In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Specifications for 462 Pintle Chain

- Chain Pitch: 2.609 inches

- Diameter of Barrel: 0.312 inches

- Ultimate Tensile Strength: 16,000 pounds

- Weight Per Foot: 2.09 pounds

- Material: Carbon Steel

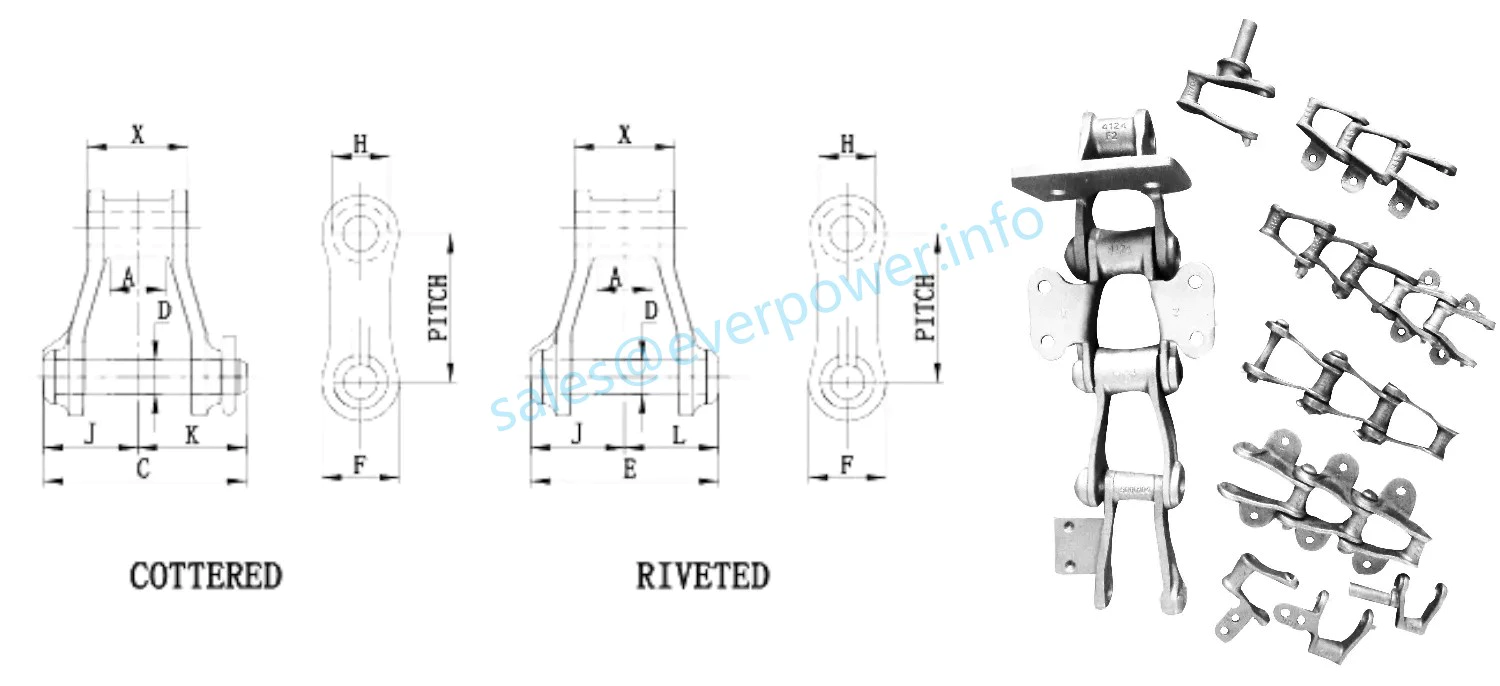

| 400 CLASS PINTLE CHAINS(DIMENSIONS IN INCHES) | ||||||||||||

| CHAIN NO |

PITCH IN INCHES |

WEIGHT PER FOOT LBS. |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | F | H | X | AVAILABLE ATTACHMENTS |

| 442 | 1.375 | 1.4 | 6.000 | 1000 | 0.62 | 2.03 | 0.31 | 1.88 | 0.75 | 0.56 | 1.06 | None |

