In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

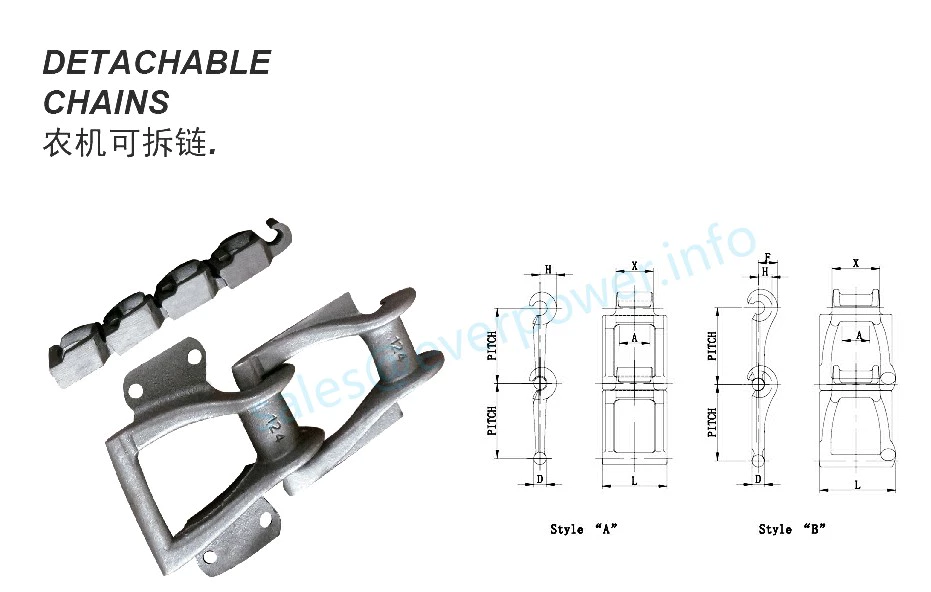

Specifications for 75 Casting Detachable Chain

- Size: 75

- Type: Casting Detachable

- Material: Steel

- Working Load Limit: 5,000 lbs

- Pitch: 3 inches

- Pin Diameter: 0.75 inches

- Overall Width: 1.75 inches

| CHAIN NO. | PITCH IN INCHES |

HEIGHT PER FOOT LBS |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | ?F | H | ?L | X | AVAILABLE ATTACHMENTS |

| 25 | 0.902 | 2.4 | 700 | 120 | 0.38 | 0.14 | ¡ª¡ª | 0.20 | ?0.78 | 0.41 | A1-R.A1-L | ||

| 32 | 1.154 | 3.5 | 1,100 | 185 | 0.50 | 0.17 | ¡ª¡ª | 0.25 | ?0.97 | 0.58 | A1-R.A1-L.K1 | ||

| 34 | 1.398 | 4.0 | 1.300 | 220 | 0.50 | 0.19 | 1.25 | 0.56 | None | ||||

| 42 | 1.375 | 5.5 | 1.600 | 270 | 0.62 | 0.22 | ¡ª¡ª | 0.28 | 1.28 | 0.77 | A1-R,A1-L.K1 | ||

| 45 | 1.630 | 5.2 | 1.700 | 285 | 0.69 | 0.22 | ¡ª¡ª | 0.30 | ?1.31 | 0.80 | A1-R.A1-L.K1 | ||

| 50 | 1.381 | 7.1 | 1.900 | 320 | 0.63 | 0.27 | 0.33 | ?1.31 | 0.62 | None | |||

| 51 | 1.155 | 7.0 | 1.900 | 320 | 0.56 | 0.27 | ¡ª¡ª | 0.36 | ?1.25 | 0.67 | K1 | ||

| S51 | 1.136 | 7.B | 1.900 | 315 | 0.56 | 0.27 | ¡ª¡ª | 0.30 | ?1.06 | 0.64 | None | ||

| 52 | 1.506 | 8.0 | 2,300 | 385 | 0.62 | 0.27 | ¡ª¡ª | 0.34 | ?1.53 | 0.83 | A1.D5,K1 | ||

| 55 | 1.631 | 7.2 | 2,300 | 385 | 0.69 | 0.27 | ¡ª¡ª | 0.36 | ?1.41 | 0.81 | A1-R/L,D5-R/L,C1.F2,G27-R/L,K1,C | ||

| 57 | 2.308 | 8.7 | 2.900 | 485 | 0.75 | 0.27 | ¡ª¡ª | 0.41 | ?1.81 | 1.09 | A1-R,A1-L.F2 | ||

| 62 | 1.654 | 10.6 | 3.200 | 535 | 0.81 | 0.31 | 0.41 | ?1.66 | 0.97 | A1-R/L,A12-R/L,05-R/L.K1,K2,F2 | |||

| 67 | 2.308 | 8.6 | 2.900 | 485 | 0.69 | 0.31 | ?0.53 | 0.41 | ?2.03 | 1.36 | None | ||

| 75 | 2.609 | 13.4 | 4,100 | 690 | 0.94 | 0.41 | ¡ª¡ª | 0.44 | ?2.09 | 1.12 | D5-R.D5-L | ||

