In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Details

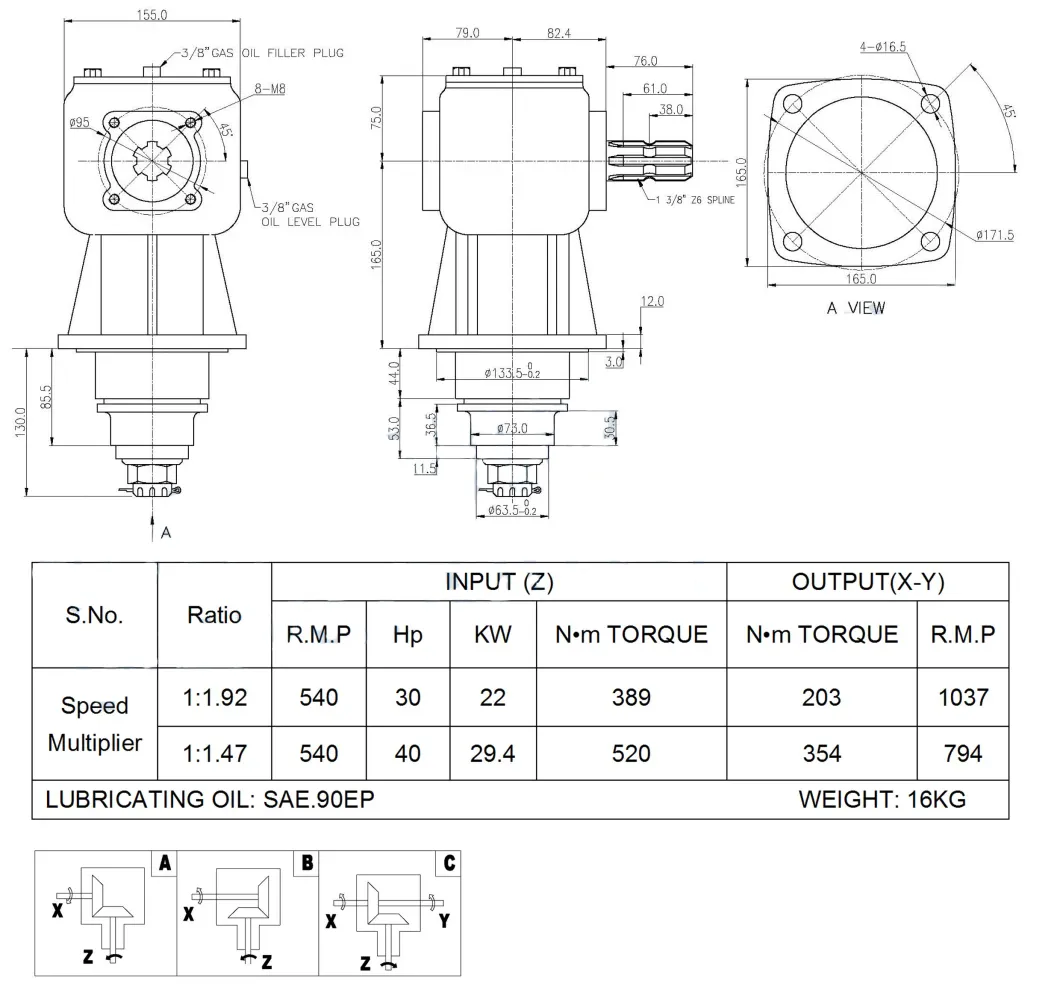

| Description |

Rotary Mower Gearbox Replacement of Comer Gearbox LF-205J (speed increasing)

|

|---|---|

| Oanfraach |

Mowers

|

| Consists of |

|

| Technical information |

|

| Max. input power |

22 kW

|

| Contains oil |

No

|

| Max. oil capacity |

0.8 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

| Gewicht |

16 kg

|

| Gear arrangement Increasing |

3

|

| Gear ratio |

1:1.92

|

| Input power kW / HP Increasing |

22 / 30 kW/HP

|

| Input shaft Increasing |

X

|

| Output Torque DaNm Increasing |

20 daNm

|

| Ratio Increasing |

1: 1.92

|

| Ratio Reducing |

1.92: 1

|

| Shaft X |

1 3/8" (6)

|

| Shaft Z |

ASA Z12 D.P. 8/16 Ø40

|

Ynlieding

Rotary mower gearboxes are an essential component of many agricultural and industrial mowers. These gearboxes are responsible for transferring power from the mower's engine to the blades, enabling the blades to cut through tough grass and vegetation. The Comer Code LF205J is a popular gearbox used in many rotary mowers, but over time, it may wear out and require replacement. In this article, we will discuss the replacement of the Comer Code LF205J with a new gearbox, including the process and benefits of replacement.

