In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

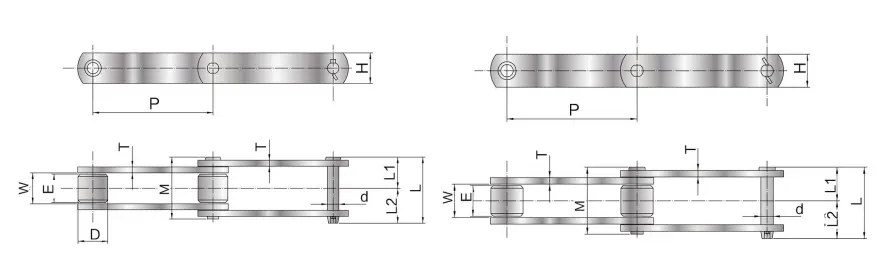

Specifications of SSRF03100 Stainless Steel Conveyor Chain

- Material: Stainless Steel

- Pitch: 31.75mm

- Breaking Load: 30.4KN

- Weight per meter: 9.5kg

- Pin Diameter: 9.5mm

- Roller Diameter: 19.05mm

- Plate Height: 41.28mm

- Plate Thickness: 6.35mm

| Chain No. | Roller Type |

Ultimate Tensile Strength |

Pitch | R roller | F roller | S roller | M/N roller | Width Between Inner Plates |

Plate | Pin | Weight Per Meter | Attachment Type | ||||||||||||||||||

| KN | P | D | E | D | K | E | e | Z | D | D | W | H | T | d | L1+L2 | L1 | L2 | R roller (kg/m) |

F roller (kg/m) |

S roller (kg/m) |

M/N roller (kg/m) |

A-1 K-1 |

A-2 K-2 |

Welded A-2 |

Welded A-3 |

SA-2 SK-2 |

G-2 | G-4 | ||

| SSRF03075 | R/F/S | 29 | 75 | 31.8 | 15.5 | 31.8 | 42 | 12 | 1.8 | 4.3 | 15.9 | - | 16.1 | 22 | 3.2 | 8 | 38 | 18 | 20 | 2.7 | 2.8 | 1.9 | - | R/F/S | R/F/S | R/S | ||||

| SSRF03100 | R/F/S | 29 | 100 | 31.8 | 15.5 | 31.8 | 42 | 12 | 1.8 | 4.3 | 15.9 | - | 16.1 | 22 | 3.2 | 8 | 38 | 18 | 20 | 2.3 | 2.4 | 1.7 | - | R/F/S | R/F/S | R/S | ||||

| SSRF430 | R/S | 54 | 101.6 | 38.1 | 19 | - | - | - | - | - | 20.1 | - | 22.8 | 25.4 | 4.8 (5.0) |

9.7 | 55 | 25.5 | 29.5 | 4.3 | 3 | R/S | R/S | R/S | ||||||

| SSRF05075 | S | 69 | 75 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | - | - | 4.2 | - | S | S | |||||

| SSRF05100 | R/F/S | 69 | 100 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | 5 | 5.2 | 3.7 | - | R/F/S | R/F/S | R/S | R/S | |||

| SSRF05150 | R/F/S | 69 | 150 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | 4.1 | 4.1 | 3.2 | - | R/F/S | R/F/S | R/S/M | ||||

| SSRF204 | S | 78 | 66.27 | - | - | - | - | - | - | - | 22.2 | - | 27 | 28.6 | ? 6.3 (6.0) |

11.3 | 65.5 | 31 | 34.5 | - | - | 5.6 | - | S | S | |||||

| SSRF450 | R/F/S/M | 78 | 101.6 | 44.5 | 23 | 44.5 | 55 | 18 | 2.5 | 6.5 | 22.2 | 25.4 | 27 | 28.6 | 6.3(6.0) | 11.3 | 65.5 | 31 | 34.5 | 6.8 | 7.2 | 4.6 | 4.9 | R/F/S/ M |

R/F/S/ M |

R/S/M | ||||

| SSRF08150 | R/F/S/M | 78 | 150 | 44.5 | 23 | 44.5 | 55 | 18 | 2.5 | 6.5 | 22.2 | 25.4 | 27 | 28.6 | ? 6.3 (6.0) |

11.3 | 65.5 | 31 | 34.5 | 5.5 | 5.6 | 4 | 4.2 | R/F/S/ M |

R/F/S/ M |

R/S/M | ||||

| SSRF650 | R/F/S/M | 78 | 152.4 | 50.8 | 26 | 50.8 | 65 | 20 | 3 | 7 | 25.8 | 31.8 | 30.2 | 38.1 | 6.3(6.0) | 11.3 | 69 | 32.5 | 36.5 | 7.7 | 8 | 6 | 6.4 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/S/M | S/M | ||

| SSRF10100 | R/S/M | 113 | 100 | 50.8 | 27 | - | - | - | - | - | 29 | 31.8 | 30 | 38.1 | 6.3 (6.0) |

14.5 | 69 | 33 | 36 | 9.8 | - | 6.8 | 7.1 | R/S/M | R/S/M | R/S/M | ||||

| SSRF10150 | R/F/S/M | 113 | 150 | 50.8 | 27 | 50.8 | 65 | 20 | 3 | 7 | 29 | 31.8 | 30 | 38.1 | 6.3 (6.0) |

14.5 | 69 | 33 | 36 | 79 | 8.1 | 5.9 | 6.1 | R/F/S/ M |

R/F/S M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF214 | R/S/M | 127 | 101.6 | 44.5 | 27 | - | - | - | - | - | 31.8 | 34.9 | 31.6 | 38.1 | 7.9 | 15.9 | 77.5 | 37.5 | 40 | 10.4 | - | 8.7 | 9.1 | R/S/M | R/S/M | R/S/M | ||||

| SSRF205 | S | 127 | 78.11 | - | - | - | - | - | - | - | 31.8 | - | 37.1 | 38.1 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | - | - | 10.4 | - | S | ||||||

| SSRF6205 | R/F/S/M | 186 | 152.4 | 57.2 | 32 | 57.2 | 70 | 25 | 3.5 | 9 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 12.1 | 12.4 | 9.3 | 9.6 | R/F/S/ M |

R/F/S M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF12200 | R/F/S/M | 186 | 200 | 65 | 32 | 65 | 80 | 24 | 4 | 8 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 11.4 | 11.9 | 8.4 | 8.7 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF12250 | R/F/S/M | 186 | 250 | 65 | 32 | 65 | 80 | 24 | 4 | 8 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 10.3 | 10.6 | 7.8 | 8 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF212 | R/S/M | 245 | 152.4 | 69.9 | 32.5 | - | - | - | - | - | 40.1 | 44.4 | 37.1 | 50.8 | 9.5(10.0) | 19.1 | 95.5 | 44.5 | 51 | 17.1 | - | 12.6 | 13.1 | R/S/M | R/S/M | R/S/M | ||||

| SSRF17200 | R/F/S/M | 245 | 200 | 80 | 44 | 80 | 100 | 34 | 5 | 12 | 40.1 | 44.5 | 51.4 | 50.8 | 9.5(10.0) | 19.1 | 109.5 | 51.5 | 58 | 18.8 | 19.8 | 12.3 | 12.6 | R/F/S/ M |

R/F/S/ M |

|||||

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...