In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

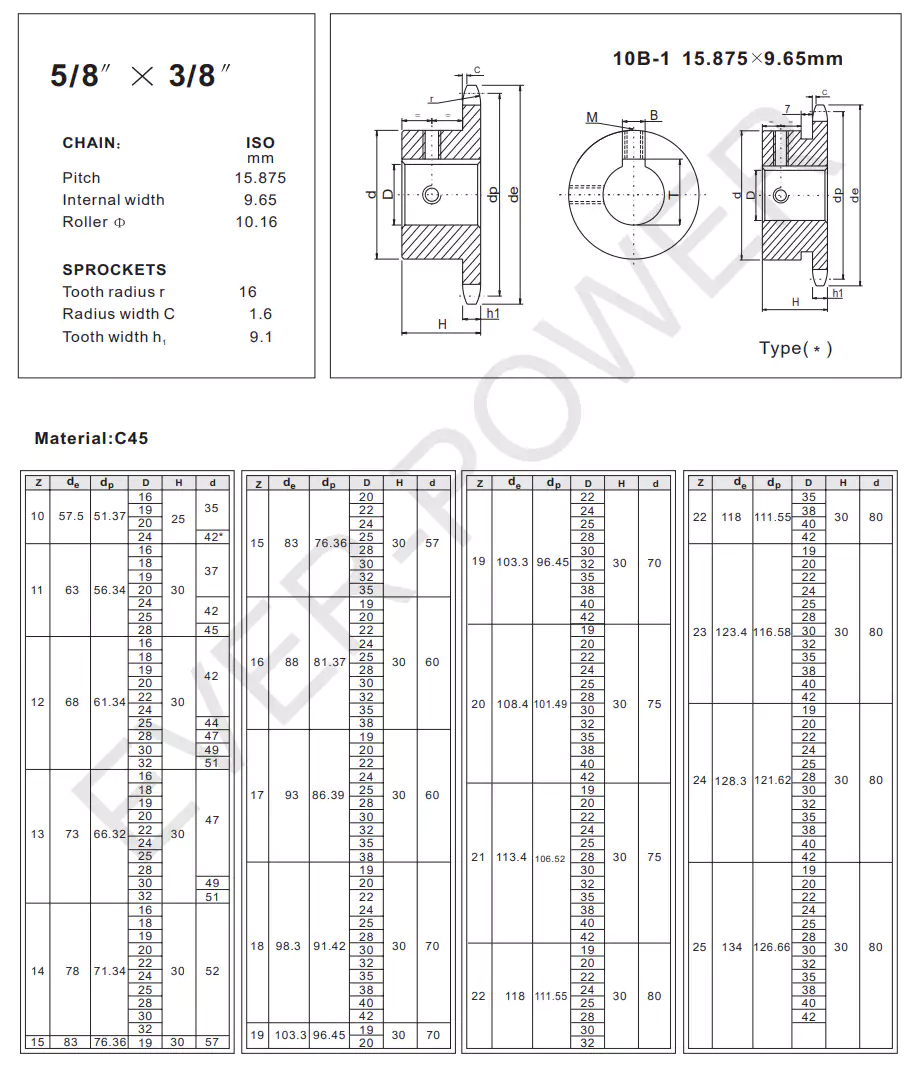

10B-1 Finished Bore Sprocket

The 10B-1 Finished Bore Sprocket is a precision-engineered component designed for optimal performance in various industrial applications. Made from high-quality materials, it ensures durability and reliability. Its finished bore allows for easy installation on shafts, making it an ideal choice for machinery that requires smooth and efficient power transmission.

Specifications of 10B-1 European Standard Finished Bore Sprocket

What is Finished Bore Sprocket?

Finished Bore Sprocket is a specialized type of sprocket designed with a pre-bored hole, which allows for straightforward installation onto various shafts. This design feature is particularly useful in different industrial contexts, as it enables efficient transmission of rotary motion between two separate shafts. They are essential components in many mechanical applications, ensuring smooth operation and reliability in the transfer of power.

Material and Manufacturing Process

- Material: High carbon steel, alloy steel, or stainless steel

- Productieproces:

- Material selection and cutting

- Punching and forging

- Machining, including turning, milling, and drilling

- Heat treatment, such as quenching, tempering, and surface hardening

- Surface treatment for rust prevention

- Quality inspection to ensure product reliability

Maintenance and Care of Sprockets

Ensuring the proper maintenance and care of sprockets is crucial for their longevity and optimal performance. Proper maintenance practices include daily inspections to check for any signs of wear or damage, as well as regular cleaning to eliminate dirt and debris that can hinder operation. Additionally, lubrication is vital to minimize friction and ensure smooth operation, along with periodic adjustments and calibrations as needed to maintain efficiency.

Common Issues and Solutions:

- Skipping teeth: It is important to check for misalignment or a worn-out chain, as these can lead to operational issues.

- Breakage: Inspecting for excessive load or material fatigue is essential to prevent failure.

- Wear: Replacing worn sprockets is necessary to maintain proper chain engagement and ensure effective transmission.

- Noise: Regular lubrication or adjustment of the sprocket can significantly reduce noise levels.

- Chain detachment: Verifying proper tension and alignment of the chain can help avoid detachment issues.

Other Types of Sprockets and Chains

Alongside Finished Bore Sprockets, we also provide a variety of other sprocket types, including:

- Taper lock sprockets

- QD sprockets

- Idler sprockets

Our extensive range of sprocket models and various chain types is designed to meet diverse operational requirements, ensuring you find the right solution for your needs.

Sprockets Supplier in the Netherlands

RP Techniek BV is proud to be the sales agent for Ever-power Group in the Netherlands, a respected manufacturer known for producing high-quality industrial components. We specialize in a wide range of products, including the 10B-1 European Standard Finished Bore Sprocket, which is engineered to fulfill the demanding requirements of various applications. Our sprockets are renowned for their durability, precision, and exceptional performance, making them ideal for industries that necessitate reliable power transmission solutions.

In addition to our standard sprockets, we offer customization services tailored to non-standard specifications to meet specific customer needs. We invite our valued clients to present their drawings or samples for bespoke solutions designed to address their unique requirements. Your satisfaction is our top priority!

Aanvullende informatie

| Edited | Zqq |

|---|

Blogs bijgewerkt

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...