| 77 | 2.297 | 14.5 | 3.600 | 600 | 0.69 | 0.39 | ?0.61 | 0.36 | ?2.22 | 1.42 | A1-R.A1-L.D5.F2,K1 | ||

| 78 | 2.609 | 18.8 | 5.500 | 920 | 0.94 | 0.42 | ?0.66 | 0.44 | ?2.62 | 1.62 | K1 | ||

| 88 | 2.609 | 24.0 | 6.400 | 1,070 | 0.94 | 0.48 | ?0.78 | 0.44 | ?2.75 | 1.78 | F2.K1 | ||

| 103 | 3.075 | 40.0 | 10,000 | 1,670 | 1.12 | 0.58 | ?1.00 | 0.61 | ?3.28 | 2.03 | F2.F8,K1,K2,F2 | ||

| 114 | 3.250 | 53.0 | 12.000 | 2.000 | 1.13 | 0.66 | ?0.17 | 0.81 | ?3.28 | 2.03 | None | ||

| 124 | 4.063 | 66.0 | 17.000 | 2,830 | 1.25 | 0.77 | ?1.31 | 0.68 | ?4.06 | 2.31 | F8.K1,K2 |

1: What is the 75 Casting Detachable Chain?

The 75 Casting Detachable Chain is a versatile and innovative product designed for various industrial applications. It is known for its exceptional durability and detachability, making it an essential component in many manufacturing processes.

2: Key Features of the 75 Casting Detachable Chain

1. Enhanced Strength: The 75 Casting Detachable Chain is constructed using high-quality materials and advanced casting techniques, resulting in superior strength and resistance to wear and tear.

2. Easy Detachability: With its unique detachable design, this chain allows for quick and hassle-free disassembly, enabling efficient maintenance and replacement.

3. Wide Compatibility: The 75 Casting Detachable Chain is compatible with various industrial systems and equipment, making it suitable for diverse applications in sectors such as manufacturing, mining, and logistics.

3: Applications of the 75 Casting Detachable Chain

The 75 Casting Detachable Chain finds extensive use in a range of industries due to its exceptional performance and adaptability. Some common applications include:

- Conveyor Systems: This chain is ideal for conveying heavy loads in industries such as mining, construction, and automotive manufacturing.

- Industrial Machinery: It is widely used in machinery and equipment like hoists, cranes, and agricultural machinery, ensuring smooth and reliable operation.

- Food Processing: The 75 Casting Detachable Chain is also suitable for food processing applications, thanks to its corrosion resistance and hygienic design.

4: Maintenance and Longevity

To maximize the lifespan and performance of the 75 Casting Detachable Chain, regular maintenance is crucial. Here are some tips to ensure its longevity:

- Lubrication: Apply high-quality lubricants to reduce friction and wear between the chain components.

- Inspection: Regularly inspect the chain for any signs of damage or wear, and replace worn-out parts promptly.

- Cleaning: Keep the chain clean from dirt, debris, and contaminants that may cause premature deterioration.

5: Safety Considerations

When using the 75 Casting Detachable Chain, it is important to prioritize safety. Here are some safety considerations to keep in mind:

- Proper Installation: Follow the manufacturer's guidelines for correct installation to ensure optimal performance and prevent accidents.

- Protective Gear: Wear appropriate protective gear, such as gloves and safety glasses, when handling or maintaining the chain to minimize the risk of injuries.

- Load Capacity: Adhere to the recommended load capacity of the chain to prevent overloading, which can lead to failure or accidents.

6: Conclusion

The 75 Casting Detachable Chain is a reliable and versatile product that offers exceptional durability, easy detachability, and wide compatibility. Whether used in conveyor systems, industrial machinery, or food processing, this chain provides optimal performance and contributes to enhanced productivity in various industries. By following proper maintenance procedures and considering safety precautions, users can ensure its longevity and enjoy the benefits it brings to their operations.

Choose Our Malleable Casting Chains

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. As a leading manufacturer of malleable casting chains, our 75 Casting Detachable Chain is a prime example of our unique selling point. Our chains are crafted from high-quality materials and constructed with precision, providing a durable and reliable solution for a variety of applications.

At RP Techniek BV, we take pride in the quality of our products and services. Our malleable cast iron chains are designed to withstand even the most demanding conditions, ensuring maximum uptime and minimal maintenance requirements. In addition, our team of experts is dedicated to providing exceptional customer service, from product selection to after-sales support.

Our production capabilities are second to none. We leverage the latest technologies and manufacturing processes to produce high-quality casting chains that meet or exceed industry standards. This allows us to offer our customers a wide range of casting chains to choose from, including conveyor chains, leaf chains, and roller chains, among others.

At RP Techniek BV, we understand that our customers have unique needs and requirements. That's why we offer custom solutions tailored to your specific needs. Whether you need a standard casting chain or a custom-made solution, we have the knowledge, expertise, and resources to meet your needs.

Take advantage of our commitment to quality and service by choosing RP Techniek BV for your malleable casting chain needs. Contact us today to learn more about our products and services.

Sprockets for Sale

When it comes to pairing with the 75 Casting Detachable Chain, we offer a wide range of suitable sprockets for your needs. Our company provides various types of sprockets for sale, ensuring that you find the perfect match for your application.

Whether you require standard sprockets, taper lock sprockets, or custom-designed sprockets, we have you covered. Our sprockets are made from high-quality materials to ensure durability and reliable performance.

With our extensive selection, you can choose from different sizes, tooth counts, and configurations to meet your specific requirements. Whether you are in the industrial, agricultural, or automotive sector, we have the right sprocket solution for you.

Take a look at the image below for a glimpse of our sprocket offerings:

Contact us today to explore our complete range of sprockets and find the perfect fit for your application.

Aanvullende informatie

| Editor | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...