In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

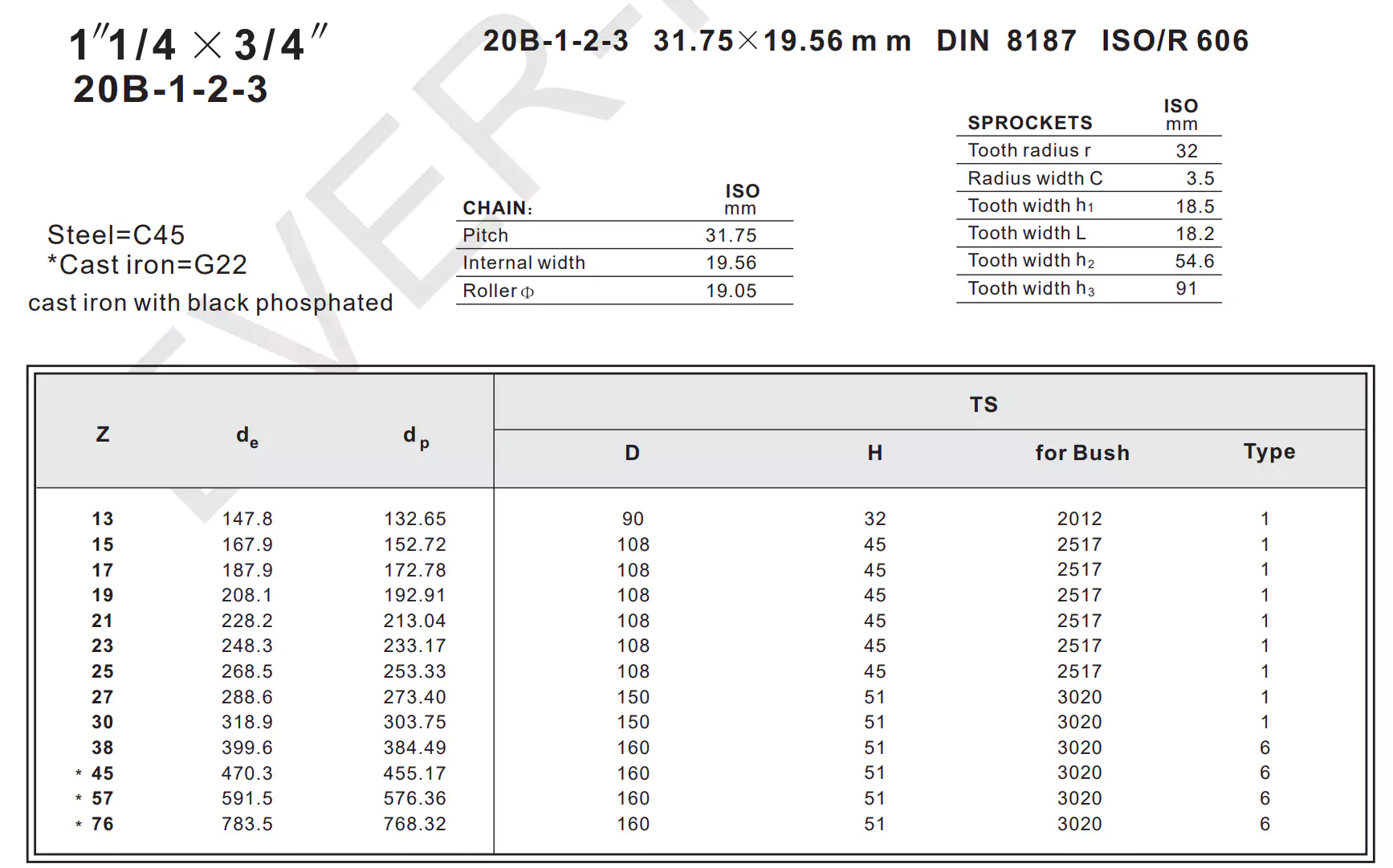

20B-1-2-3 1 1/4″ Taper Lock Sprocket

The 20B-1-2-3 1 1/4″ Taper Lock Sprocket is designed for reliable performance in various mechanical applications. With its robust construction and precision engineering, it ensures optimal power transmission and durability. This sprocket is easy to install and maintain, making it an excellent choice for enhancing the efficiency of your machinery.