| 445 | 1.63 | 1.5 | 6.000 | 1000 | 0.69 | 2.03 | 0.31 | 1.88 | 0.75 | 0.62 | 1.06 | A1,F2.K1 |

| 452 | 1.506 | 2 | 7.000 | 1250 | 0.62 | 2.22 | 0.38 | 2.06 | 0.84 | 0.69 | 1.09 | A88,D5.E1,K1 |

| 455 | 1.63 | 1.9 | 7.000 | 1260 | 0.69 | 2.22 | 0.38 | 2.06 | 0.84 | 0.62 | 1.12 | D15,F2.K1 |

| 462 | 1.634 | 2.5 | 8.800 | 1880 | 0.88 | 2.56 | 0.44 | 2.38 | 0.94 | 0.72 | 1.44 | A12.F2.K1 |

| 477 | 2.308 | 2 | 9.600 | 1640 | 0.69 | 2.38 | 0.44 | 2.25 | 1 | 0.72 | 1.25 | A22,D5.F2,F16.G1,G1 9.K1,K2 |

| 488 | 2.609 | 2.9 | 11.000 | 2130 | 0.94 | 2.94 | 0.44 | 2.75 | 0.94 | 0.88 | 1.62 | F2.G19.K1.K2 |

| 4103 | 3.075 | 5.7 | 27.000 | 4200 | 1.12 | 3.56 | 0.75 | 3.25 | 1.5 | 1.25 | 1.88 | F2.F29.K2 |

| 4124 | 4.06 | 7.3 | 28.600 | 4860 | 1.25 | 4.32 | 0.79 | 4.02 | 1.72 | 1.52 | 2.26 | F2.F8,K2 |

1. What is Pintle Chain?

Pintle chain is a type of roller chain that consists of interconnected links with pins and barrels. It is commonly used in heavy-duty applications that require high strength and durability.

2. Features of 462 Pintle Chain

462 Pintle Chain is specifically designed for demanding industrial environments. It offers the following features:

- High tensile strength

- Excellent resistance to wear and fatigue

- Low maintenance requirements

- Smooth operation

3. Applications of 462 Pintle Chain

462 Pintle Chain is widely used in a variety of industries for different applications, including:

- Agricultural machinery

- Conveyor systems

- Mining equipment

- Forest and wood processing

- Construction machinery

4. Advantages of 462 Pintle Chain

Here are some of the advantages that make 462 Pintle Chain a preferred choice:

- High load capacity

- Long service life

- Resistance to corrosion

- Ability to withstand harsh environmental conditions

5. Installation and Maintenance

To ensure optimal performance and longevity, proper installation and regular maintenance are crucial. Here are some guidelines:

- Ensure correct tensioning of the chain

- Lubricate the chain regularly

- Inspect for signs of wear or damage

- Replace any worn-out components promptly

6. Conclusion

Overall, 462 Pintle Chain is a reliable and durable solution for heavy-duty applications. Its high strength, wear resistance, and versatility make it an ideal choice for various industries. Invest in 462 Pintle Chain to enhance the performance and reliability of your machinery.

Choose Our Malleable Casting Chains

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. As a leading supplier of industrial chains, we take pride in offering the finest malleable cast iron chains, including the renowned 462 Pintle Chain.

Our malleable casting chains stand out with their exceptional quality and durability. Crafted with precision, these chains are designed to withstand heavy loads and demanding environments. With our commitment to excellence, we ensure that every chain meets the highest industry standards.

In addition to superior product quality, we also prioritize exceptional customer service. Our team of experts is dedicated to understanding your specific needs and providing personalized solutions. Whether it's technical support, efficient delivery, or after-sales assistance, we strive to exceed your expectations at every step.

At RP Techniek BV, we boast a robust production capability, equipped with state-of-the-art facilities and a skilled workforce. This enables us to meet large-scale demands while maintaining the highest level of craftsmanship. Our commitment to continuous improvement ensures that our malleable casting chains consistently meet the evolving needs of our clients.

Apart from malleable casting chains, we offer a wide range of other casting chains for various applications. With our diverse product portfolio, you can rely on us to provide the perfect chain solution for your specific requirements.

Please find the attached image showcasing our manufacturing excellence:

Choose RP Techniek BV for top-notch malleable casting chains and unrivaled customer service. Contact us today to discuss your chain needs and experience the Ever-power difference.

Sprockets for Sale

When it comes to finding the right chain sprocket to match your 462 pintle chain, it's important to consider a variety of factors. You'll want to think about the size of the sprocket, the number of teeth it has, and the material it's made from.

At our company, we offer a wide range of sprockets to meet your specific needs. We have sprockets made from high-quality materials like steel and cast iron, with teeth counts ranging from 20 to 80. Our sprockets are designed to work seamlessly with 462 pintle chain, ensuring a smooth and efficient operation.

Whether you need a sprocket for an industrial conveyor system or a farm implement, we've got you covered. Our experienced team can help you select the right sprocket for your application, and we can even customize a sprocket to meet your unique requirements.

So if you're in the market for a new sprocket, look no further than our selection of high-quality products. Contact us today to learn more about our sprockets for sale.

Aanvullende informatie

| Editor | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...