In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

WPO Single Stage Cast Iron Worm Reducer - Product Introduction

The WPO Single Stage Cast Iron Worm Reducer is a high-quality product developed based on the WD reducer. It is made of 45# high-quality steel and undergoes heat treatment processing which gives it excellent wear resistance and high bearing capacity. The reducer is mainly suitable for decelerating the transmission of various mechanical equipment such as plastics, metallurgy, beverage, mine, lifting and transportation, chemical construction, etc.

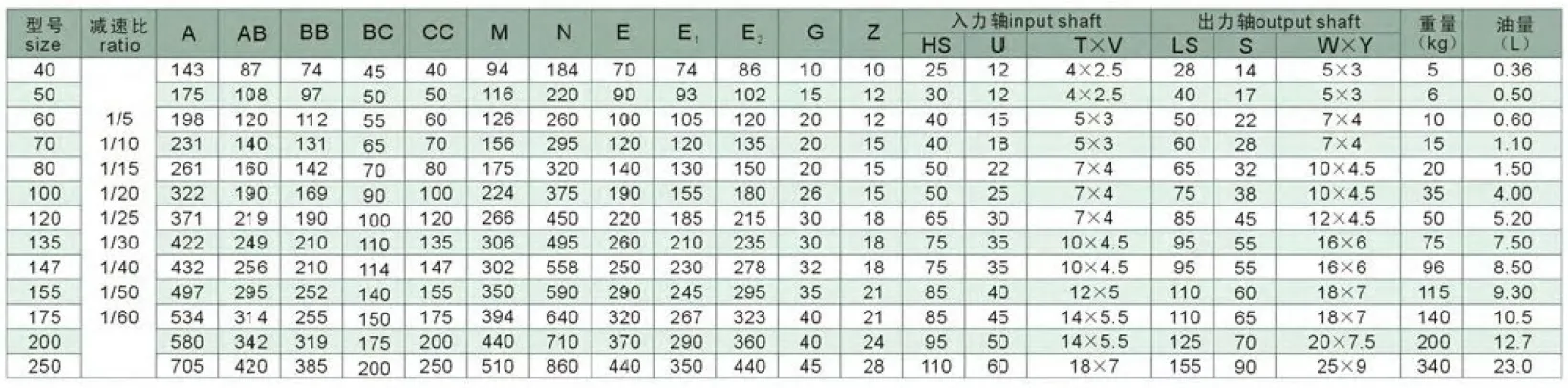

Specifications Parameter

The WPO series worm gearbox has the following specifications:

Features of WPO Series Worm Gearbox

The WPO series worm gearbox has the following features:

- Stable transmission, low vibration, impact, and noise

- Large reduction ratio, wide versatility, and suitable for use with various mechanical equipment

- Large transmission ratio can be obtained by single-stage transmission with a compact structure

- Most reducers have suitable self-locking properties and can save the brake device for mechanical equipment requiring brakes

- Good interfitting. National standards manufacture the worm and worm gear

It is important to note that the meshing friction loss between worm screw teeth and worm gear surface is relatively large, so the transmission efficiency is lower than that of the gear. It is recommended to maintain proper lubrication and cooling during use. Additionally, the gearbox has higher requirements for lubrication and cooling.

