In modern industrial machinery, the transmission chain is a key component that connects the power source and the actuator. Its design and performance directly affect the overall efficiency, reliability and service life of the machinery. Basic Structure and Function of...

Details

| Produkt Beskriuwing |

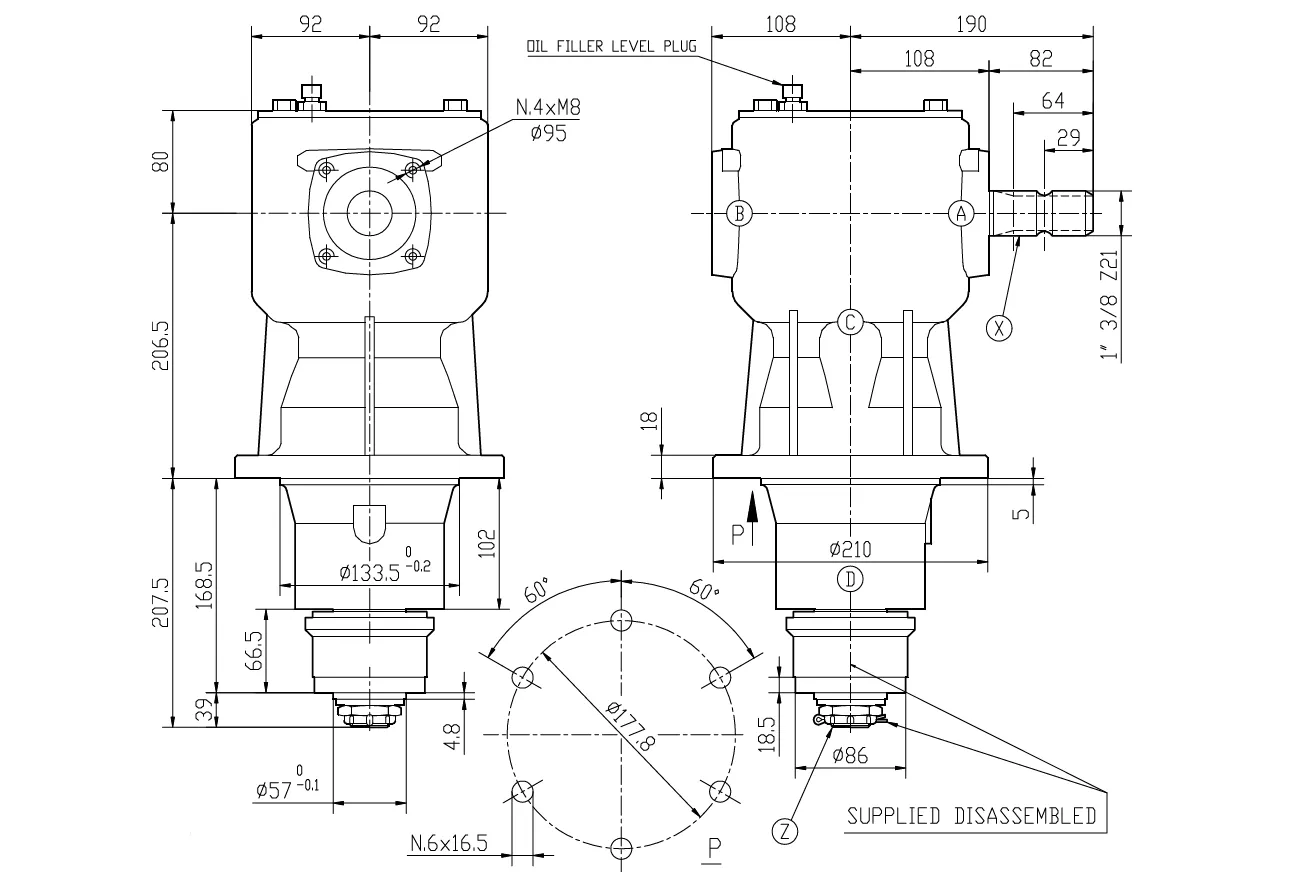

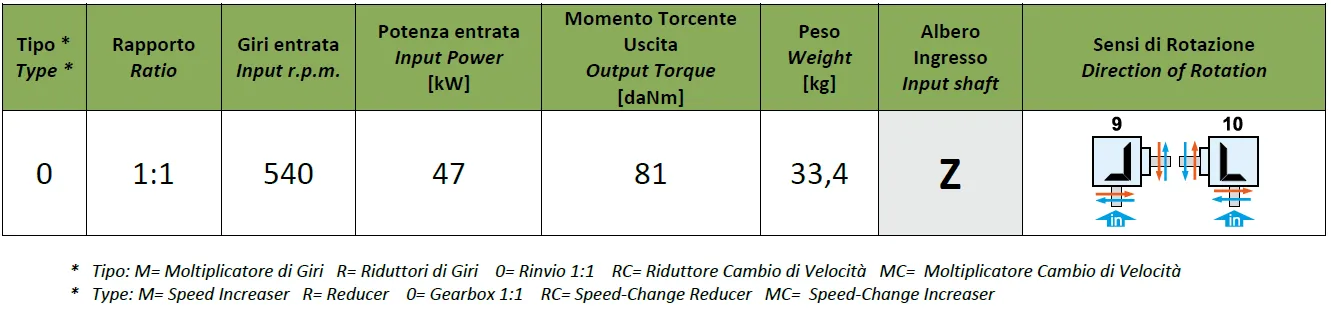

Rotary Mower Gearboxes - Replacement of Comer Gearbox LF-149B 1:1

|

|---|---|

| Product details |

|

| Max. input power |

47 kW

|

| Contains oil |

No

|

| Max. oil capacity |

0.8 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

| Gewicht |

33.4 kg

|

| Gear arrangement Increasing |

3

|

| Gear ratio |

1:1

|

| Input power kW / HP Increasing |

47 / 55 kW/HP

|

| Input shaft Increasing |

Z

|

| Output Torque DaNm Increasing |

81 daNm

|

| Ratio Increasing |

1: 1

|

| Ratio Reducing |

1: 1

|

| Shaft Z |

1 3/8" (21)

