In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

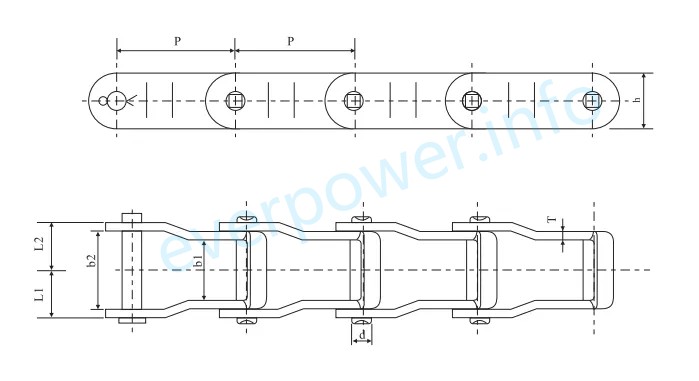

Specifications of 662H Stainless Steel Pintle Chain

The following details are specifications of stainless steel pintle chains.

Introduction of 662H Stainless Steel Pintle Chain

The 662H Stainless Steel Pintle Chain is a durable and reliable chain used in various industrial applications. Made from high-quality stainless steel, this chain offers excellent corrosion resistance and strength. With its unique structure and exceptional material properties, it provides reliable performance in demanding environments. The 662H Stainless Steel Pintle Chain is ideal for applications where durability and longevity are crucial.

Advantages of 662H Stainless Steel Pintle Chain

Our 662H stainless steel pintle chain offers several advantages over other types of chains on the market. One of the biggest advantages is its strength and durability. Made from high-quality stainless steel material, this chain is able to withstand extreme temperatures and harsh operating conditions without rusting or corroding.

Another advantage of this chain is its resistance to wear and tear. Its unique design allows it to handle heavy loads and high speeds without breaking or coming apart. This makes it an ideal choice for applications that require a reliable and long-lasting chain.

In addition, our 662H stainless steel pintle chain requires minimal maintenance, which is a significant advantage for businesses looking to reduce downtime and increase productivity. It is also easy to install and has a low noise level, making it an ideal choice for use in a wide range of industries.

Applications of 662H Stainless Steel Pintle Chain

- Food Processing Industry: The 662H Stainless Steel Pintle Chain is widely used in food processing applications such as conveying, cooling, and packaging. Its corrosion-resistant properties make it suitable for handling food products in damp and acidic environments.

- Brewery and Beverage Industry: This chain is commonly used in breweries and beverage plants for bottling, labeling, and packaging processes. Its durability and resistance to chemical exposure make it ideal for handling various types of bottles and containers.

- Pharmaceutical Industry: The 662H Stainless Steel Pintle Chain finds its application in the pharmaceutical sector for conveying, sorting, and packaging medications. Its hygienic properties and resistance to chemical sterilization methods ensure the chain's compliance with stringent industry regulations.

- Waste Water Treatment: This chain is commonly utilized in waste water treatment plants to transport sludge, screens, and filters. Its corrosion resistance and ability to withstand harsh environments make it suitable for continuous operation in water treatment facilities.

- Agricultural Sector: The 662H Stainless Steel Pintle Chain is used in agricultural equipment such as grain elevators, harvesters, and conveyors. Its strength and resistance to wear and tear allow for efficient handling of crops and materials in the farming industry.

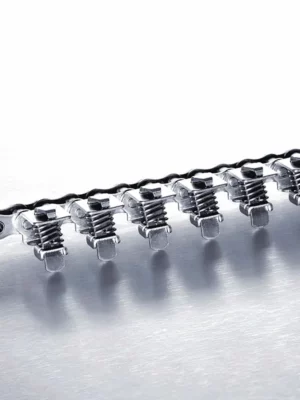

- Image:

Please note that the image provided is for reference purposes and may not depict the exact 662H Stainless Steel Pintle Chain model.

Maintenance Recommendations for 662H Stainless Steel Pintle Chain

To ensure the optimal performance and longevity of your 662H Stainless Steel Pintle Chain, proper maintenance is crucial. Follow these guidelines to clean and lubricate the chain correctly:

- Cleaning: Regularly remove dirt, debris, and any other contaminants from the chain. Use a brush or a cloth to carefully scrub the chain, ensuring that all the surfaces are thoroughly cleaned.

- Smering: Apply an appropriate lubricant to the chain to reduce friction and prevent wear. Use a lubricant specifically designed for stainless steel chains. Apply the lubricant evenly along the chain's entire length, making sure it penetrates into the rollers and bushings.

- Tension: Check the tension of the chain regularly. Ensure it is properly tensioned to avoid excessive wear and potential damage. Refer to the manufacturer's guidelines for the recommended tension settings.

- Inspectie: Periodically inspect the chain for any signs of damage, such as corrosion, bent or worn-out links. Replace any damaged parts immediately to prevent further problems.

By following these maintenance recommendations, you can keep your 662H Stainless Steel Pintle Chain in optimal condition, ensuring its performance and extending its lifespan.

Sprockets for Stainless Steel Chains

When selecting the appropriate sprockets for the 662H Stainless Steel Pintle Chain, there are several factors to consider. First, it is important to determine the desired speed ratio and torque requirements for your specific application. This will help in determining the number of teeth required on the sprocket.

Additionally, it is crucial to consider the pitch diameter and bore size of the sprocket. The pitch diameter should match the pitch of the chain, while the bore size should be compatible with the shaft diameter on which the sprocket will be mounted. It is recommended to choose sprockets made from high-quality stainless steel to ensure durability and resistance to corrosion.

At our company, we offer a wide range of sprockets to suit various needs and specifications. Our extensive selection includes different types, sizes, and configurations to accommodate diverse applications. Whether you require standard sprockets or custom-made options, we have the expertise and capabilities to fulfill your requirements.

Why Choose Our Stainless Steel Pintle Chains?

Our 662H Stainless Steel Pintle Chain is the ultimate choice for your chain needs. At RP Techniek BV, we take pride in offering a unique range of features that set us apart from the competition.

First and foremost, our stainless steel pintle chains are known for their exceptional quality. We use only the finest stainless steel materials, ensuring durability and longevity. Whether you need a chain for heavy-duty applications or corrosive environments, our 662H Stainless Steel Pintle Chain is built to withstand the toughest conditions.

In addition to superior quality, we are committed to providing excellent service to our customers. Our knowledgeable team is always ready to assist you and provide expert advice. We understand the importance of prompt delivery and strive to meet your timeline requirements.

Furthermore, we are proud to be the Netherlands sales agent for Ever-power Group. This partnership allows us to offer a wide range of stainless steel roller chains, ensuring that we can meet all of your chain needs. You can trust that our chains are of the highest quality and backed by the reputation of Ever-power Group.

Aanvullende informatie

| Editor | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...