In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

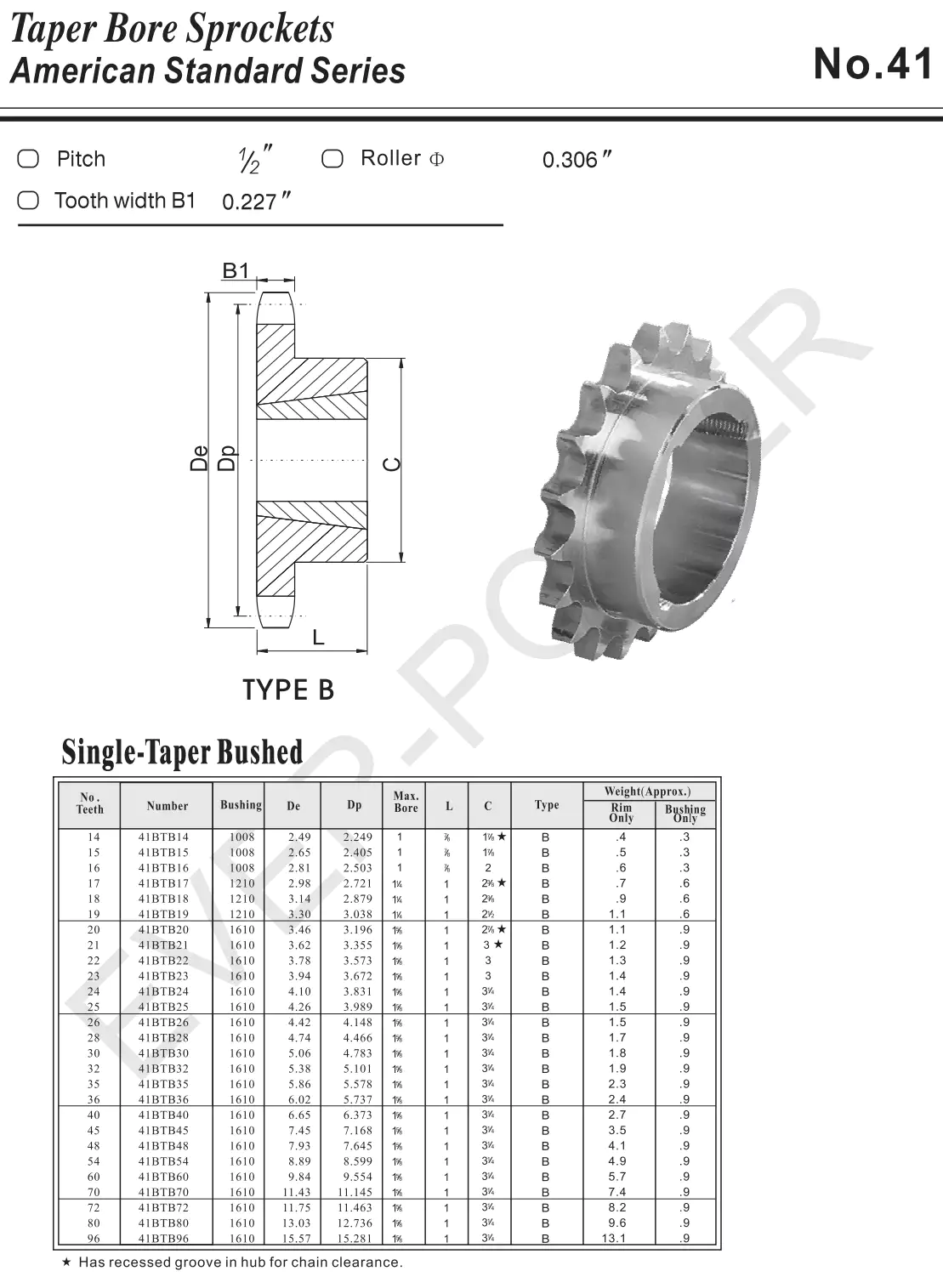

#41 1/2″ Taper Bore Sprocket

The #41 1/2″ Taper Bore Sprocket is designed for superior performance in various mechanical applications. Constructed from durable materials, it ensures longevity and reliability. This sprocket is ideal for precise power transmission in conveyor systems and machinery, providing efficient engagement with chains for optimal operation and minimal wear.

