Invoering

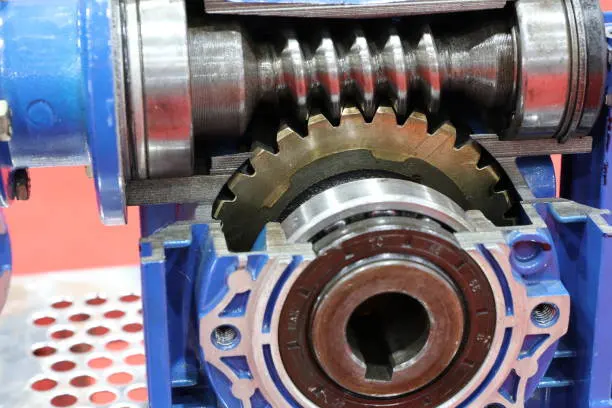

Worm gearboxes play a crucial role in various industries and applications where torque transmission and speed reduction are required. Specifically, the EPRV series small worm gearboxes have gained significant attention due to their compact size and high efficiency. In this article, we will delve into the testing procedures employed to ensure the quality and reliability of EPRV series small worm gearboxes.

1. Visual Inspection

Before conducting any performance testing, a visual inspection is carried out to check for any defects or abnormalities in the gearbox components.

2. Dimensional Accuracy Testing

The dimensional accuracy of the gears, shafts, and other crucial components is meticulously tested to ensure precise fitment and smooth operation.

3. Load Capacity Testing

Load capacity testing involves subjecting the EPRV series small worm gearboxes to various load conditions to determine their maximum load-bearing capacity and ensure they can handle the specified torque without failure.

4. Efficiency Testing

Efficiency testing is performed to measure the gearbox's ability to transmit power without significant losses. This test helps identify any inefficiencies or frictional losses within the gearbox.

5. Noise and Vibration Testing

Noise and vibration testing is crucial to ensure that the EPRV series small worm gearboxes operate quietly and smoothly, without excessive noise or vibration that could indicate internal issues or misalignment.

6. Temperature Testing

Temperature testing is conducted to evaluate the gearbox's thermal performance, ensuring it operates within safe temperature limits during extended usage.

7. Endurance Testing

Endurance testing involves subjecting the EPRV series small worm gearboxes to continuous operation under varying load conditions for an extended period. This test helps assess their long-term durability and reliability.

8. Environmental Testing

Environmental testing involves exposing the gearboxes to extreme temperatures, humidity, and other environmental factors to ensure they can withstand harsh conditions without degradation in performance or structural integrity.

9. Sealing and Leakage Testing

The sealing and leakage testing is performed to verify the effectiveness of the gearbox's seals and gaskets in preventing any oil or lubricant leakage during operation.

10. Material Analysis

Material analysis is conducted to ensure that the gearbox components are made from high-quality materials that possess the necessary strength, hardness, and wear resistance properties.

11. Gear Tooth Profile Testing

Gear tooth profile testing involves measuring the accuracy of the gear teeth to ensure proper engagement and minimal backlash.

12. Gearbox Assembly Inspection

During assembly inspection, each gearbox is carefully examined to ensure correct assembly and alignment of components, as well as proper lubrication.

13. Quality Control Documentation

All test results and inspection records are meticulously documented as part of the quality control process. This documentation ensures traceability and enables future analysis and improvement.

Elektrische motoren te koop

The relationship between gearboxes and electric motors is symbiotic, with both components complementing each other's functionality in various applications. Gearboxes provide the necessary torque multiplication and speed reduction required by electric motors, enabling them to operate efficiently in different load conditions. Conversely, electric motors drive the gearboxes, providing the power needed for motion and transmitting the rotational force to the load. The seamless integration and coordination between gearboxes and electric motors are essential for optimal performance and productivity.

Over ons

RP Techniek BV, the Netherlands sales agent of the Ever-power Group, is a leading transmission equipment manufacturer with a strong focus on research and development, manufacturing, and sales of speed reducers. With over 25 years of industry experience, we have established ourselves as a trusted provider of high-quality gearboxes, serving customers worldwide, especially in Europe, America, Africa, and Asia.

At RP Techniek BV, we pride ourselves on our state-of-the-art production facilities and robust manufacturing capabilities. We have invested in advanced production and testing equipment, allowing us to ensure the highest level of quality control throughout the production process. Our team consists of industry professionals and technicians who are dedicated to innovative research and development, constantly striving to deliver cutting-edge solutions.

Our commitment to excellence extends to our customer service, as we prioritize providing the best possible experience for our clients. We offer competitive prices without compromising on product quality or customer satisfaction. Our gearboxes find applications across various industries, including equipment, food, car washing, packaging, transmission, automation, and solar energy.

Vragen en antwoorden

Q1: What materials are typically used in manufacturing EPRV series small worm gearboxes?

A1: EPRV series small worm gearboxes are commonly manufactured using high-quality alloy steel, ensuring excellent strength and durability.

Q2: How are the EPRV series small worm gearboxes lubricated?

A2: EPRV series small worm gearboxes are typically lubricated with high-quality synthetic lubricants, specifically formulated for optimal performance and longevity.

Q3: Can EPRV series small worm gearboxes be customized for specific applications?

A3: Yes, EPRV series small worm gearboxes can be customized to meet specific requirements, including variations in gear ratios, shaft configurations, and mounting options.

Q4: What is the expected lifespan of EPRV series small worm gearboxes?

A4: With proper maintenance and regular lubrication, EPRV series small worm gearboxes can have a lifespan of several years, depending on the operating conditions and load requirements.

Q5: Are EPRV series small worm gearboxes suitable for high-speed applications?

A5: EPRV series small worm gearboxes are primarily designed for low-speed, high-torque applications. For high-speed applications, alternative gearbox solutions may be more suitable.

Bewerkt door: Zqq.