In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Details of Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125

Ynlieding

The Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125 is a critical component used in the manufacturing of steel and other metals. It is designed to provide a continuous flow of water to cool the molds and solidify the molten metal, resulting in high-quality and defect-free products. This article will explore the features and benefits of the SSP125 Water Slot Chain.

Construction

The SSP125 Water Slot Chain is made of high-quality stainless steel, ensuring corrosion resistance and durability. It is designed with a series of water slots that allow water to flow continuously to the molds, ensuring even cooling and solidification of the molten metal. The chain is also designed to withstand high temperatures and pressures, making it suitable for use in a variety of metallurgical applications.

Ûntwerp

The design of the SSP125 Water Slot Chain is optimized for maximum efficiency and performance. It features a series of interlocking links that provide a smooth and continuous flow of water to the molds, ensuring even cooling and solidification of the metal. The chain is also designed to be easily installed and maintained, minimizing downtime and maximizing productivity.

Benefits

Improved Product Quality

The SSP125 Water Slot Chain is designed to provide a continuous flow of water to the molds, ensuring even cooling and solidification of the molten metal. This results in high-quality and defect-free products, improving overall product quality and reducing scrap rates.

Increased Productivity

The efficient design of the SSP125 Water Slot Chain allows for faster cooling and solidification of the molten metal, reducing cycle times and increasing productivity. The chain is also designed to be easily installed and maintained, minimizing downtime and maximizing productivity.

Cost Savings

The use of the SSP125 Water Slot Chain can result in significant cost savings. By improving product quality and reducing scrap rates, manufacturers can save money on materials and production costs. Additionally, the increased productivity and reduced downtime can lead to further cost savings.

Applikaasjes

The SSP125 Water Slot Chain is suitable for use in a variety of metallurgical applications, including steelmaking, aluminum casting, and copper smelting. It is designed to withstand high temperatures and pressures, making it ideal for use in harsh environments.

Konklúzje

The Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125 is a critical component used in the manufacturing of high-quality metals. Its high-quality construction, efficient design, and numerous benefits make it an essential tool for any metallurgical operation. By investing in the SSP125 Water Slot Chain, manufacturers can improve product quality, increase productivity, and save money on production costs.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands. Our company takes pride in offering top-quality products and exceptional services. One of our standout products is the Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125.

Our unique selling points include:

1. Unmatched Product Quality: Our stainless steel metallurgy industry chains are manufactured using high-grade materials, ensuring durability and reliability in demanding industrial applications.

2. Superior Customer Service: We prioritize customer satisfaction and provide excellent pre- and post-sales support. Our dedicated team is always ready to assist you with any inquiries or technical assistance you may need.

3. Production Strength: Our state-of-the-art manufacturing facilities and advanced production processes enable us to meet large-scale demands without compromising on quality and efficiency.

In addition to the SSP125 chain, we offer a wide range of other stainless steel roller chains. Whether you require chains for industrial machinery, conveyor systems, or other applications, we have a solution to meet your specific needs.

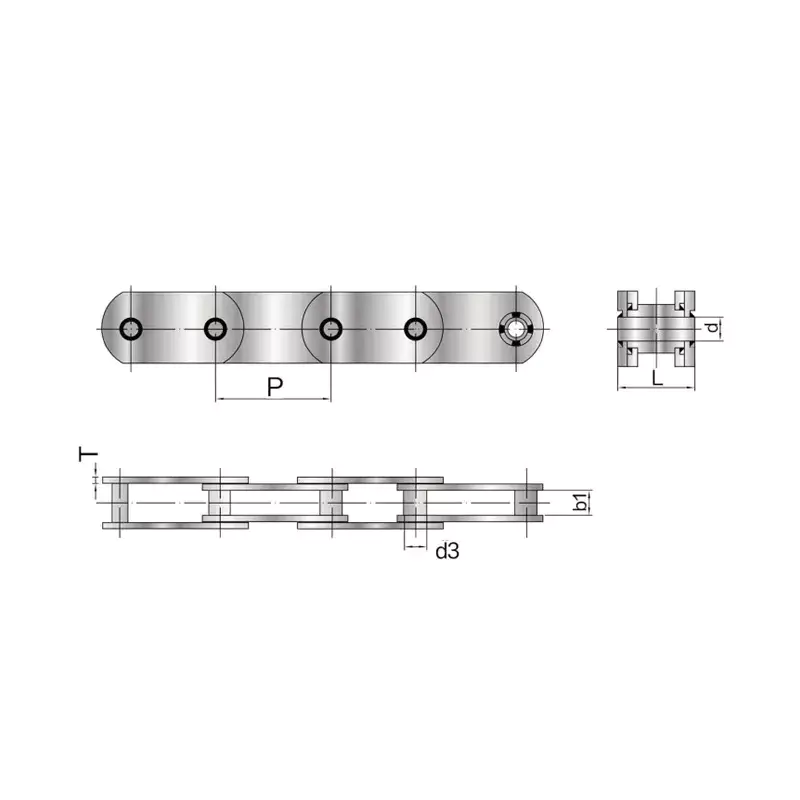

To give you a glimpse of our offerings, please find below an image of our chain:

Choose our stainless steel metallurgy industry chains for their unmatched quality, reliable performance, and exceptional customer support. Contact us today to discuss your requirements and experience the excellence of RP Techniek BV and the Ever-power Group.

How to Select Suitable Sprockets?

When it comes to selecting suitable sprockets for your Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125, there are a few important factors to consider. Firstly, it is essential to choose sprockets that are compatible with the chain's pitch and width. This ensures that the sprockets will fit snugly and securely with the chain and prevent any slipping or damage.

Another important consideration is the number of teeth on the sprocket. The number of teeth will determine the gear ratio of the machine, which has a significant impact on its performance. Choosing the right gear ratio is critical for achieving optimal efficiency and power output.

At our company, we offer a wide variety of sprockets to suit different needs and applications. Our sprockets are made from high-quality materials and are designed to be durable and long-lasting. We understand the importance of selecting the right sprockets for your machinery, which is why we provide expert advice and guidance to help you make the best decision.

In conclusion, when selecting suitable sprockets for your Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125, it is essential to consider factors such as compatibility, gear ratio, and durability. At our company, we offer a range of high-quality sprockets to meet your specific needs and requirements.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...