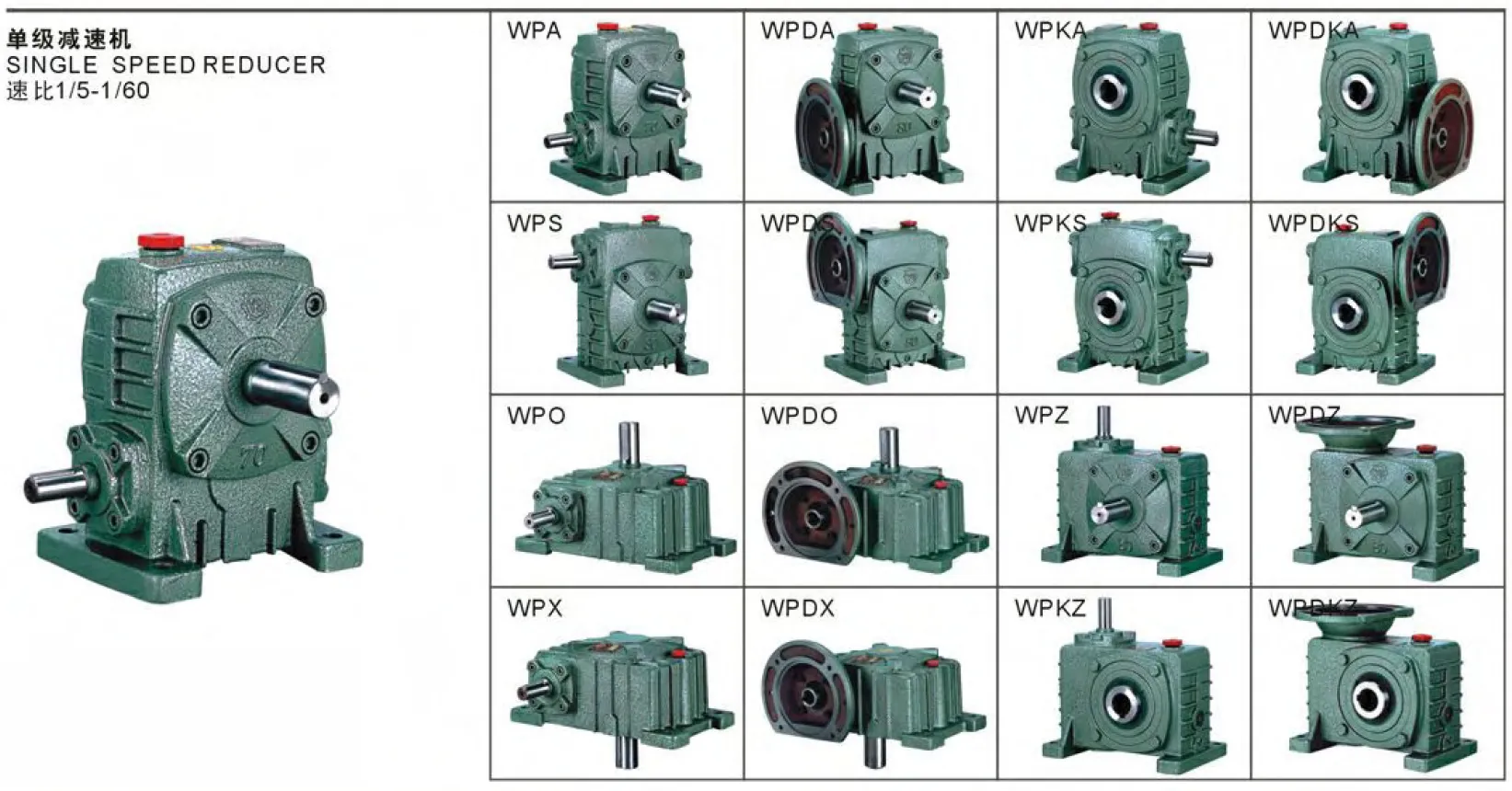

Other Series of Single Speed Gearbox

In addition to the WPO series worm gearbox, we also provide other series of single speed gearbox:

Precautions for Use

Before using the WPO series worm gearbox, please pay attention to the following precautions:

- Ensure that the reducer type structure, center distance specifications, transmission ratio, input shaft connection mode, output shaft structure, input shaft output shaft pointing, and rotation direction meet the requirements before use

- Fill in the suitable type and grade of lubricating oil according to the requirements specified in "Selection of Lubricating Oil Use" on the sample

- Control the appropriate amount of oil and timely oil change, especially paying attention to the first use of 100 hours after replacing new oil