Understanding the Comer Code LF205J

The Comer Code LF205J is a high-quality rotary mower gearbox that is known for its durability and efficiency. It is commonly used in many agricultural and industrial mowers, and it is known for its ability to withstand high levels of stress and wear. However, even the best gearboxes will eventually wear out over time, especially with heavy use. Signs of wear may include unusual noises, decreased power, or difficulty cutting through tough vegetation.

The Replacement Process

The replacement of a Comer Code LF205J gearbox is a straightforward process that can be completed by a qualified technician. The first step is to remove the old gearbox from the mower. This may involve removing the blades and other components to access the gearbox. Once the old gearbox is removed, the new gearbox can be installed in its place. The technician will need to ensure that the new gearbox is properly aligned and secured in place. Once the new gearbox is installed, the blades and other components can be reattached, and the mower can be tested for proper operation.

The Benefits of Replacement

Replacing a worn-out Comer Code LF205J gearbox with a new one offers several benefits. First, a new gearbox will restore the mower's power and cutting ability, enabling it to handle tough vegetation with ease. Second, a new gearbox will be more reliable and durable than an old, worn-out one, reducing the risk of breakdowns and other issues. Third, a new gearbox can improve the overall performance and efficiency of the mower, reducing fuel consumption and operating costs.

Choosing the Right Replacement Gearbox

When selecting a replacement gearbox for a Comer Code LF205J, it is important to choose a high-quality, reliable product. Look for gearboxes that are made from durable materials, such as hardened steel. Consider the gear ratio and other specifications to ensure that the replacement gearbox is compatible with the mower's engine and other components. It is also important to choose a replacement gearbox that is backed by a manufacturer's warranty, which can provide peace of mind and protection against defects or other issues.

Konklúzje

The Comer Code LF205J is a popular and reliable rotary mower gearbox, but even the best gearboxes will eventually wear out over time. When this happens, replacement with a new, high-quality gearbox is the best option. The replacement process is straightforward and can be completed by a qualified technician. By choosing the right replacement gearbox, mower owners can restore their mower's power and efficiency, reduce the risk of breakdowns, and enjoy reliable, efficient mowing for years to come.

Why Choose Our Agricultural Gearboxes?

RP Techniek BV is the authorized sales agent for Ever-power Group in the Netherlands. Our company takes pride in offering high-quality agricultural gearboxes, with a focus on the replacement of Comer Code LF205J in Rotary Mower Gearboxes.

One of our unique selling points is the exceptional product quality we provide. Our gearboxes are designed to withstand the demands of agricultural applications, ensuring durability and reliability. Moreover, we prioritize customer satisfaction and offer outstanding company services, including prompt technical support and efficient after-sales service.

At RP Techniek BV, we also emphasize our production capabilities. With state-of-the-art manufacturing facilities and a team of skilled professionals, we ensure the production of top-notch agricultural gearboxes that meet international standards.

In addition to gearboxes, we offer a wide range of other agricultural machinery parts and transmission components. Our diverse product catalog caters to various farming needs, providing farmers with a comprehensive solution for their equipment requirements.

PTO Shafts for Agricultural Gearboxes

The PTO shaft plays a critical role in the functioning of agricultural gearboxes. Rotary mower gearboxes, such as the Comer Code LF205J, require PTO shafts to transfer power from the tractor to the gearbox. Without a properly functioning PTO shaft, the gearbox cannot operate effectively.

At our company, we offer a wide range of PTO shafts for agricultural gearboxes, including the Comer Code LF205J. These PTO shafts are designed to meet the highest industry standards, ensuring durability and reliability in the most demanding agricultural environments.

Whether you need a replacement PTO shaft or are looking to upgrade your existing equipment, our selection of high-quality PTO shafts will meet your needs. With our commitment to customer satisfaction, you can trust us to provide you with the best possible product and service.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...