#41 1/2" Taper Bore Sprocket Specifications

#41 1/2" Taper Bore Sprocket is an essential component in power transmission systems. This sprocket is characterized by its tapered bore design and integrated hub, which allows for effortless installation on a shaft without the need for a keyway. It effectively transmits motion and power between shafts, making it a popular choice in various applications such as conveyor systems, agricultural machinery, and industrial equipment.

Characteristics and Functions of Taper Bore Sprocket

- Easy to Install: The tapered bore design significantly simplifies the installation process, eliminating the requirement for a keyway, which allows for quick and easy mounting and dismounting from the shaft.

- High Precision Positioning: Taper Bore Sprockets excel in providing precise positioning, which is crucial for ensuring accurate transmission of power and motion in mechanical systems.

- Wide Applicability: These sprockets are highly versatile and are widely utilized in conveyor systems, agricultural machinery, and various industrial applications due to their adaptable nature.

- Reliability: Taper Bore Sprockets are renowned for their dependability, making them a preferred choice for many power transmission applications.

- Low Maintenance Cost: With their robust design, these sprockets require minimal maintenance, which results in lower operational costs over time.

The straightforward installation and removal process of the Taper Bore Sprocket is a noteworthy advantage. It minimizes downtime while allowing for prompt maintenance when necessary. The high precision positioning ensures that power and motion are transmitted accurately, and its extensive applicability underscores its versatility for various applications. Its reliability, coupled with low maintenance requirements, contributes to its widespread popularity in power transmission systems.

Installation and Removal Process of Taper Bore Sprocket

Installing and removing a Taper Bore Sprocket involves a systematic approach, ensuring safety and functionality:

- Prepare Tools and Materials: Collect all necessary tools and materials, including the Taper Lock Bushing, the sprocket itself, and a torque wrench to ensure proper fastening.

- Clean Shaft and Sprocket Surface: Thoroughly clean both the shaft and sprocket surfaces to remove any dirt, debris, or contaminants that could interfere with a proper fit during installation.

- Place Taper Lock Bushing: Carefully position the Taper Lock Bushing onto the shaft, ensuring it is properly aligned with the bore of the sprocket.

- Install Sprocket: Gently slide the sprocket onto the bushing until it rests flush against the shoulder, providing a secure fit.

- Tighten Locking Nut: Using a torque wrench, tighten the locking nut to the manufacturer-recommended torque specifications, ensuring a solid and reliable installation.

By meticulously following these steps, you can achieve a secure and proper installation of the Taper Bore Sprocket. It is imperative to adhere to the manufacturer's guidelines and torque specifications to ensure long-lasting performance and safety of the assembly.

Manufacturing Process of Taper Bore Sprocket

The manufacturing of a Taper Bore Sprocket encompasses several critical stages that ensure the final product meets stringent quality standards:

- Prepare Raw Materials: Start by gathering the appropriate raw materials, which are typically metals like steel, known for their durability and strength.

- Cut Material: Proceed to cut the raw materials into the specified size and shape required for the sprocket.

- Forge or Cast: Depending on the production method selected, the material will either be forged or cast into the shape of the sprocket.

- Machine Teeth: Use precision cutting tools to machine the teeth of the sprocket, ensuring they meet the required specifications for functionality.

- Heat Treatment: Subject the sprocket to heat treatment processes to enhance its hardness and overall durability, which is vital for high-stress applications.

- Oppervlaktebehandeling: Application of surface treatments, such as plating or coating, is performed to improve resistance against corrosion and wear.

- Quality Inspection: Finally, a thorough inspection is conducted to ensure that the sprocket meets all quality and safety standards before being released for use.

Following these manufacturing steps scrupulously guarantees that the Taper Bore Sprocket is produced to the highest standards and specifications. Each phase of production is closely monitored to ensure compliance with both quality and performance benchmarks.

Understanding the intricacies associated with the #41 1/2" Taper Bore Sprocket, its features, and its operational processes can significantly enhance the efficiency and effectiveness of power transmission systems.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales representative for Ever-power Group in the Netherlands, specializing in the provision of high-quality sprockets and related products. Among our extensive range, the #41 1/2" Taper Bore Sprocket is highly regarded for its strength and precision engineering, making it an exceptional choice for a variety of industrial applications. Our offerings are designed to meet the demanding requirements of different sectors, ensuring optimal performance and extended service life.

In addition to our standard sprocket inventory, we also offer customized solutions that cater to the specific needs of our clients. We encourage customers to present their designs or samples for non-standard customization, ensuring that every unique requirement is met with great attention to detail.

Aanvullende informatie

| Edited | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...