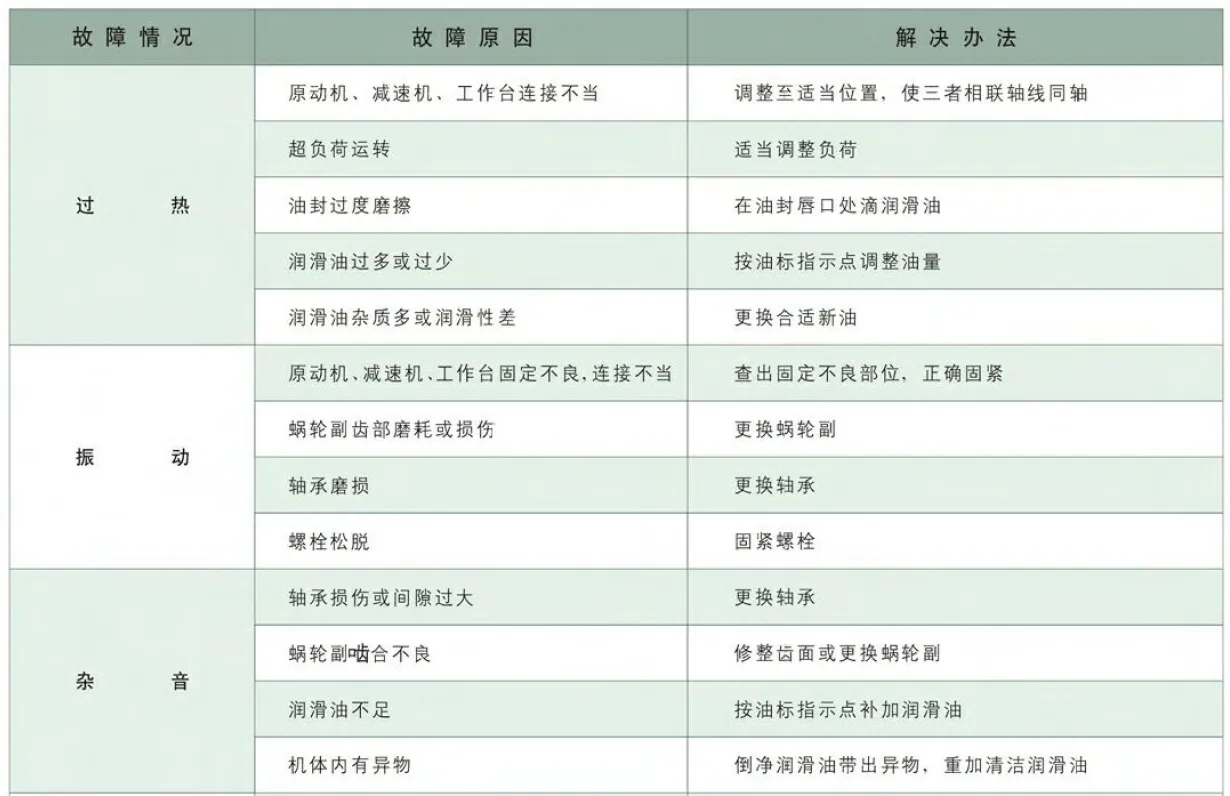

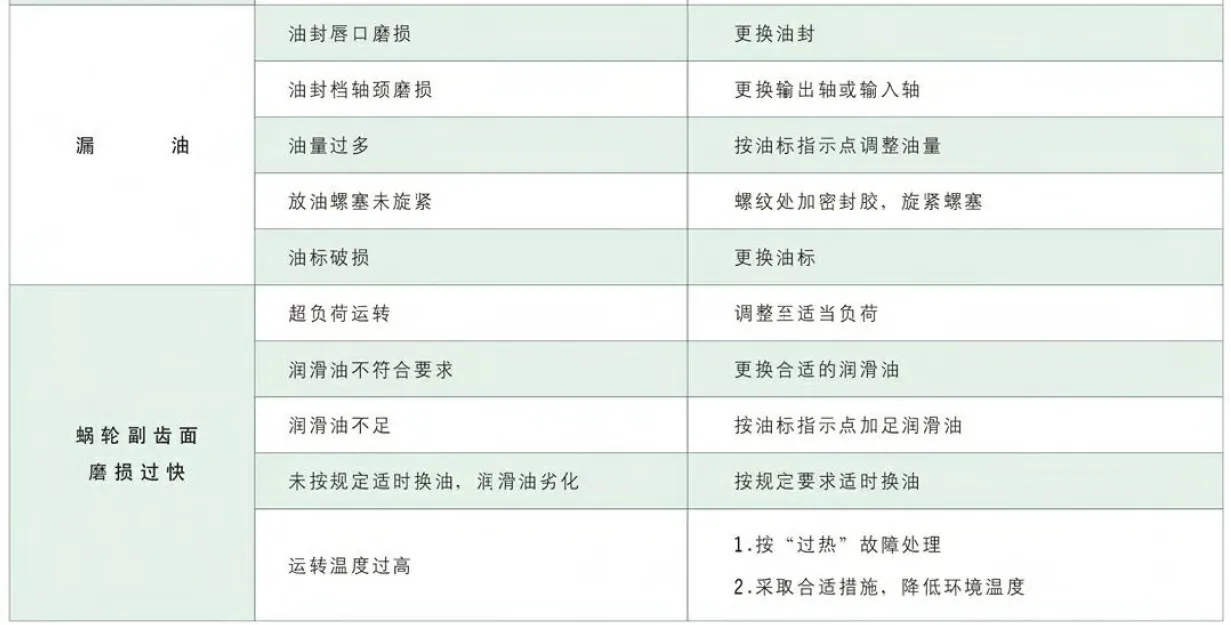

- If any abnormal situation occurs during use, it should be stopped for inspection in time and can be handled by referring to the table of "Fault Causes and Solutions."

Packing and Transportation

To ensure the integrity of product appearance, we will choose cartons, wooden pallets, and wooden pallets according to customer needs. Each reducer is manufactured and tested by strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time. We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

Oer Us

Ever-power is a comprehensive transmission equipment manufacturer integrating research and development, manufacturing, and sales of speed reducers. We have more than 25 years of experience in the design, production, manufacture, and sales of gearboxes, serving customers in Europe, America, Africa, Asia, etc., and have won the praise of the market. Our consistent mission and vision over the years, our company has introduced advanced production equipment and testing equipment at home and abroad, employing industry professionals and technicians to carry out innovative research and development and manufacturing, the use of standardized production management methods to strictly control every aspect of the production of reducers, over the years has been to provide customers with high-quality, high-energy-efficiency, high-stability production of crystals. Our gearboxes are widely used in equipment Industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry and so on. Welcome and trust by customers.

Elektryske Motors te keap

Electric motors and gearboxes are complementary to each other, and they play an important role in mechanical equipment. We also offer a variety of electric motors for sale that can be used in conjunction with our WPO Series Worm Gearbox. Our electric motors are of high quality and can provide reliable power transmission for your mechanical equipment.

Q&A

Q: What are the materials used in the WPO Single Stage Cast Iron Worm Reducer?