Specifications of 20B-1-2-3 1 1/4" Taper Lock Sprocket

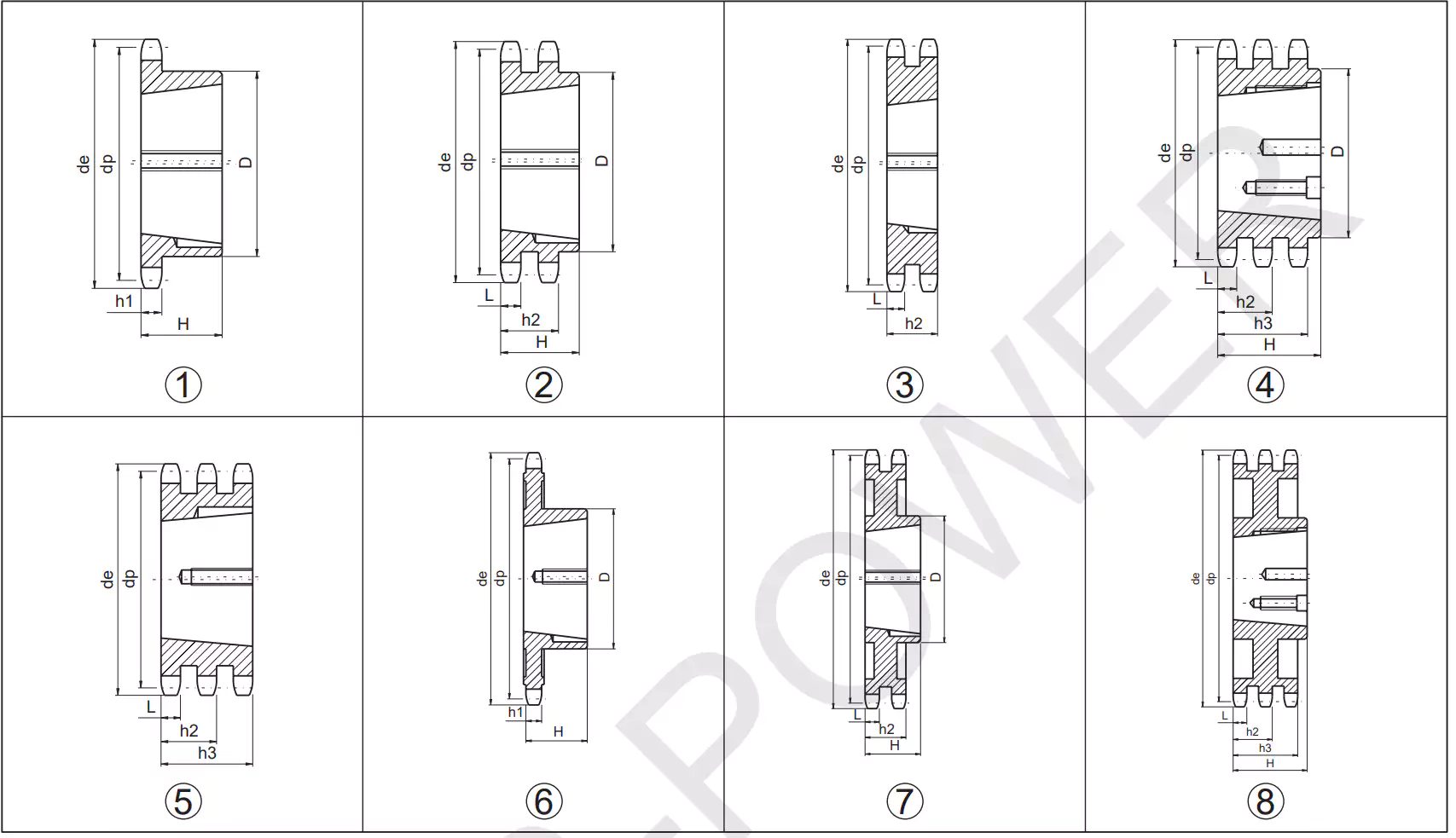

Taper Lock Sprocket 20B-1-2-3 European Standard is a renowned component in power transmission systems, recognized for its impressive taper lock design. This feature facilitates both quick installation and removal, which is particularly beneficial in time-sensitive environments. The sprocket excels in applications that demand precision and dependability, contributing to its popularity across various industries.

Features and Functions

- Easy Installation: The taper lock design significantly streamlines the installation process, which saves both time and effort for users, making it an efficient choice for various setups. - High Precision Positioning: This sprocket guarantees precise positioning of the chain, which is essential for efficient and effective power transmission throughout the system. - Wide Applicability: Taper lock sprockets are designed to accommodate a range of industrial applications, providing versatility and adaptability across different usage scenarios. - Reliability: The design and materials used in the sprocket ensure that it remains a reliable and durable component within power transmission systems, reducing the risk of operational failure. - Low Maintenance Cost: With minimal maintenance requirements, taper lock sprockets contribute to lower overall operating costs, making them a cost-effective solution.

Installation and Removal Process

To install a taper lock sprocket, adhere to the following step-by-step instructions: 1. Prepare Tools and Materials: Begin by gathering all essential tools and materials needed for the installation process to ensure a smooth workflow. 2. Clean Shaft and Sprocket Surface: It is crucial to clean the shaft and sprocket surfaces thoroughly, ensuring that they are free from any dirt, grime, or debris that could hinder performance. 3. Place Taper Lock Bushing: Insert the taper lock bushing carefully into the sprocket hub to ensure a secure fit before final assembly. 4. Install Sprocket: Slide the sprocket onto the shaft, making sure to align it accurately with the taper lock bushing for optimal performance. 5. Tighten Locking Nut: Use the appropriate tool to securely tighten the locking nut, which will hold the sprocket firmly in place during operation.

Sprockets Supplier in Netherlands

RP Techniek BV serves as a leading supplier for high-quality products and services tailored to meet diverse industrial needs within the Netherlands. One of our standout offerings includes the 20B-1-2-3 1 1/4" Taper Bore Sprocket, engineered for optimal performance and durability across a variety of applications. We utilize advanced technology and premium materials during manufacturing, ensuring reliability and extended longevity in challenging operational environments.

In addition to our standard offerings, we specialize in custom non-standard designs that cater to our clients' specific requirements. We encourage customers to present their drawings or samples for bespoke customization, guaranteeing that you receive the ideal tandwiel solution tailored to your precise needs.

Aanvullende informatie

| Edited | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...