our Stainless Steel Roller Chains

RP Techniek BV, as the Netherlands sales agent of Ever-power Group, proudly presents our premium stainless steel roller chains. We specialize in the distribution of the 80HPSS Stainless Steel Hollow Pin Chain, which showcases our exceptional selling points and highlights the superior quality and services we offer. Our company takes pride in its robust manufacturing capabilities.

Moreover, we provide a wide range of other stainless steel roller chains to meet diverse industry needs. Our extensive selection ensures that customers can find the perfect chain for their specific requirements.

Please refer to the following image showcasing our stainless steel roller chains:

Sprockets for Sale

When it comes to finding the perfect match for your 80HPSS Stainless Steel Hollow Pin Chain, look no further than our wide selection of sprockets. At our company, we offer a variety of different types of sprockets for sale to meet your specific needs.

Our sprockets are designed with precision and durability in mind, ensuring optimal performance and longevity. Whether you require a standard sprocket or a custom-made one, we have got you covered.

With our extensive inventory, you can choose from various sizes, tooth counts, and materials to find the ideal sprocket for your application. Our knowledgeable team is also available to assist you in selecting the right sprocket for your specific requirements.

Aanvullende informatie

| Editor | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...