|

Ynlieding

Rotary Mower Gearboxes play a vital role in ensuring efficient and effective cutting of grass. Comer Code LF-149B 1:1 is a commonly used gearbox in rotary mowers. However, due to wear and tear, it may require replacement. In this article, we will discuss the replacement of Comer Code LF-149B 1:1 with a new gearbox.

Determine the Replacement Gearbox

The first step in replacing Comer Code LF-149B 1:1 is to determine the replacement gearbox. The replacement gearbox should match the specifications and dimensions of the original gearbox. It is recommended to consult the manufacturer's manual or seek professional advice to ensure the compatibility of the replacement gearbox.

Removal of Comer Code LF-149B 1:1

Before removing the old gearbox, ensure that the rotary mower is turned off and the blades are disengaged. The next step is to remove the bolts and nuts that secure the gearbox to the mower deck. The gearbox can then be lowered and detached from the mower. Care should be taken to avoid damaging other parts of the mower during this process.

Installation of the Replacement Gearbox

The installation of the replacement gearbox involves reversing the removal process. The new gearbox should be carefully attached to the mower deck using the bolts and nuts that secured the old gearbox. The gearbox should be securely fastened to the mower deck to prevent any movement during operation. Again, it is recommended to consult the manufacturer's manual or seek professional advice to ensure proper installation.

Lubrication of the Replacement Gearbox

After installation, the replacement gearbox should be lubricated following the manufacturer's guidelines. Proper lubrication is essential to ensure the smooth operation of the gearbox and prolong its lifespan. It is recommended to use high-quality lubricants that are compatible with the gearbox.

Testing the Replacement Gearbox

Once the replacement gearbox is installed and lubricated, the mower should be tested to ensure the gearbox is functioning properly. This involves engaging and disengaging the blades and running the mower for a short period to check for any unusual sounds or vibrations. Any issues should be addressed promptly to avoid further damage to the mower or gearbox.

Konklúzje

In conclusion, the replacement of Comer Code LF-149B 1:1 is crucial to ensure the efficient and effective operation of the rotary mower. The replacement gearbox should match the specifications and dimensions of the original gearbox, and proper installation, lubrication, and testing should be carried out to ensure the smooth operation of the mower. Following the manufacturer's guidelines and seeking professional advice can help ensure the successful replacement of the gearbox.

Why Choose Our Agricultural Gearboxes?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We pride ourselves on providing high-quality agricultural gearboxes, including the Rotary Mower Gearbox - Replacement of Comer Code LF-149B 1:1. Our gearboxes are designed to meet the highest industry standards, ensuring exceptional performance and durability.

What sets us apart is our commitment to customer satisfaction. We prioritize delivering top-notch products and excellent service to our valued customers. Our team of experts is dedicated to assisting you in finding the perfect gearbox solution for your agricultural needs.

In addition to our agricultural gearboxes, we offer a wide range of other farm machinery parts and transmission components. From belts to pulleys and everything in between, we have you covered. With our extensive product selection, you can find all the necessary components to keep your farm running smoothly.

With years of experience in the industry, we have established a strong reputation for our manufacturing capabilities. Our state-of-the-art production facilities enable us to maintain rigorous quality control measures, ensuring that every gearbox meets our stringent standards.

PTO Shafts for Agricultural Gearboxes

PTO shafts play a critical role in connecting agricultural gearboxes to the power source of tractors during the operation of rotary mowers. As such, it is essential to ensure that they are compatible with the gearbox being used. The Comer Code LF-149B 1:1 is a popular rotary mower gearbox model that requires specific dimensions for the PTO shaft.

At our company, we offer a range of agricultural PTO shafts, including those that are compatible with the Comer Code LF-149B 1:1 gearbox. Our PTO shafts are made from high-quality materials and are designed to withstand the rigors of heavy-duty use in the field. They are available in various lengths to meet the specific requirements of different agricultural applications.

Whether you are a farmer looking to replace a damaged PTO shaft or a manufacturer of agricultural equipment searching for a reliable supplier, we have got you covered. Our PTO shafts are competitively priced and come with a warranty for your peace of mind.

Oanfoljende ynformaasje

| Editor | Zqq |

|---|

Blogs Updated

German Gearbox Lubrication and Maintenance

As a crucial part of mechanical equipment, the gearbox's lifespan and performance have a direct impact on the system's overall operational efficiency. Maintenance and lubrication are crucial steps in ensuring the gearbox operates steadily over the long run. The Value...

The Working Principle of the Speed Reducer in Belgium

The reducer is an indispensable key equipment in modern industry, widely used in various mechanical transmission systems. Understanding the working principle of the reducer not only helps to select and use the reducer correctly but also improves the operating...