Afneembare ketting

Lightweight

Cost-Effective

High-Performance

Low Maintenance

CASTING DETACHABLE CHAINS are the first malleable iron chains extensively used across various industries. These chains are lightweight, cost-effective, and available in a comprehensive range of sizes, making them suitable for a broad range of applications. Whether handling light to medium loads at slow to intermediate speeds, Detachable Chains perform effectively in clean environments.

Detachable Chain Specifications

- Pitch Range: 0.902 to 4.063 inches, accommodating a wide variety of detachable chain applications.

- Material Options: Cast of malleable iron or Promal, with heat-treated carbon steel pins and case-hardened carbon steel bushings. For specific applications, stainless steel pins and bushings are available on request.

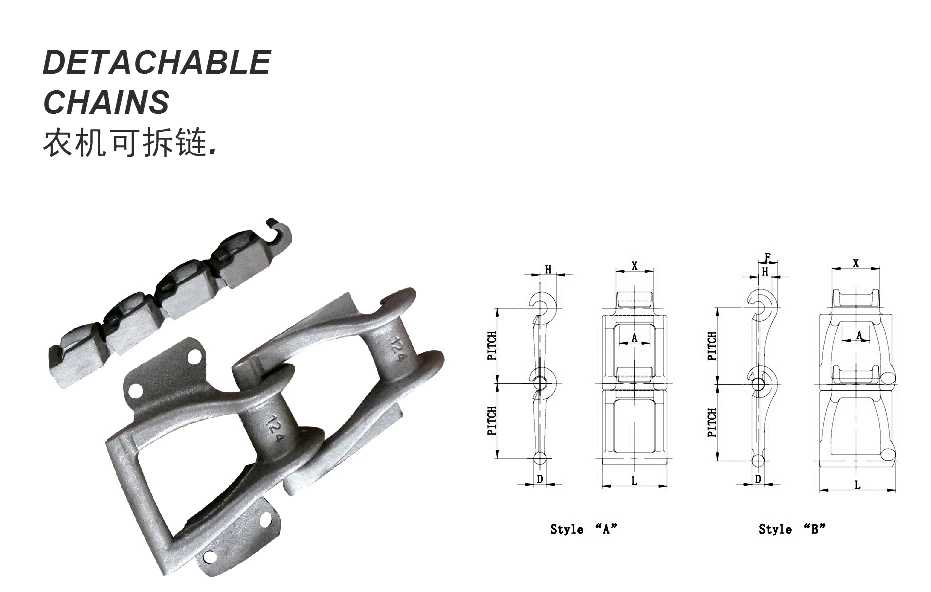

Two Link Styles Available

- Style A: Features a plain hook for standard service requirements.

- Style B: Equipped with a ribbed hook for heavy-duty applications.

| DETACHABLE CHAIN NO. |

PITCH IN INCHES |

HEIGHT PER FOOT LBS |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | F | H | Ik | X | AVAILABLE ATTACHMENTS |

| 25 | 0.902 | 2.4 | 700 | 120 | 0.38 | 0.14 | —— | 0.20 | 0.78 | 0.41 | A1-R.A1-L | ||

| 32 | 1.154 | 3.5 | 1,100 | 185 | 0.50 | 0.17 | —— | 0.25 | 0.97 | 0.58 | A1-R.A1-L.K1 | ||

| 34 | 1.398 | 4.0 | 1.300 | 220 | 0.50 | 0.19 | 1.25 | 0.56 | None | ||||

| 42 | 1.375 | 5.5 | 1.600 | 270 | 0.62 | 0.22 | —— | 0.28 | 1.28 | 0.77 | A1-R,A1-L.K1 | ||

| 45 | 1.630 | 5.2 | 1.700 | 285 | 0.69 | 0.22 | —— | 0.30 | 1.31 | 0.80 | A1-R.A1-L.K1 | ||

| 50 | 1.381 | 7.1 | 1.900 | 320 | 0.63 | 0.27 | 0.33 | 1.31 | 0.62 | None | |||

| 51 | 1.155 | 7.0 | 1.900 | 320 | 0.56 | 0.27 | —— | 0.36 | 1.25 | 0.67 | K1 | ||

| S51 | 1.136 | 7.B | 1.900 | 315 | 0.56 | 0.27 | —— | 0.30 | 1.06 | 0.64 | None | ||

| 52 | 1.506 | 8.0 | 2,300 | 385 | 0.62 | 0.27 | —— | 0.34 | 1.53 | 0.83 | A1.D5,K1 | ||

| 55 | 1.631 | 7.2 | 2,300 | 385 | 0.69 | 0.27 | —— | 0.36 | 1.41 | 0.81 | A1-R/L,D5-R/L,C1.F2,G27-R/L,K1,C | ||

| 57 | 2.308 | 8.7 | 2.900 | 485 | 0.75 | 0.27 | —— | 0.41 | 1.81 | 1.09 | A1-R,A1-L.F2 | ||

| 62 | 1.654 | 10.6 | 3.200 | 535 | 0.81 | 0.31 | 0.41 | 1.66 | 0.97 | A1-R/L,A12-R/L,05-R/L.K1,K2,F2 | |||

| 67 | 2.308 | 8.6 | 2.900 | 485 | 0.69 | 0.31 | 0.53 | 0.41 | 2.03 | 1.36 | None | ||