A: The WPO Single Stage Cast Iron Worm Reducer is made of 45# high-quality steel that undergoes heat treatment processing which gives it excellent wear resistance and high bearing capacity. The output shaft is made of medium carbon steel S45C, and the worm wheel is made of aluminum brass ALBC3 and FC20. The outer shell is made of cast iron FC20.

Q: What are the features of the WPO series worm gearbox?

A: The WPO series worm gearbox has stable transmission, low vibration, impact, and noise. It has large reduction ratio, wide versatility, and is suitable for use with various mechanical equipment. It also has good interfitting and most reducers have suitable self-locking properties and can save the brake device for mechanical equipment requiring brakes.

Q: What precautions should be taken when using the WPO series worm gearbox?

A: Before using the WPO series worm gearbox, ensure that the reducer type structure, center distance specifications, transmission ratio, input shaft connection mode, output shaft structure, input shaft output shaft pointing, and rotation direction meet the requirements. Fill in the suitable type and grade of lubricating oil according to the requirements specified in "Selection of Lubricating Oil Use" on the sample. Control the appropriate amount of oil and timely oil change, especially paying attention to the first use of 100 hours after replacing new oil. If any abnormal situation occurs during use, it should be stopped for inspection in time and can be handled by referring to the table of "Fault Causes and Solutions."

Q: What is the maximum oil temperature allowed for the WPO series worm gearbox?

A: The maximum oil temperature of the reducer is allowed to reach 95??. Under this temperature limit, as long as the oil temperature does not rise, it can be used safely.

Q: What is the mission and vision of Ever-power?

A: The mission and vision of Ever-power are to provide customers with high-quality, high-energy-efficiency, high-stability production of crystals. We have introduced advanced production equipment and testing equipment at home and abroad, employing industry professionals and technicians to carry out innovative research and development and manufacturing, the use of standardized production management methods to strictly control every aspect of the production of reducers.

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...