| 75 | 2.609 | 13.4 | 4,100 | 690 | 0.94 | 0.41 | —— | 0.44 | 2.09 | 1.12 | D5-R.D5-L | ||

| 77 | 2.297 | 14.5 | 3.600 | 600 | 0.69 | 0.39 | 0.61 | 0.36 | 2.22 | 1.42 | A1-R.A1-L.D5.F2,K1 | ||

| 78 | 2.609 | 18.8 | 5.500 | 920 | 0.94 | 0.42 | 0.66 | 0.44 | 2.62 | 1.62 | K1 | ||

| 88 | 2.609 | 24.0 | 6.400 | 1,070 | 0.94 | 0.48 | 0.78 | 0.44 | 2.75 | 1.78 | F2.K1 | ||

| 103 | 3.075 | 40.0 | 10,000 | 1,670 | 1.12 | 0.58 | 1.00 | 0.61 | 3.28 | 2.03 | F2.F8,K1,K2,F2 | ||

| 114 | 3.250 | 53.0 | 12.000 | 2.000 | 1.13 | 0.66 | 0.17 | 0.81 | 3.28 | 2.03 | None | ||

| 124 | 4.063 | 66.0 | 17.000 | 2,830 | 1.25 | 0.77 | 1.31 | 0.68 | 4.06 | 2.31 | F8.K1,K2 |

Material Options for Casting Detachable Chains

- Malleable Iron: Provides strength and durability.

- Promal (Duramal): For enhanced tensile strength, Promal links provide superior performance in demanding conditions.

Standard Components

- Carbon Steel Pins: Heat-treated for durability.

- Carbon Steel Bushings: Case-hardened for extended lifespan.

- Stainless Steel Options: Available for specific needs where corrosion resistance is required.

Key Features of Detachable Chains

Versatile Applications

Ideal for conveyor systems, elevators, and other machinery where smooth, reliable performance is required.

Easy Assembly & Disassembly

Constructed from one-piece interconnecting links, the chain can be easily assembled or disassembled by inserting links at the correct angle, then locking them into place.

Flexible Coupling Options

For applications with no chain take-up, coupler links can join chain ends into a continuous loop, minimizing slack and ensuring reliable operation.

Applications and Industry Solutions

- Agriculture: Detachable Chains are widely used in agricultural equipment like grain conveyors and elevators to handle light to medium loads.

- Food Processing: Suitable for food and beverage conveyor systems in clean environments where safe and efficient handling is required.

- Material Handling: Ideal for warehouses and logistics, providing precise control with minimal downtime.

- Mining & Construction: Promal Detachable Chains can endure heavy loads, making them suitable for harsh environments where material transport is critical.

Agriculture

Food Processing

Material Handling

Mining & Construction

Comparison with Other Chain Types

Detachable Chain vs. Roller Chain

- Cost: Detachable Chains are generally more cost-effective than roller chains, especially for light-duty applications.

- Ease of Assembly: Detachable Chains are easier to assemble and disassemble, making them ideal for applications requiring frequent maintenance or adjustments.

- Application Suitability: Roller chains are better suited for high-load, high-speed applications, whereas Detachable Chains excel in low- to medium-load environments with moderate speeds.

Detachable Chain vs. Welded Steel Chain

- Durability: Welded steel chains are more durable for heavy loads and extreme environments, while Detachable Chains offer better flexibility and cost advantages for lighter applications.

- Flexibility: Detachable Chains allow for easy disassembly and reassembly, unlike welded steel chains, which are more difficult to adjust once installed.

Detachable Chain Sprockets

Our detachable chain sprockets are designed to perfectly complement detachable chains, ensuring smooth and efficient operation. These sprockets are built for durability and precision, offering reliable performance in a variety of applications. Each sprocket is crafted to match the pitch sizes of detachable chains, enhancing compatibility and minimizing wear. Whether for conveyor systems, elevators, of drive applications, our sprockets provide optimal traction and long-lasting operation, even in demanding environments.

Why Choose Our Detachable Chains?

- Interchangeable Links: Our Detachable Chains adhere to standard industry specifications, ensuring compatibility with other manufacturers' chains, simplifying replacements and upgrades.

- Highly Customizable: From material options to attachment styles and sprocket availability, our Detachable Chains are designed to meet a variety of industrial needs.

Choosing our products means partnering with a company that prioritizes quality, reliability, and customer satisfaction. Our detachable chains En sprockets are manufactured to the highest industry standards, using premium materials like malleable iron and Promal, ensuring durability and long-lasting performance. We are backed by years of industry experience and a team of skilled engineers committed to providing innovative solutions tailored to your specific needs. Our customization options, technical support, and rigorous quality control processes guarantee you receive the best product every time. Trust us for dependable products that improve your operational efficiency and reduce downtime.